Glass substrate recognition chip and manufacturing method therefor

A manufacturing method and chip technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting test pad space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

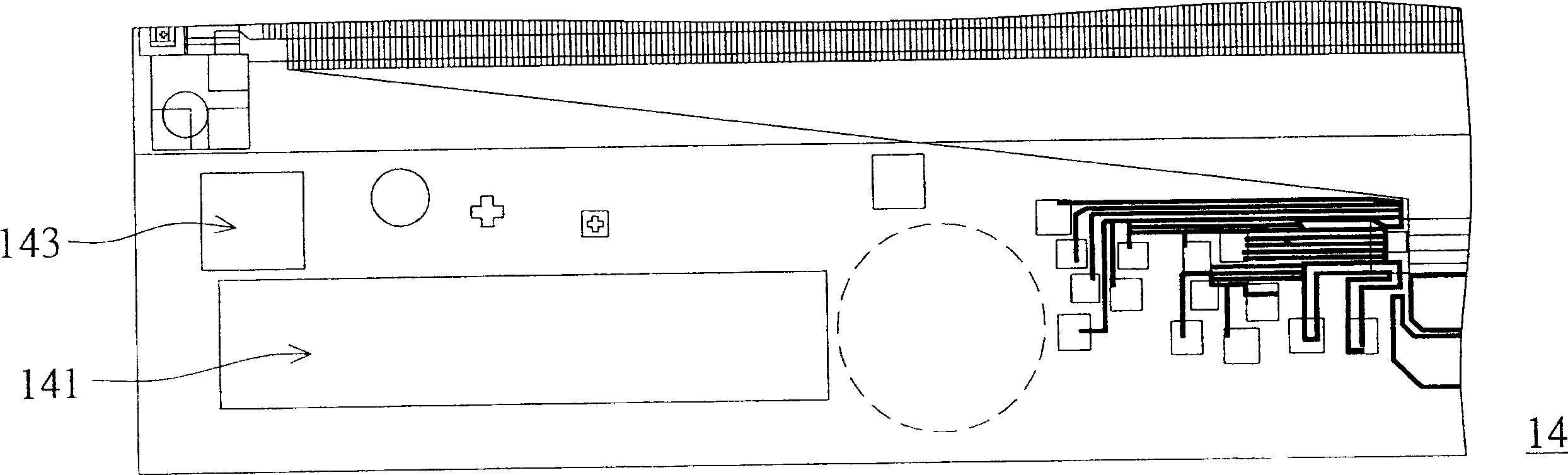

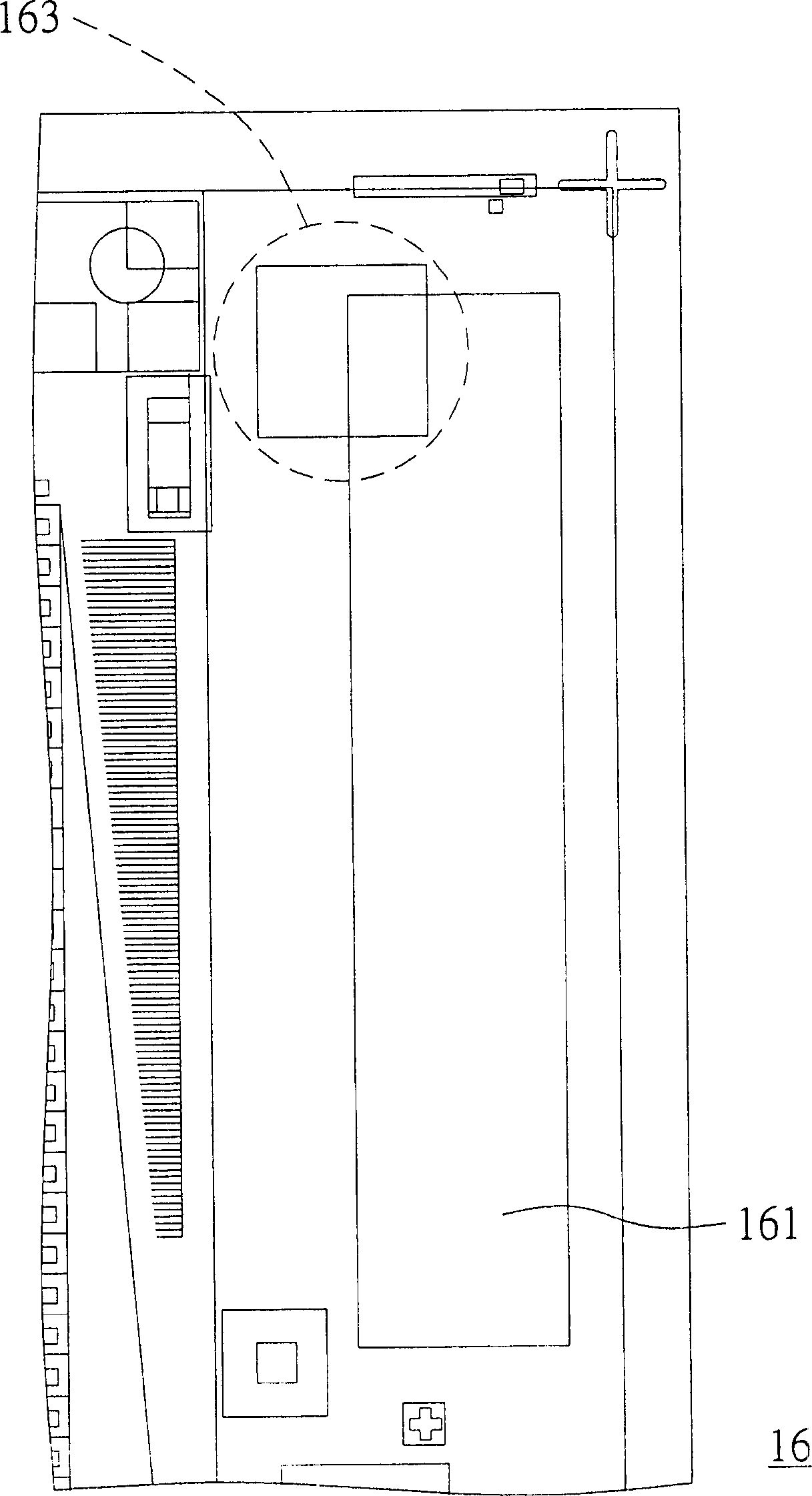

[0022] The invention integrates a plurality of test pads and identification chips, and manufactures identification chips with testing functions through a special manufacturing method, thereby achieving the purpose of saving space. The manufacturing method and finished product of the identification chip of the present invention will be described below with preferred embodiments.

[0023] Please refer to Figures 3A-8B , which shows a method for manufacturing an identification chip with testing function according to a preferred embodiment of the present invention. Figure 3A , 4A , 6, 7A, 8A are side views. Figure 3B for Figure 3A top view of . Figure 4B for Figure 4A top view of . Figure 7B for Figure 7A top view of . Figure 8B for Figure 8A top view of .

[0024] First, a substrate 31 is provided, and a metal layer 33 is formed on the substrate 31, such as Figure 3A , 3B shown. Next, the metal layer 33 is etched to form a plurality of independent metal bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com