Device for producing tubular meshbelt that can be turned inside out

A cylindrical, control device technology used in weaving auxiliary equipment, looms, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

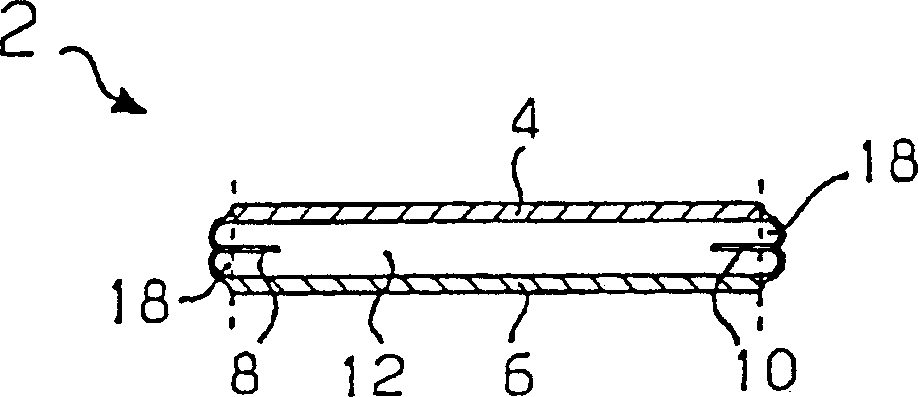

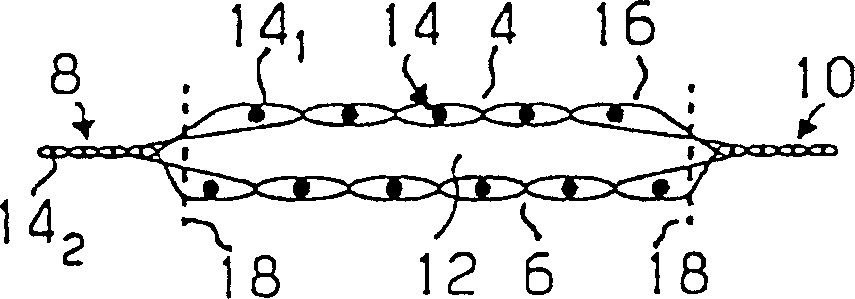

[0025] Figures 1 to 3 A first type of webbing 2 is shown, which consists of an upper fabric layer 4 and a lower fabric layer 6 , which are connected to one another by selvedges 8 and 10 on both sides and form a hollow space 12 between them. In the embodiment shown, the selvedges 8 , 10 run parallel to one another, so that the cavity 12 has the same width over its entire length. figure 2 and 3 The webbing is shown in its unturned state after fabrication; and figure 1 The webbing in is ready for use and will be figure 2 The webbing shown is turned over so that the selvedges 8, 10 are no longer exposed but located inside.

[0026] Such as image 3 As shown, the webbing is woven from warp yarns 14 which are connected to each other by weft yarns 16 . Warp yarn 14 at cavity 12 1 Best warp 14 than selvage 8, 10 2 Has a thicker wire diameter. All warp threads run parallel to each other, with warp thread 14 at selvedges 8, 10 2 Than the warp yarns 14 of the fabric layers 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com