Car light close-range photogrammetry method

A measurement method and technology of close-up photography, applied in the direction of photo interpretation, etc., can solve the problems of inability to realize photogrammetry process, difficulty in rapid, high-precision measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

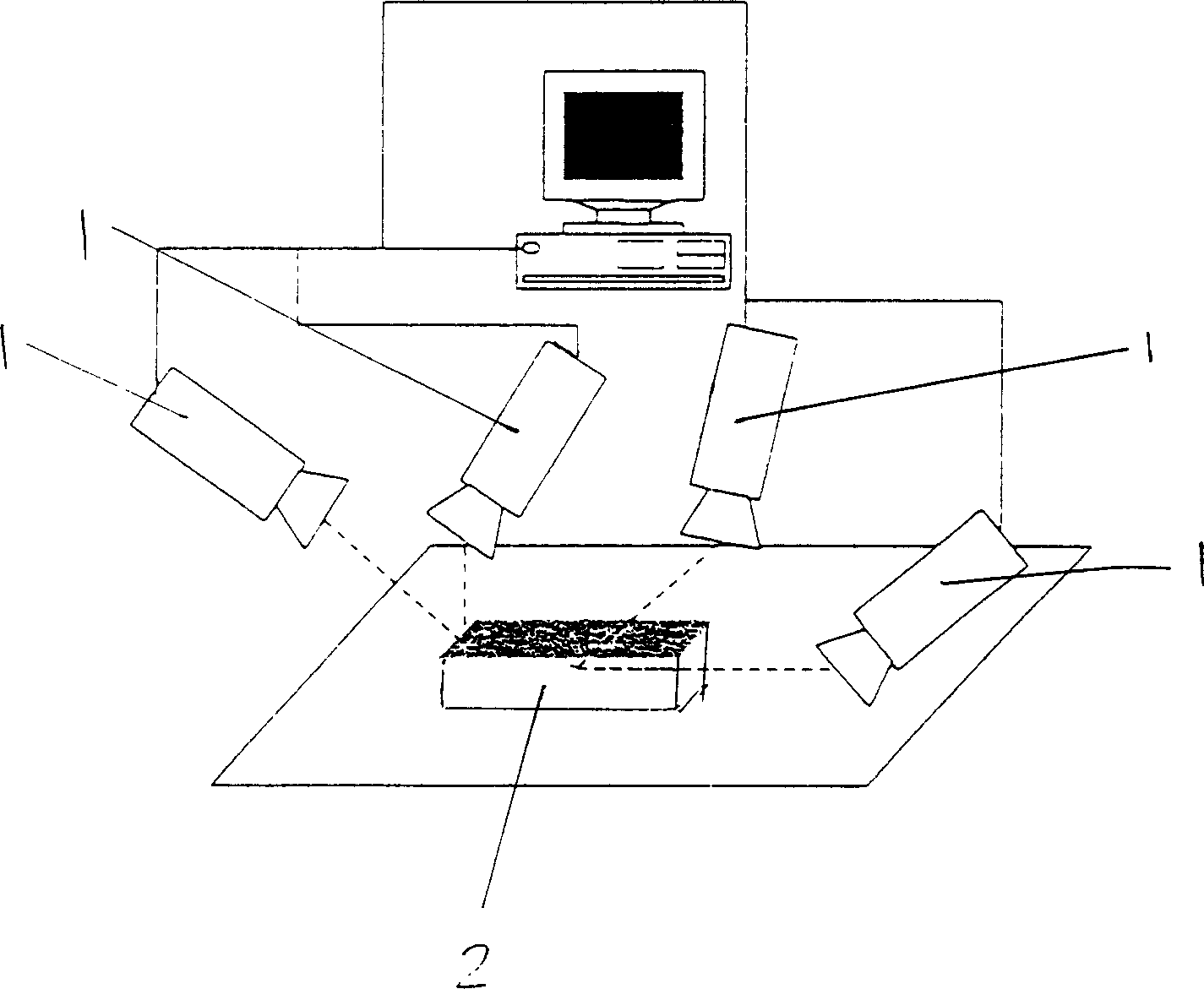

[0006] In the figure, four photographic devices 1 placed in pairs perpendicular to each other are arranged. This is because the adjacent points cannot be distinguished on the image, but when the angle between the edge line and the photographic baseline is greater than 45 degrees and the measurement point is in the vertical It can be distinguished in the spatial plane of the edge, and every two perpendicular to each other is a group. After shooting, only the measurement points with an angle greater than 45 degrees are processed, that is, there is only one group of left and right images for a certain point. The photographic baselines of the two groups of photographic devices 1 are perpendicular to each other, and each group of photographic devices 1 is used to measure the measurement point 3 on the edge of the car light 2 when the angle between the two groups of photographic devices 1 is relatively large; The four images of the four images are recorded as the first group of left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com