Shock absorber with frequency-dependent damping

A shock absorber and flow resistance technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as narrow passages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

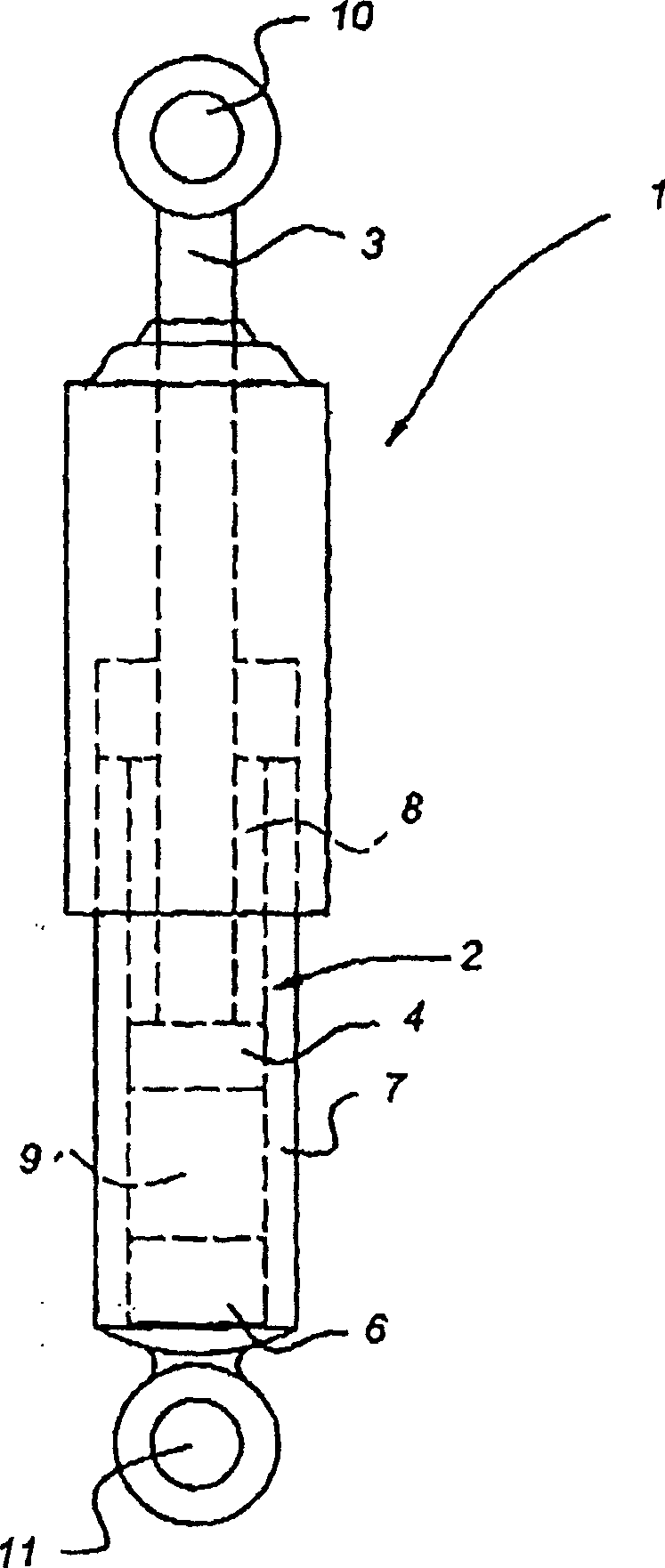

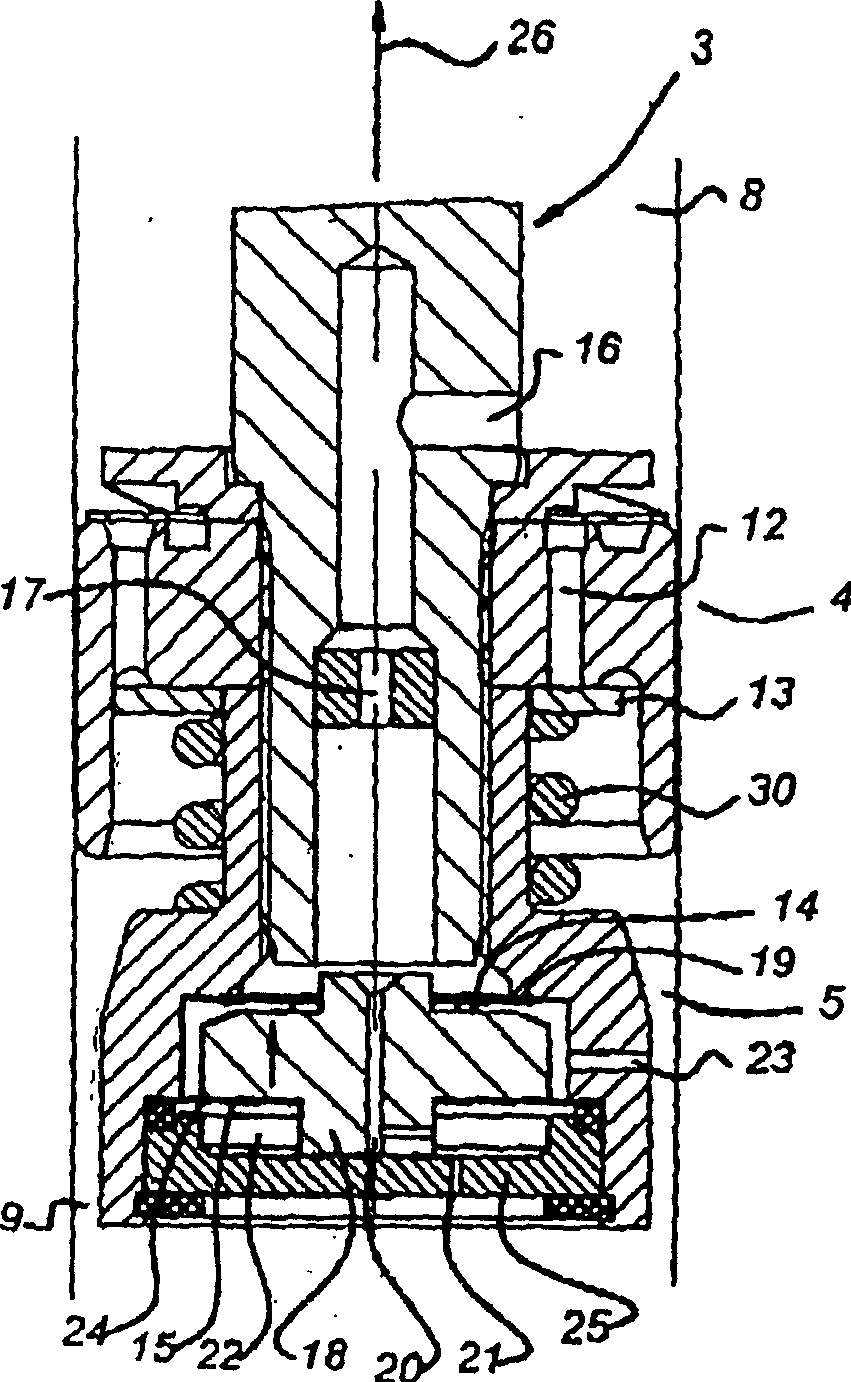

[0033] figure 1 , the shock absorber is generally indicated by reference numeral 1 . The shock absorber comprises a cylinder part 2 and a piston part 3 . The piston part 3 contains a piston 4 which delimits two oppositely positioned cavities within the cylinder part. Reference numeral 8 designates a first cavity and reference numeral 9 designates a second cavity. Via the eyelet 10, the piston part 3 can be fixed, for example, to the fuselage of a vehicle. Eyelets 11 are used, for example, for fastening to a part of a suspension system of a vehicle. The shock absorber shown here is of the type in which the cylinder part 2 contains an annular channel 7 for storing shock absorber fluid and also has a bottom valve 6 connecting the second chamber 9 to the fluid storage chamber 7 . It should be understood that the present invention can be applied to any type of shock absorber, with or without an external reservoir, which can be made in some manner known in the art.

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com