Page rotating method of printing operation

A technology for printing jobs and jobs, applied in the direction of digital output to printing units, instruments, optics, etc., can solve the problems of inconvenient use, unacceptable speed, unacceptable special chip methods, etc., to avoid time-consuming operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

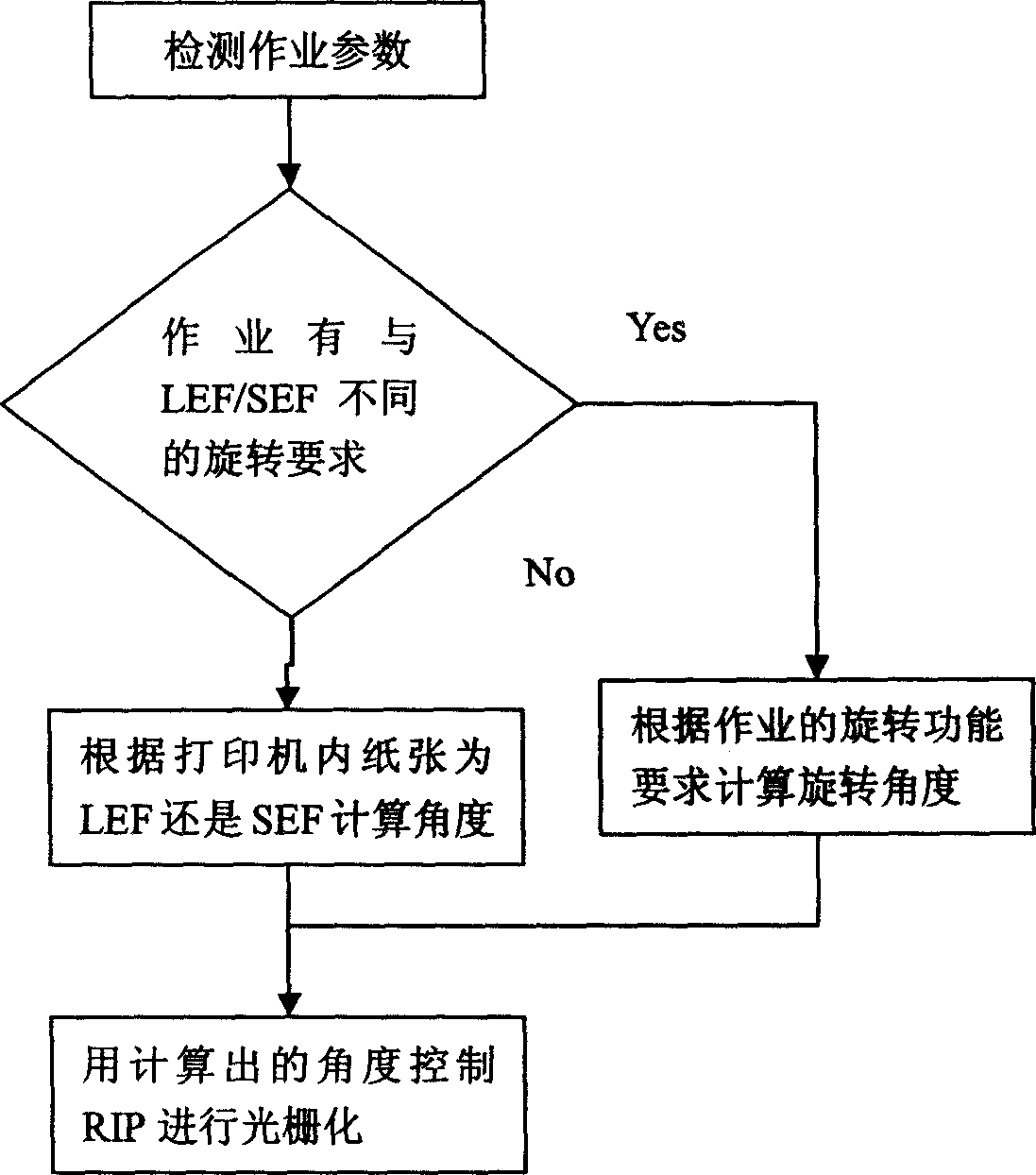

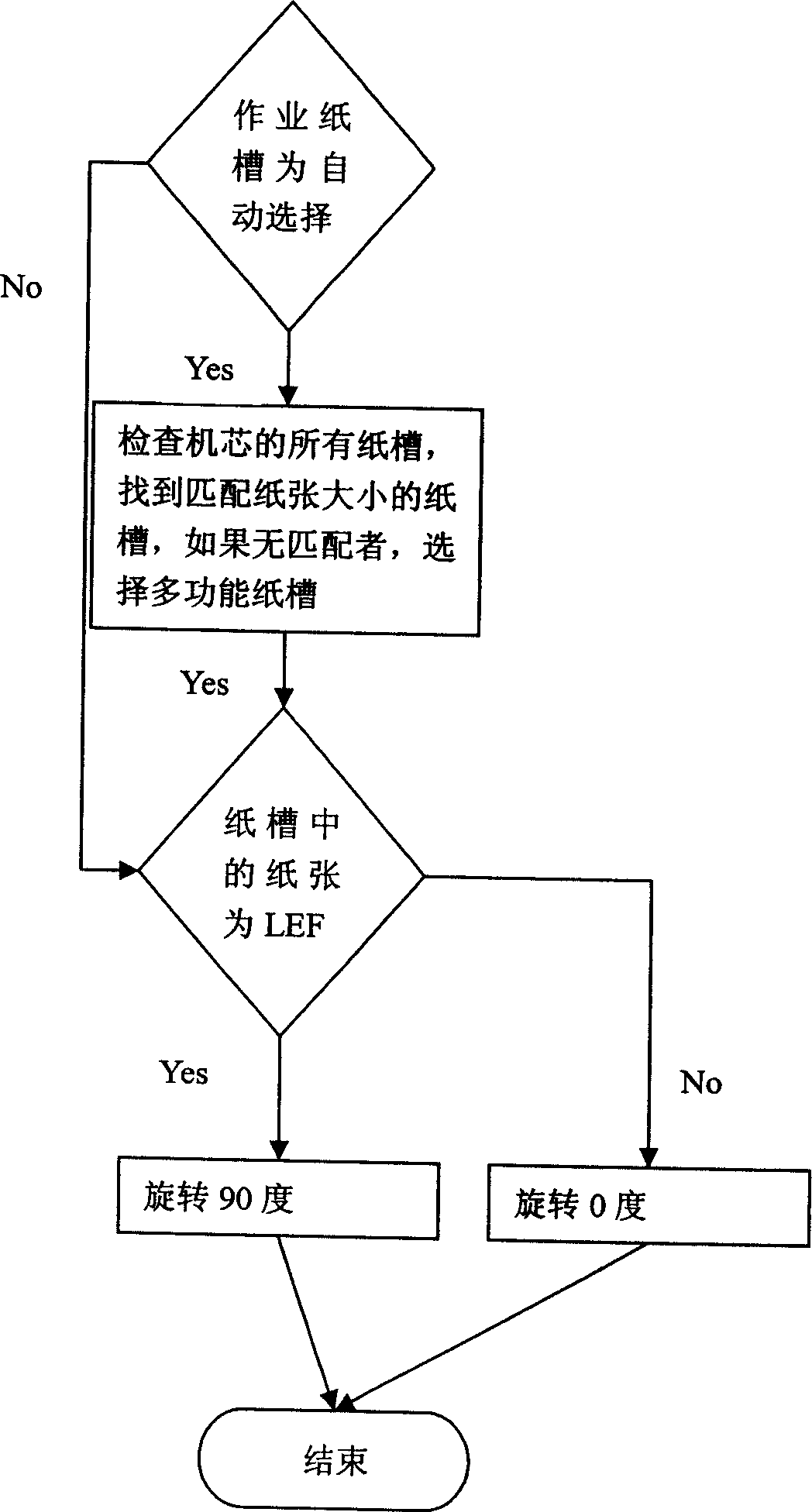

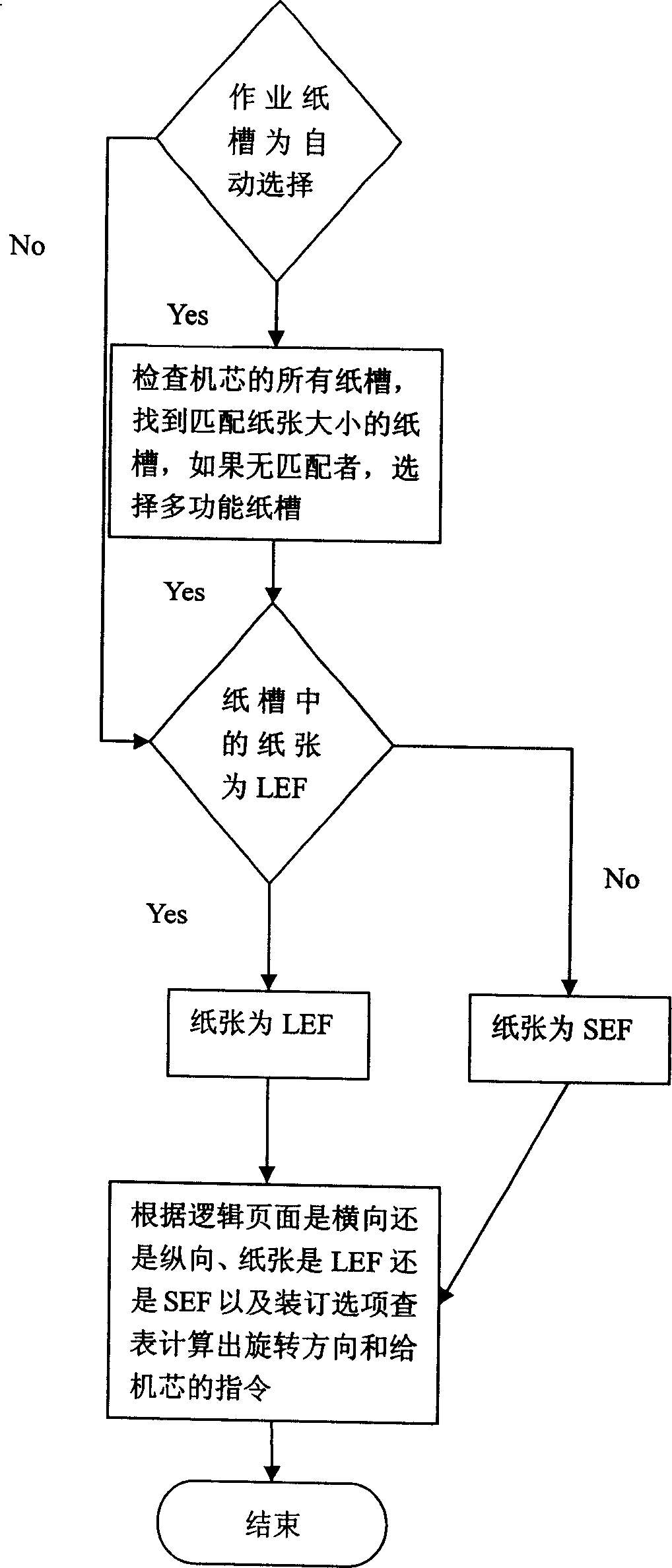

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment, but present embodiment is not in order to limit the present invention:

[0022] Such as Figure 5 The illustrated embodiment introduces the following components to realize the method of the present invention:

[0023] The front-end software 50 refers to an application program that supports printing on operating systems such as Windows or Macintosh, such as Word or PageMaker, etc.;

[0024] 51 refers to the rasterization module RIP;

[0025] The print manager 52 refers to a module that realizes the page rotation processing function of the present invention;

[0026] PPD53 refers to the Postscript printer description file, which describes the characteristics of the printer, such as the type of paper supported by the printer, whether the printer supports binding, etc.;

[0027] The core 54 refers to the device that transfers the dot matrix after RIP to the pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com