Regulatuble fastening mould cotton core shoping hub

A cotton core and button mold technology, applied in clothing, underwear, baby underwear, etc., can solve the problems of fixed mold cavity and inability to adjust the thickness of the cotton core, so as to achieve beautiful appearance, save waste suction fan and cutter assembly, and facilitate the the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

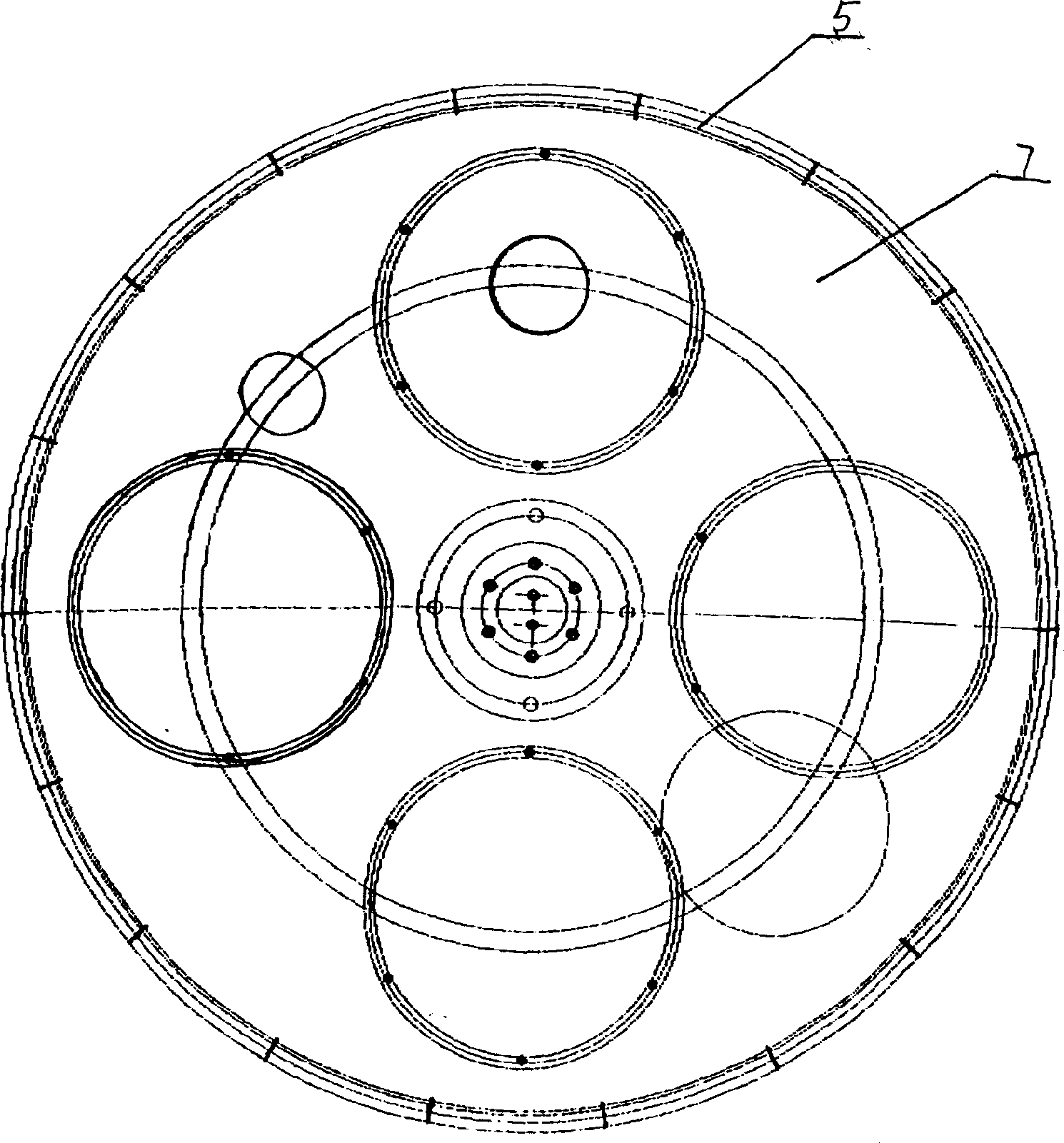

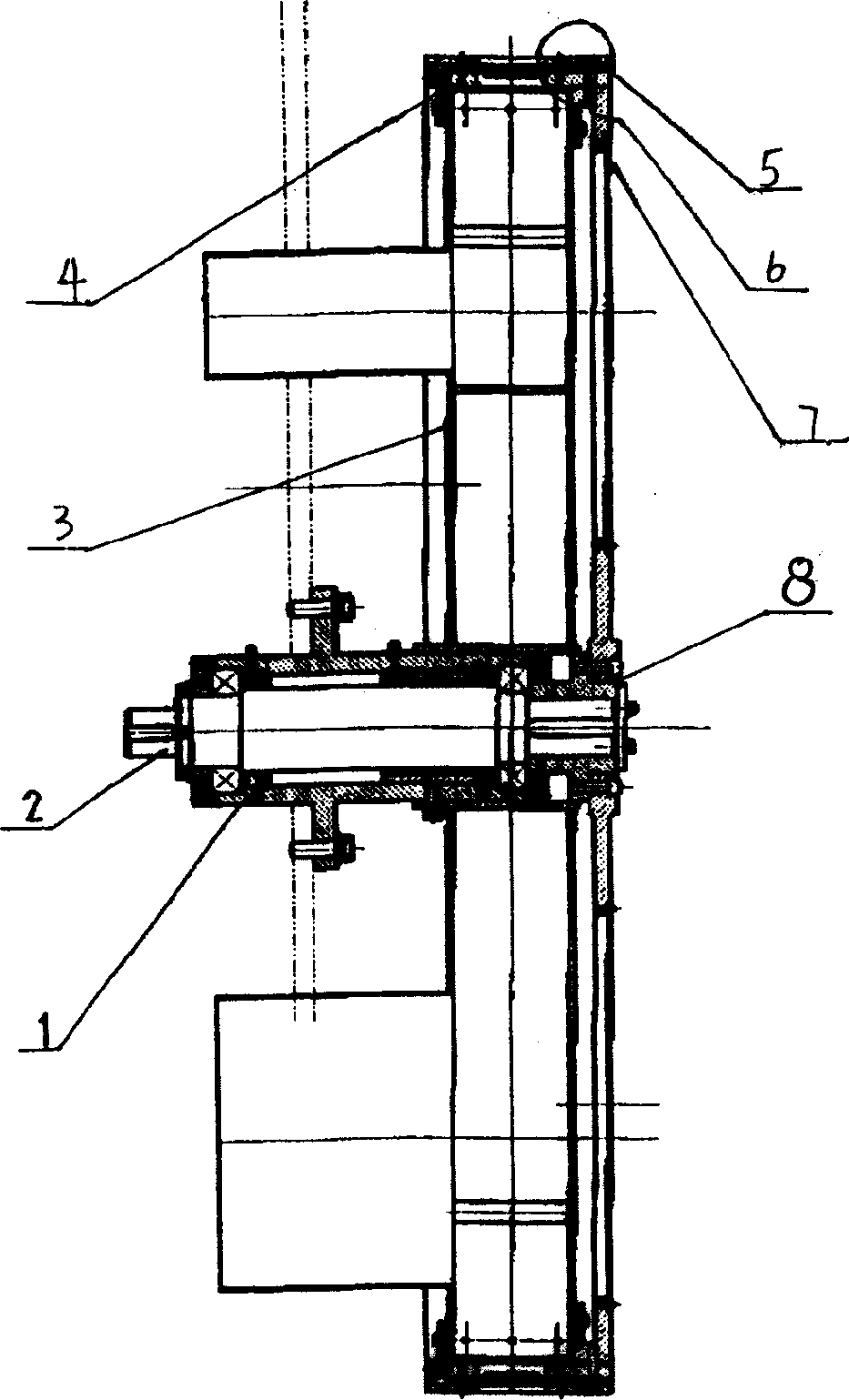

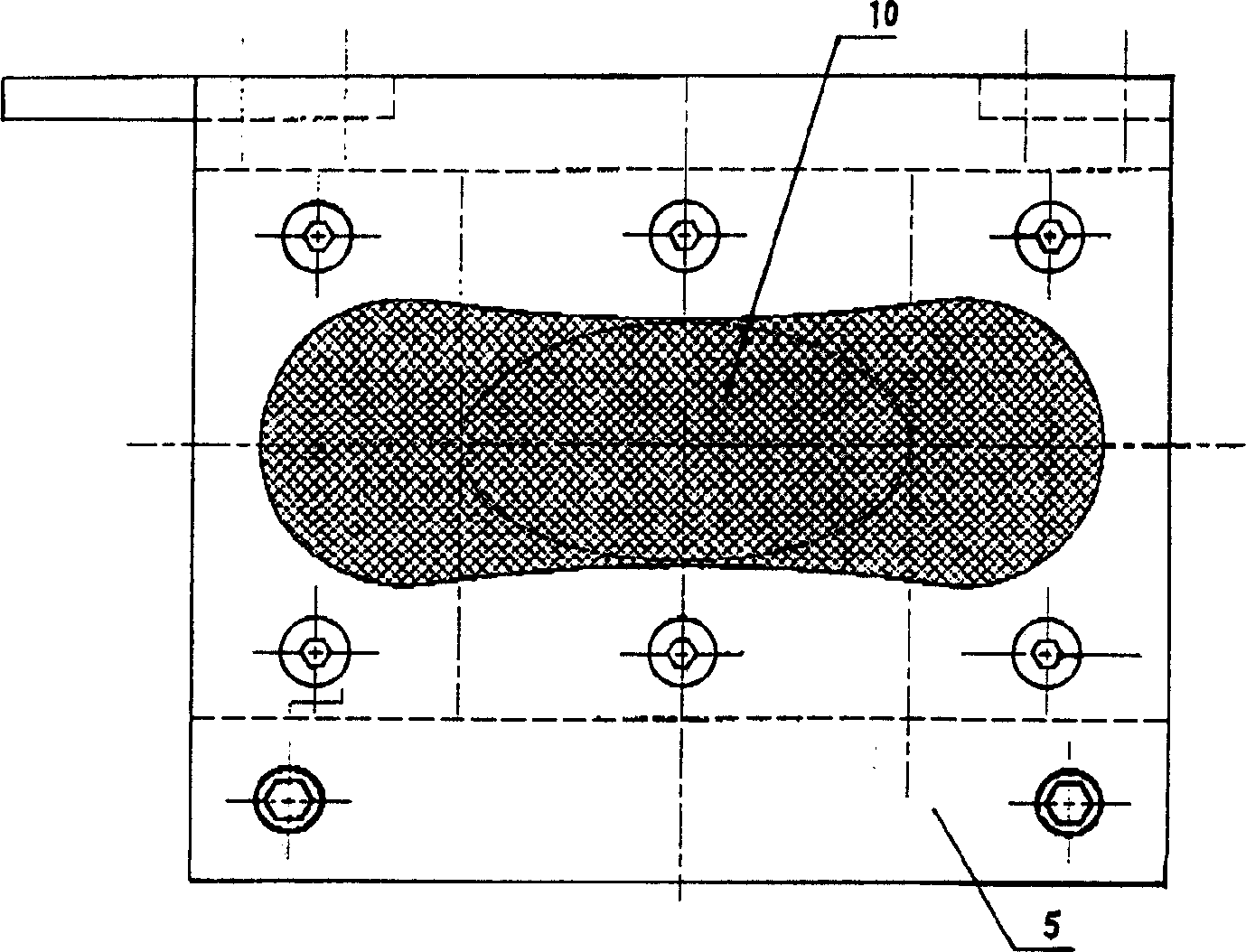

[0025] See figure 1 , figure 2 , The adjustable buckle mold cotton core forming hub includes a main shaft 2, a bearing seat 1, a negative pressure cylinder 3, a pressure ring 4, a tire mold module 5, a sealing ring 6, a turntable 7, a fixed disk 8 and a seal 9. The tire mold module 5 includes tire mold fixing tiles 12 , tire mold steel wire mesh 10 , tire mold pressing plate 14 and tire mold connecting plate 13 . Tire mold is fixed. 12 and the tire mold steel wire mesh 10 flange between tire mold pressure plate 14 are equipped with tire mold gasket 11, the middle part of the tire mold gasket is an opening, and the hole is connected with the middle part of the tire mold steel wire mesh. The groove corresponds to see in Image 6 , Figure 7 , Figure 8 and Figure 9 .

[0026] The tire mold spacer 11 is either installed on one side adjacent to the tire mold pressure plate 14, or installed on one side adjacent to the tire mold fixed tile 12.

[0027] When it is necessary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com