New type clothes interfacing and its manufacturing method

A garment and interlining technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve problems such as high cost, shortage of horsetail and yak tail supply, etc., and achieve good deformation recovery, superior performance, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structure and specific implementation of a new garment interlining of the present invention will be further described below in conjunction with the accompanying drawings.

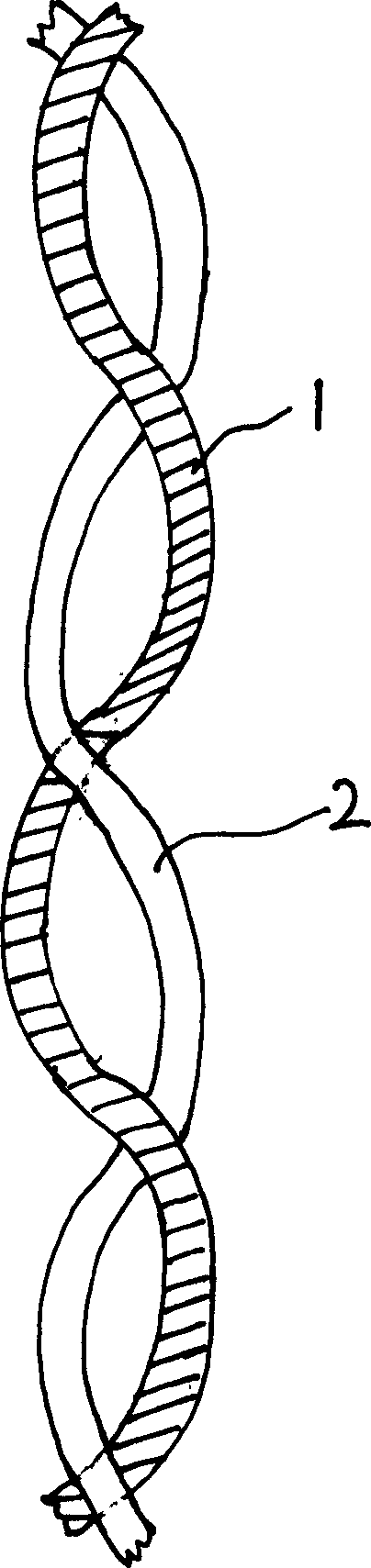

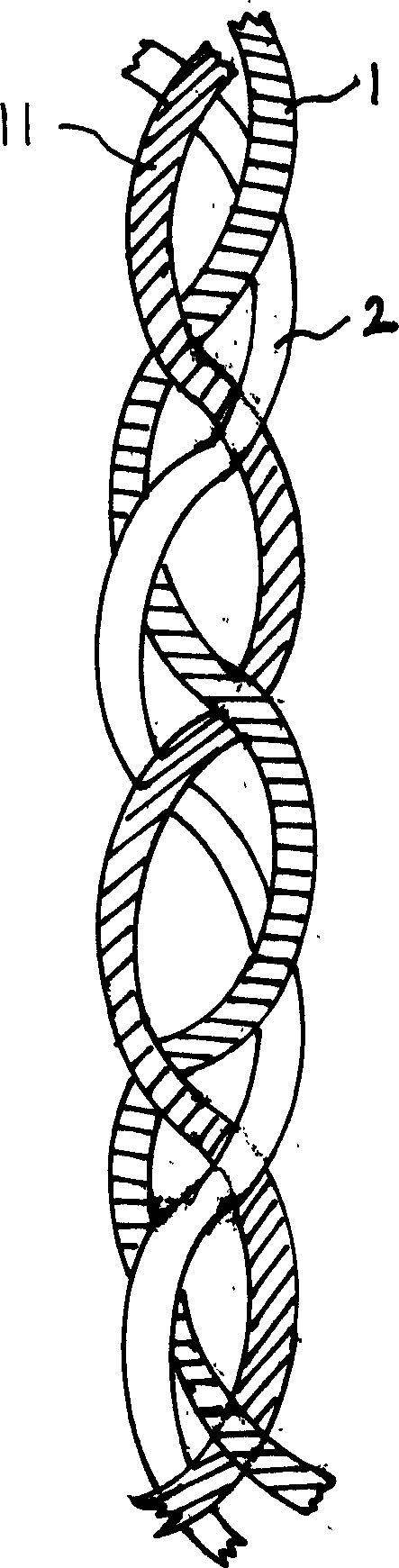

[0011] A novel clothing interlining cloth of the present invention is woven from warp yarns and weft yarns, wherein the warp yarns are made of cotton yarns, and the weft yarns are interwoven from cotton yarns and polyester filaments, and the structure of the weft yarns interwoven by cotton yarns and polyester filaments can be as follows figure 1 A cotton yarn 1 and a polyester filament 2 are interweaved in forward and reverse directions or in the same direction as shown; it can also be as figure 2 The shown two cotton yarns 1, 11 and a polyester filament 2 interweave in the same direction or in the same direction; it is also possible to adopt the structure in which three cotton yarns and a polyester filament are interwoven in the same direction or in the same direction (Fig. not shown in

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com