Counter-rotary axial fan with adjustable inlet guide vanes

A technology of imported guide vanes and axial flow fans, applied in axial flow pumps, mechanical equipment, machines/engines, etc., can solve the problems of inconvenient adjustment of the flow-pressure performance curve, achieve high adjustment efficiency, simple adjustment structure, and easy adjustment wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure and working principle of the present invention will be described in detail below with reference to the accompanying drawings.

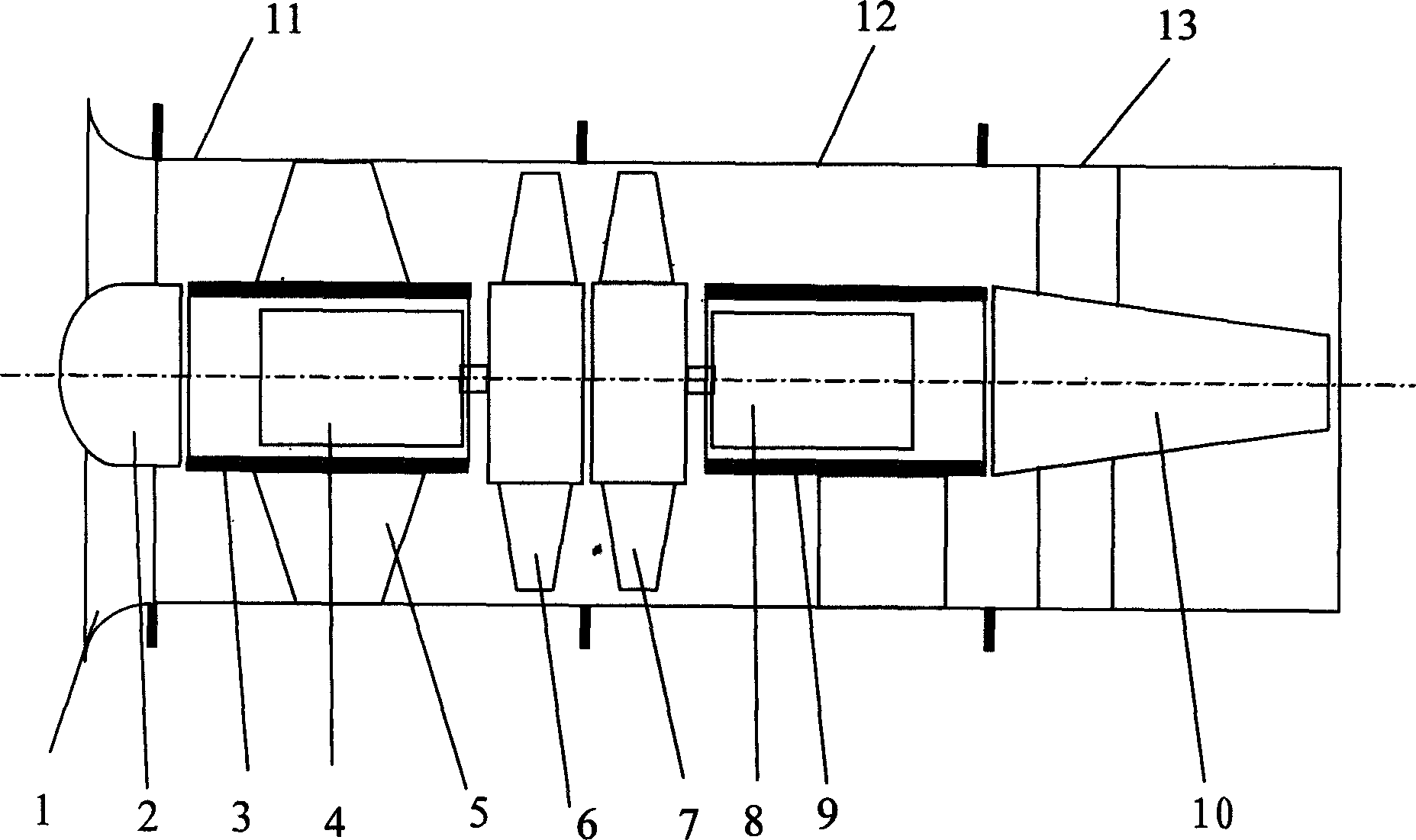

[0014] See figure 1 , A counter-rotating axial flow fan with adjustable inlet guide vanes, including an air collector 1, which is connected to the first-stage fan outer cylinder 11, the second-stage fan outer cylinder 12 and the diffuser 13 in sequence, and the air collector 1In the shell composed of the first-stage fan outer cylinder 11, the second-stage fan outer cylinder 12 and the diffuser cylinder 13, the first-stage motor 4, the first-stage bucket 6, the second-stage bucket 7 and the second-stage motor 8 are arranged in sequence, the first-stage motor 4 and the second-stage motor 8 are supported by the first-stage fan inner cylinder 3 and the second-stage fan inner cylinder 9 respectively. The first-stage fan inner cylinder 3 is connected to the fairing 2, and the second-stage fan The inner cylinder 9 is connected to the rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com