Mount

A technology of backing paper and edge paper, which is applied in the direction of paper, papermaking, special paper, etc., can solve the problem of uneven appearance of wallpaper, and achieve the effect of simplifying pasting work and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

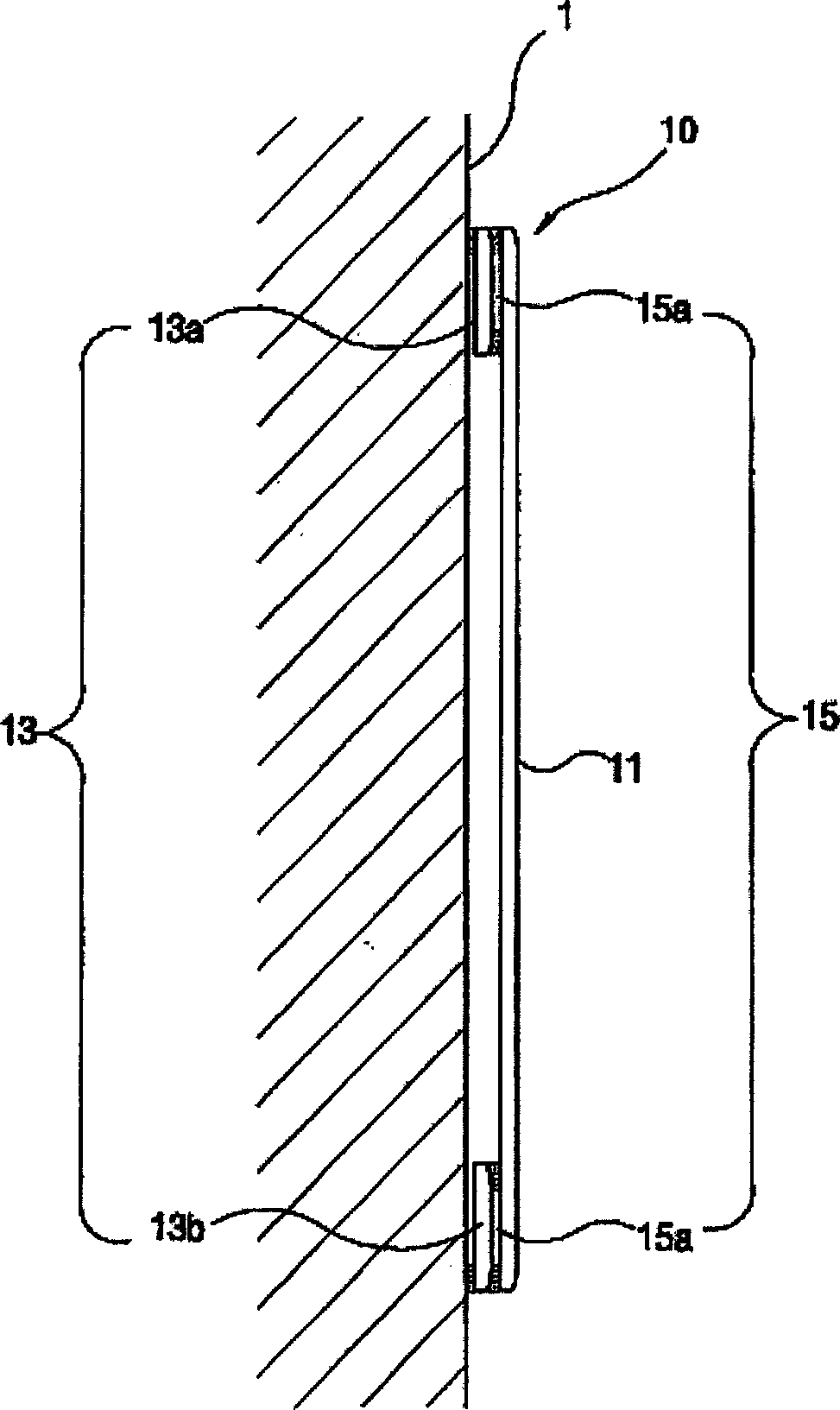

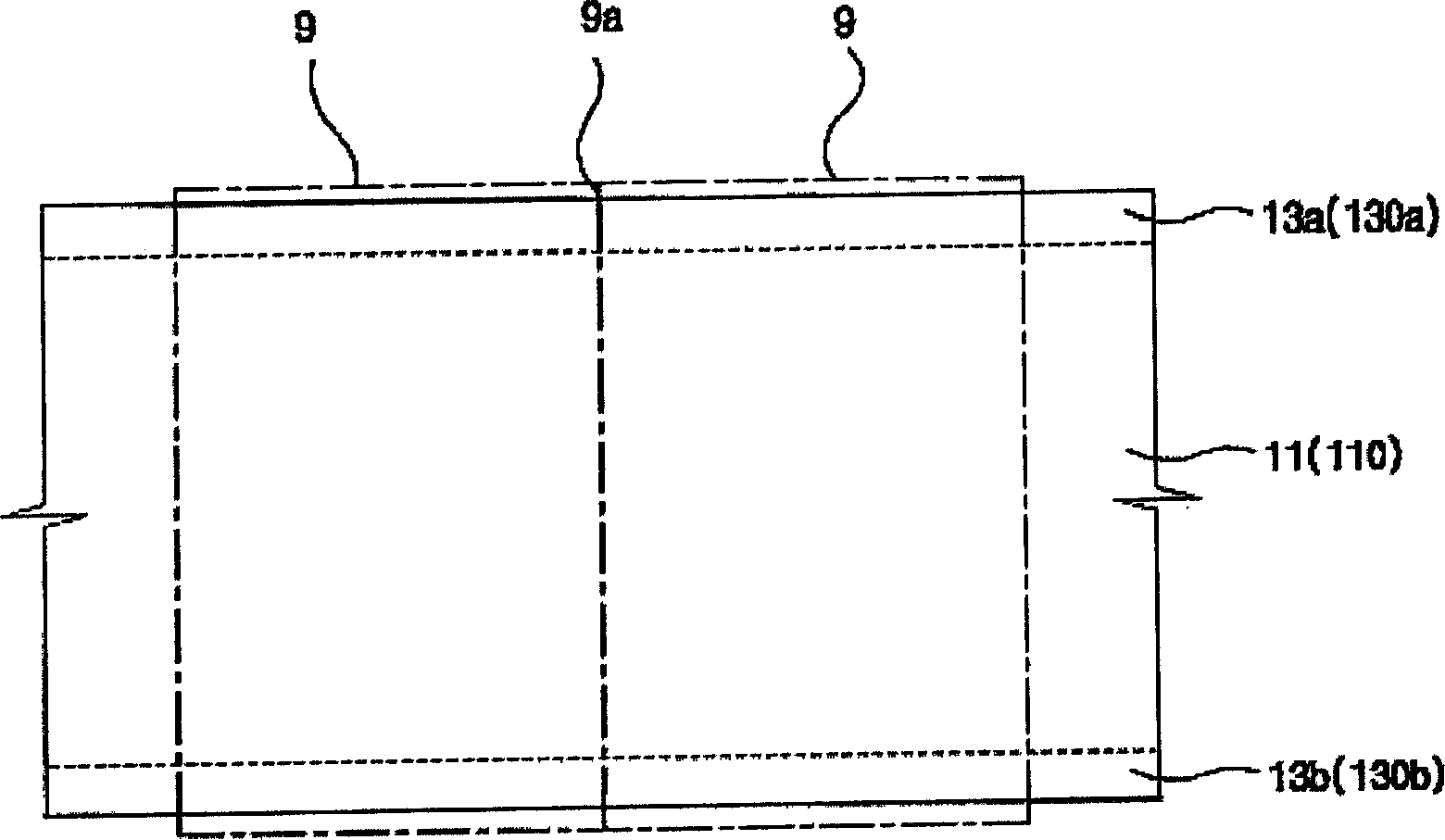

[0021] figure 1 It is an enlarged cross-sectional view showing a state in which the backing paper is first pasted according to the first embodiment of the present invention. The backing paper ( 10 ) according to the first embodiment is generally composed of synthetic paper ( 11 ) and edge paper ( 13 a ) ( 13 b ) stacked on the upper and lower ends of the synthetic paper ( 11 ).

[0022] The synthetic paper (11) is made of a material mixed with pulp and synthetic resin (especially polyester fiber). The synthetic paper (11) of this material not only has large resistance to shrinkage during the drying process of the pasted wallpaper (9), but also has the properties of paper, so there is no need for edge paper (7).

[0023] In addition, the synthetic paper (11) has the properties of paper, and the edge paper (13a) (13b) is easily stacked on the upper and lower sides of the synthetic paper (11). Therefore, can use the backing paper (10) that synthetic paper (11) and edge paper (...

Embodiment 2

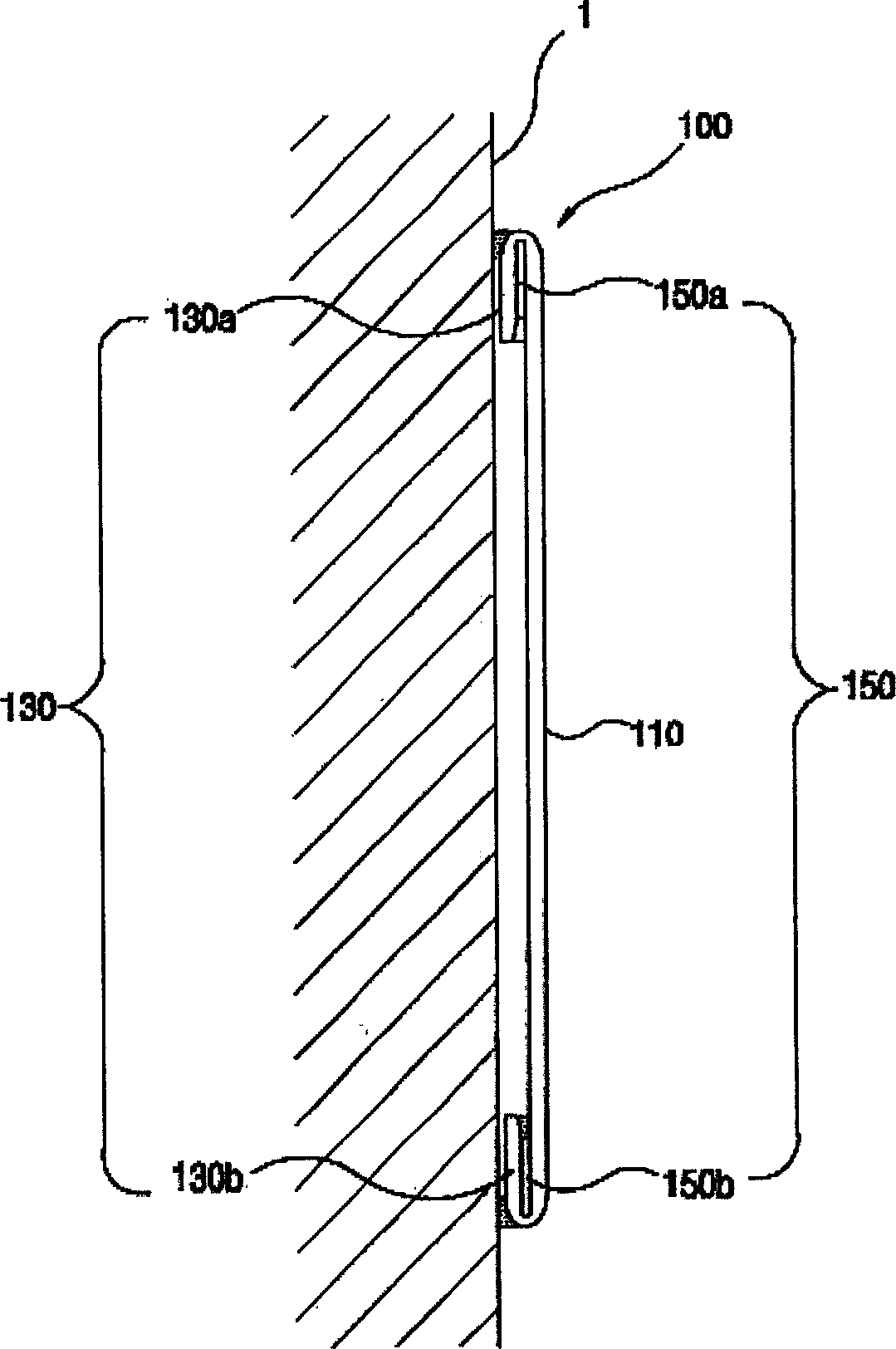

[0029] In the backing paper (10) of embodiment one, edge paper (13a) (13b) is pasted on one side of the upper and lower end parts of synthetic paper (11). The backing paper (100) of the second embodiment does not use additional side paper, and combines the structure of the side paper (130) formed by folding the upper and lower ends of the synthetic paper (11), thus simplifying the manufacture of the backing paper process.

[0030] figure 2 It is an enlarged cross-sectional view showing a state in which the backing paper is pasted for the first time according to the second embodiment of the present invention. The backing paper (100) of the present embodiment 2 is similar in structure and function to the backing paper (10) of the first embodiment, but these two kinds of edge papers (130) are the edges that fold the upper end of the synthetic paper (110) The composition of the paper (130a) and the side paper (130b) formed by folding the lower end of the synthetic paper (110) d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com