High speed interlayer shearing crusher for nano powder

A nano-powder and crusher technology, which is applied in grain processing and other fields, can solve problems such as the difficulty of crushing micron-sized solid particles, and achieve the effects of solving severe wear, excessive noise, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

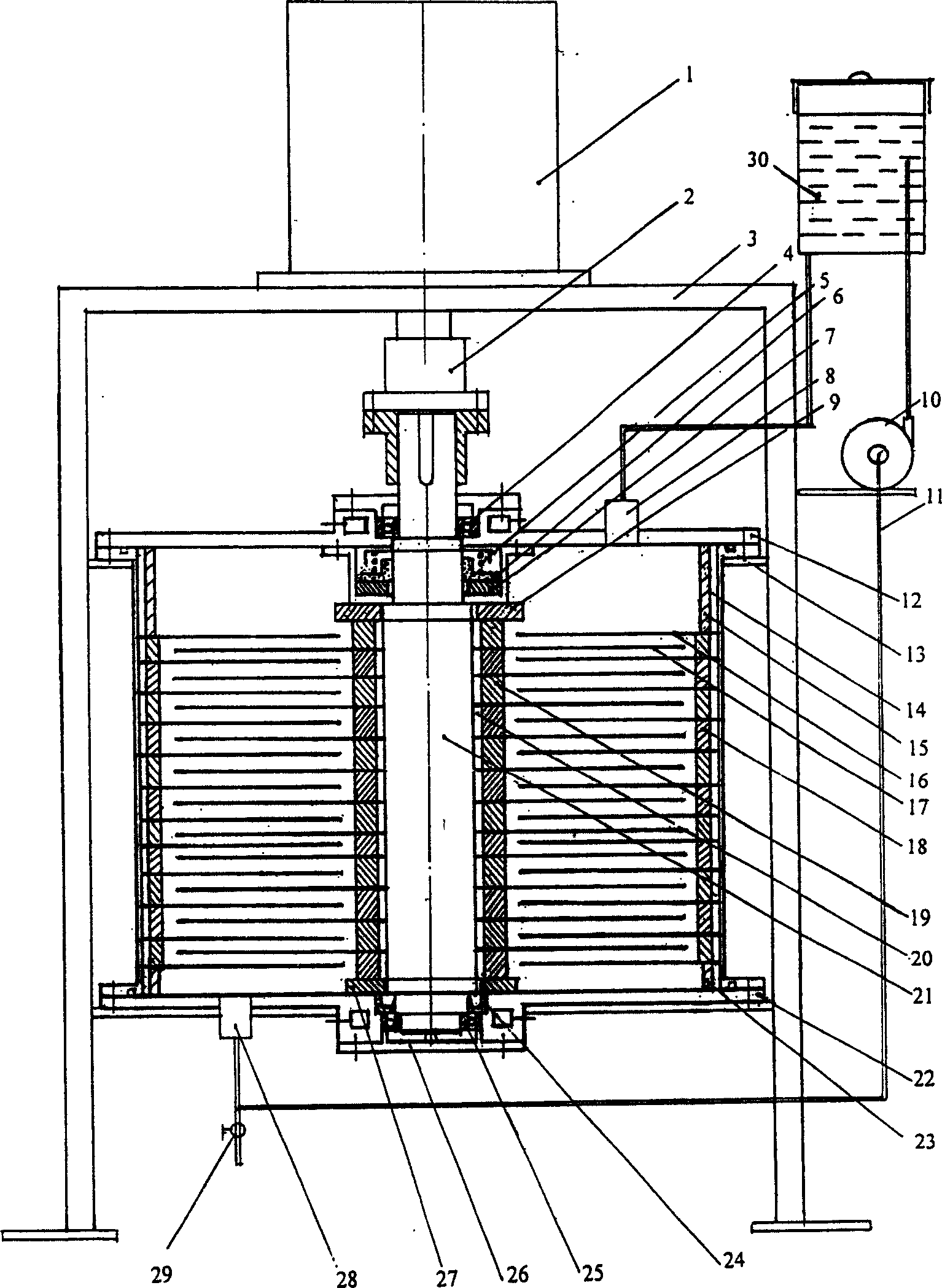

[0030] Embodiment 1 and effect see figure 1 .

[0031] When preparing a high-speed interlayer shear crusher with a nominal volume of 346ml, it should be designed according to the following

[0032] 1. Preparation of the main cylinder of the shearing crusher

[0033] a. First make a stainless steel cylinder with an inner diameter of φ70mm and a height of 90mm, with a wall thickness of 5mm, openings at both ends, welded with a stainless steel flange with a sealing groove, and form the main cylinder part 13.

[0034] b. Upper and lower end caps ( figure 1 Middle, 12, 22) are to make with the stainless steel plate of thickness 8mm. A water-cooling sleeve is welded at the center of the upper and lower end covers to cool the bearings. The lower end of the upper end cover is fixed to the lower part of the center hole of the upper end cover by means of screw connection, and the shaft seal at the lower end is fixed above the lower bearing for protection. lower bearing.

[0035] 2,...

Embodiment 2

[0049] Embodiment 2 and effect:

[0050] When preparing a high-speed interlayer shear crusher with a nominal volume of 6848ml, it should be designed according to the following:

[0051] 1. Preparation of the main body of the shearing crusher....

[0052] a. First make a stainless steel cylinder with an inner diameter of φ200mm and a height of 218mm, with a wall thickness of 6mm, openings at both ends, welded with a stainless steel flange with a sealing groove, and form the main cylinder part 13. Add a layer of interlayer water jacket with thickness δ=10mm.

[0053] b. Upper and lower end caps ( figure 1 Middle, 12, 22) are to make with the stainless steel plate of thickness 12mm. Water-cooling sleeves are welded at the center of the upper and lower end covers to cool the bearings. The lower end of the upper end cover is fixed to the lower part of the central hole of the upper end cover by means of screw connection. The shaft seal at the lower end is fixed above the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com