Multifunctional thresher

A threshing machine, multi-functional technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of high cost, high processing and manufacturing costs, complex transmission bearings, etc., and achieve the effect of reducing cost and simplifying the blade part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

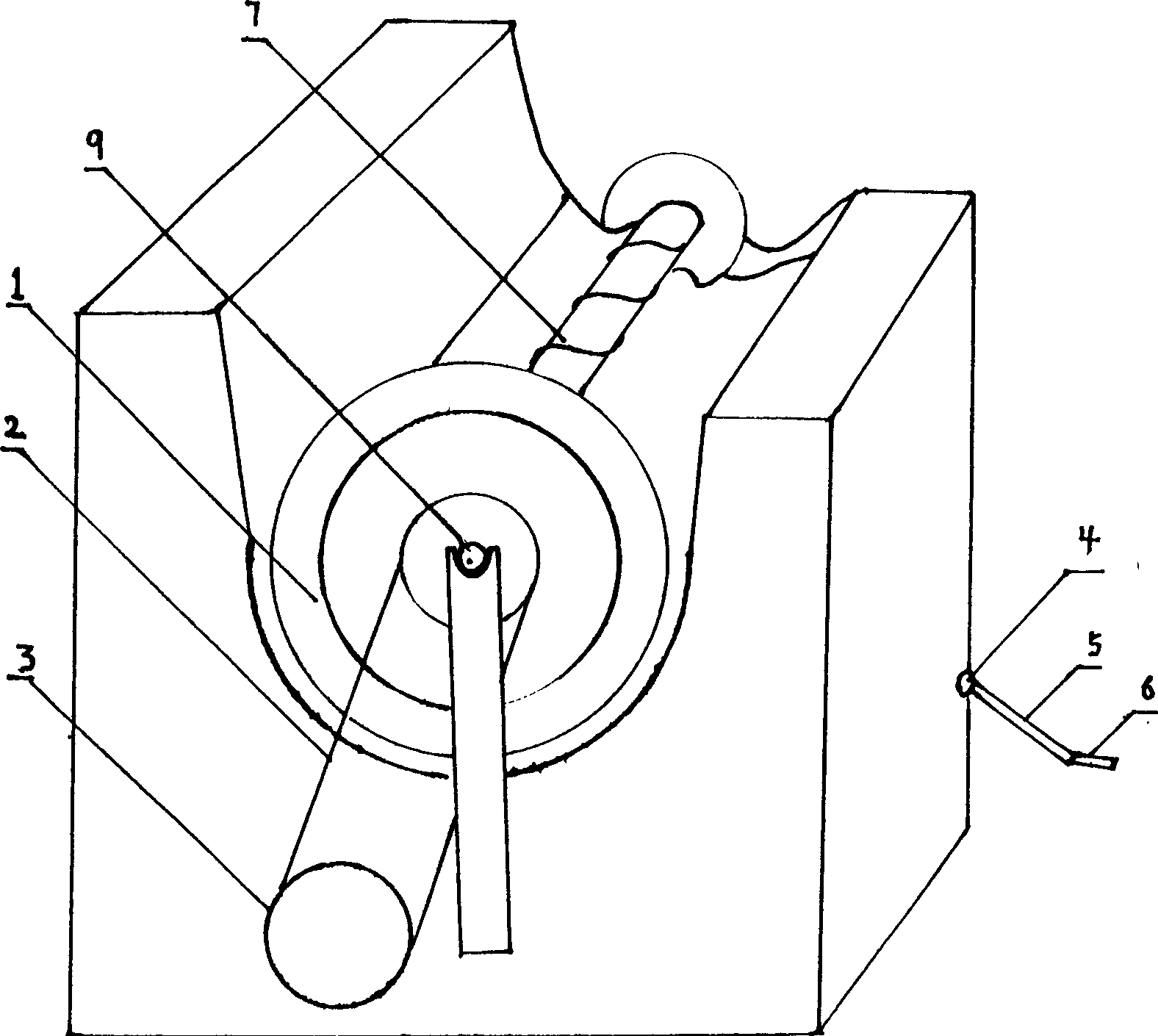

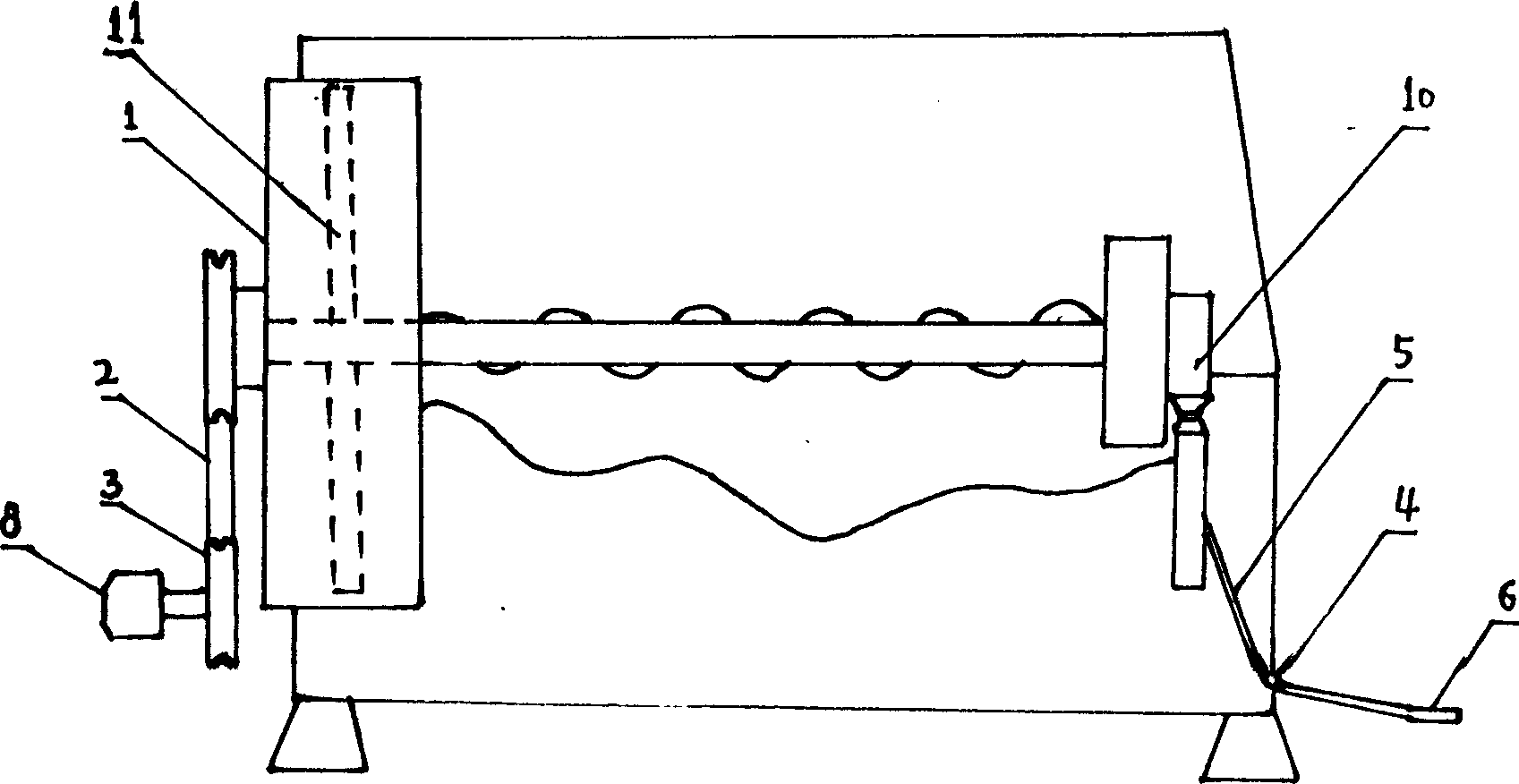

Embodiment 1

[0013] A multifunctional thresher, which consists of a fuselage, a blower wheel 1, an electric transmission system, a foot-driven transmission system, and a threshing auger 7. The electric transmission system includes an electric transmission gear, a belt 2, a pulley 3, and a motor 8; The transmission system includes a fulcrum 4, a transmission rod 5, a pedal 6, and a foot-operated transmission gear 10; the blower wheel 1 is arranged on one side of the fuselage, and is connected with the threshing auger 7, and the motor 8 is also arranged on the same side of the fuselage. The motor 8 drives the pulley 3, and the pulley 3 is connected with the electric transmission gear arranged on the outside of the blower wheel 1 through the belt 2; the other side of the fuselage is provided with a foot-driven transmission system, and the middle part of the transmission rod 5 is positioned on the fulcrum 4 set on the fuselage Above, the pedal 6 is connected with one end of the transmission rod...

Embodiment 2

[0015] The electric transmission gear is connected with the threshing auger 7 by using the outer fork bearing 9; the rest are the same as in Embodiment 1.

[0016] The fuselage of the present invention can be made of cheap wood or iron, further reducing the cost.

[0017] When the present invention needs electric high-efficiency wind and grain during use, the foot-driven transmission gear 10 of the foot-driven transmission system can be removed first, so that the power source is provided by the motor 8, and the foot-driven transmission system does not work, and it will not affect the electric motor. The work of transmission system, motor 8 drives outer fork bearing 9 through belt pulley 3, belt 2, blower 1 rotates and provides wind power, simultaneously threshing auger 7 also rotates work, finishes normal threshing.

[0018] In the occasion that there is no power supply or the amount of wind crops is small, the belt 2 of the electric transmission system is pulled down, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com