Millstone for fiberizer

A refiner and grinding disc technology, which is applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc. Length, reduced fiber loss, noise cancellation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

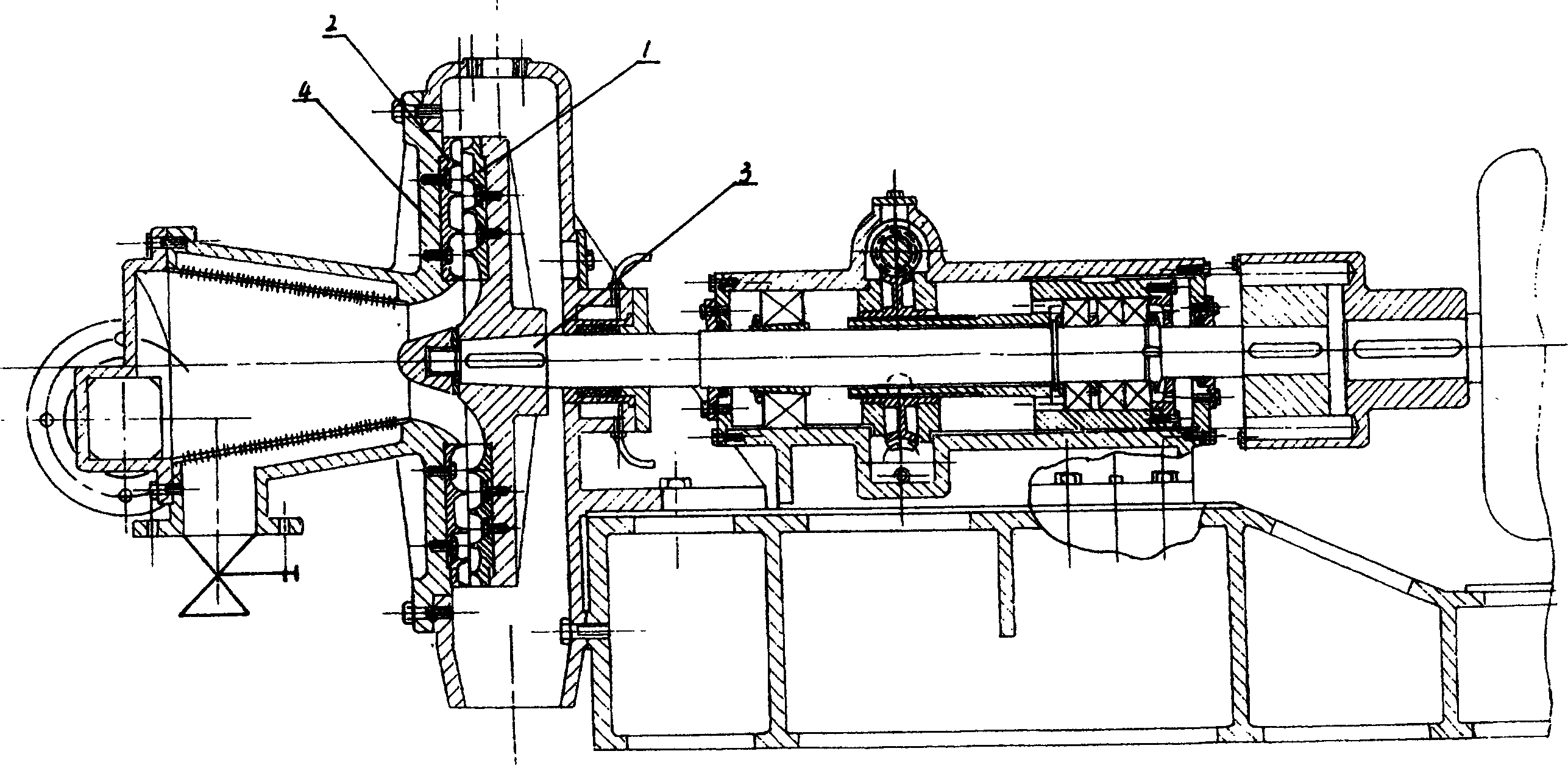

[0020] Such as figure 1 As shown, a grinding disc for a refiner of the present invention includes a rotating grinding disc 1 mounted on the main shaft 3 of the refiner and a fixed grinding disc mounted on the refiner housing 4 and matched with the rotating grinding disc 1 2.

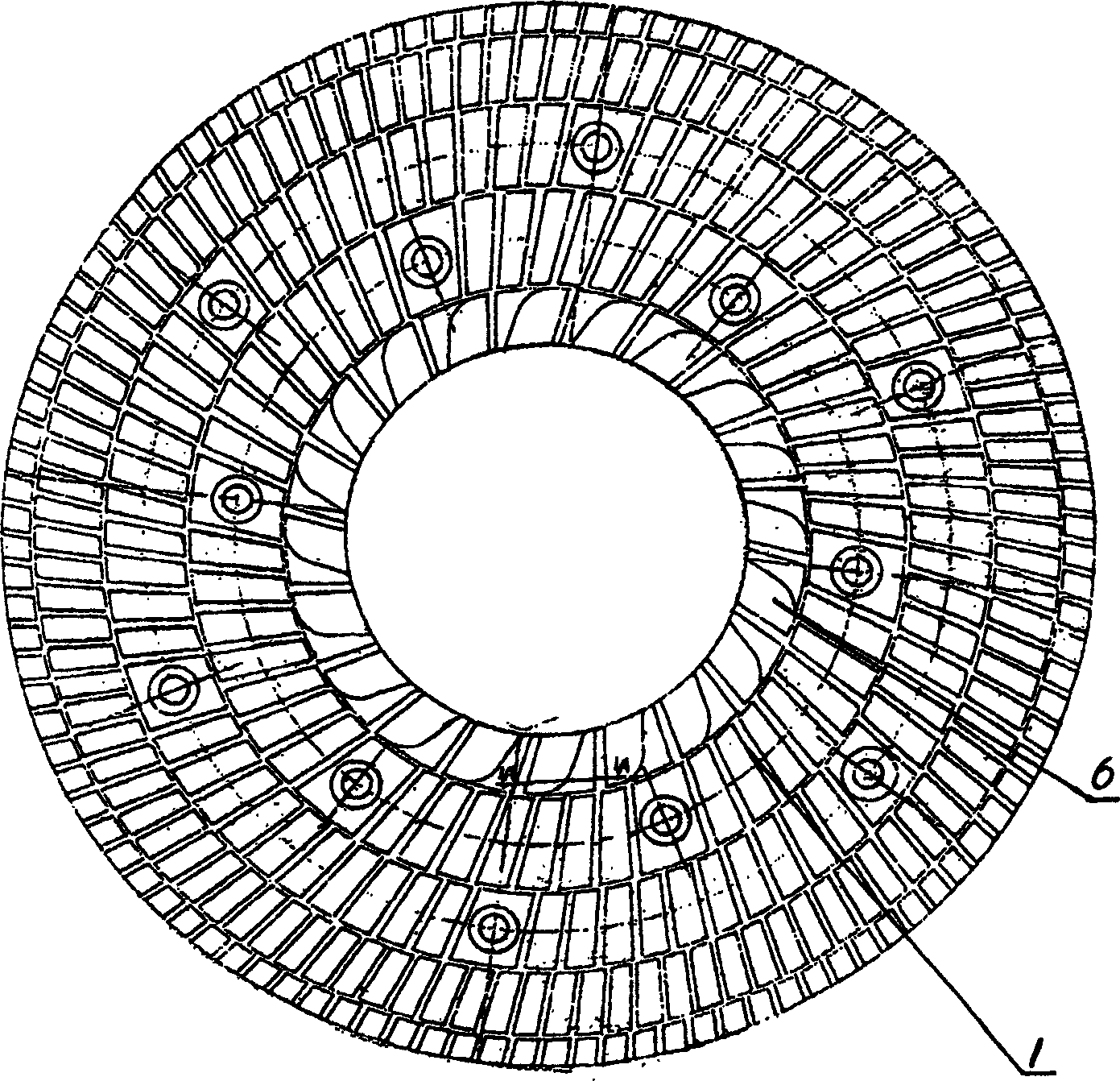

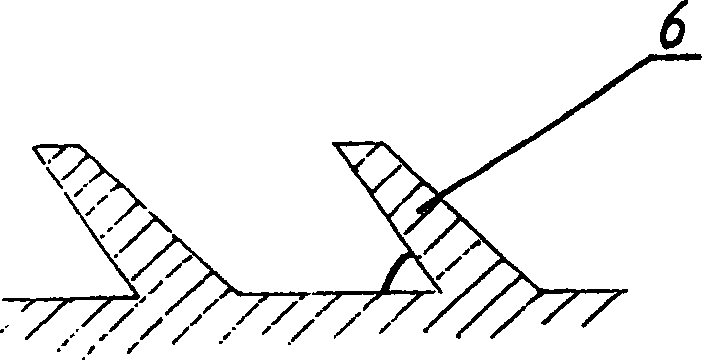

[0021] Such as Figure 2-6 As shown, the tooth surfaces of the rotating grinding disc 1 and the fixed grinding disc 2 are provided with concentric circular retaining dams 5, 7, and every two concentric circular retaining dams 5, 7 are a section, and each grinding disc is provided with 3 or 3 For the above concentric circle intervals, the width of the interval gradually decreases with the increase of the radius, and the tooth depth of the grinding teeth also gradually decreases with the increase of the radius; form an acute angle of inclination.

[0022] The working surface of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com