Preparation process of high producing rate, energy-saving water coal paste

A coal-water slurry and high-yield technology, which is applied in the direction of combustion methods, block/powder fuel preparation, and combustion equipment, can solve the problems of high energy consumption and low yield, and achieve the reduction of power consumption per ton of pulp and high yield High, strong grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

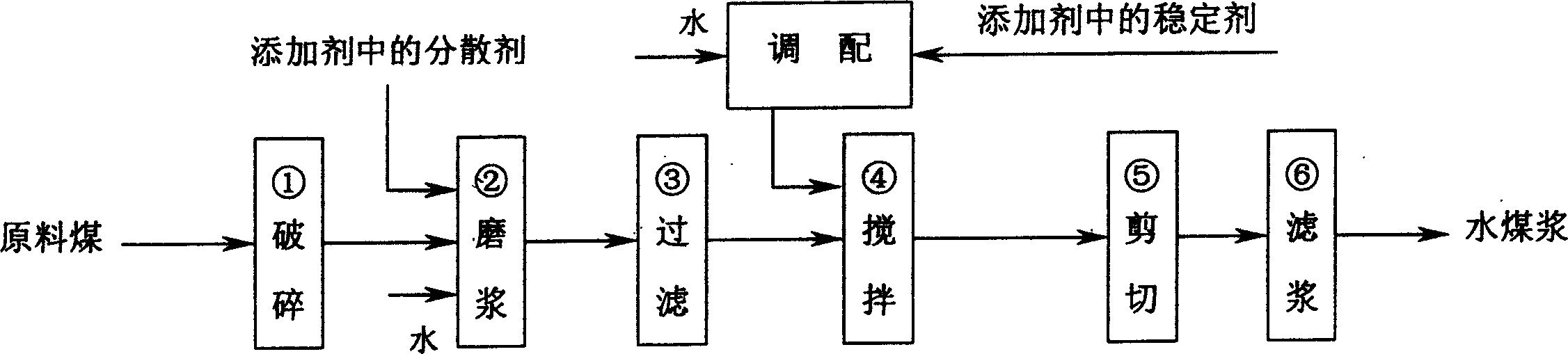

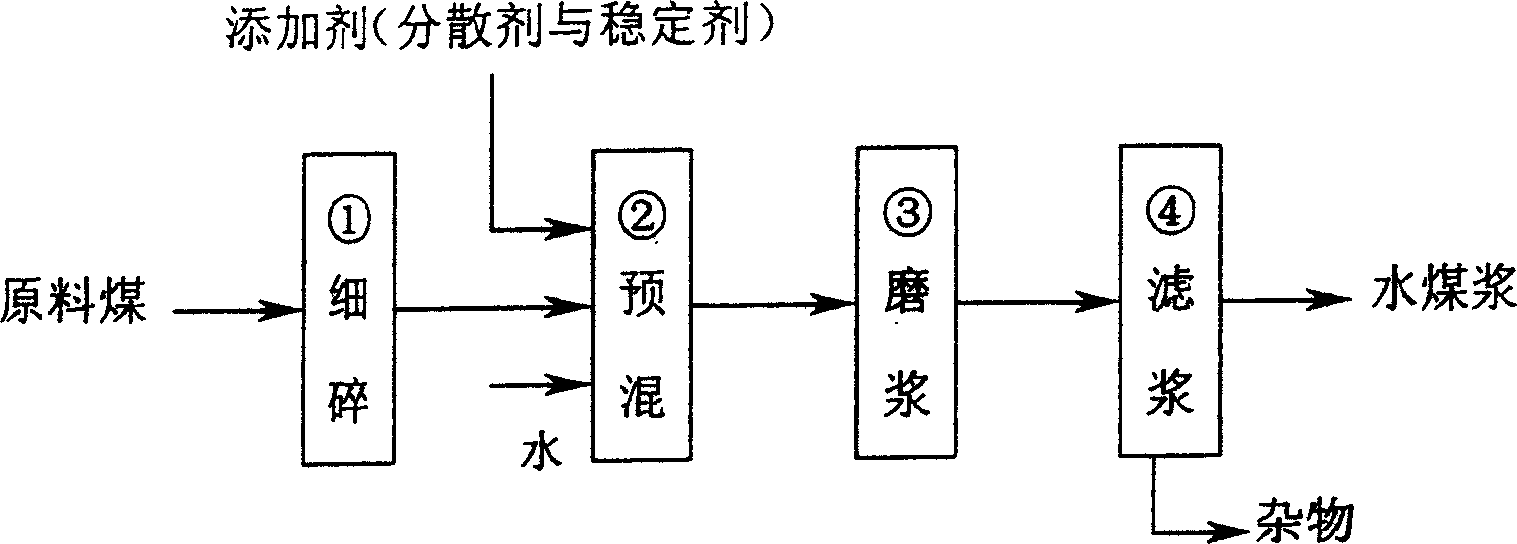

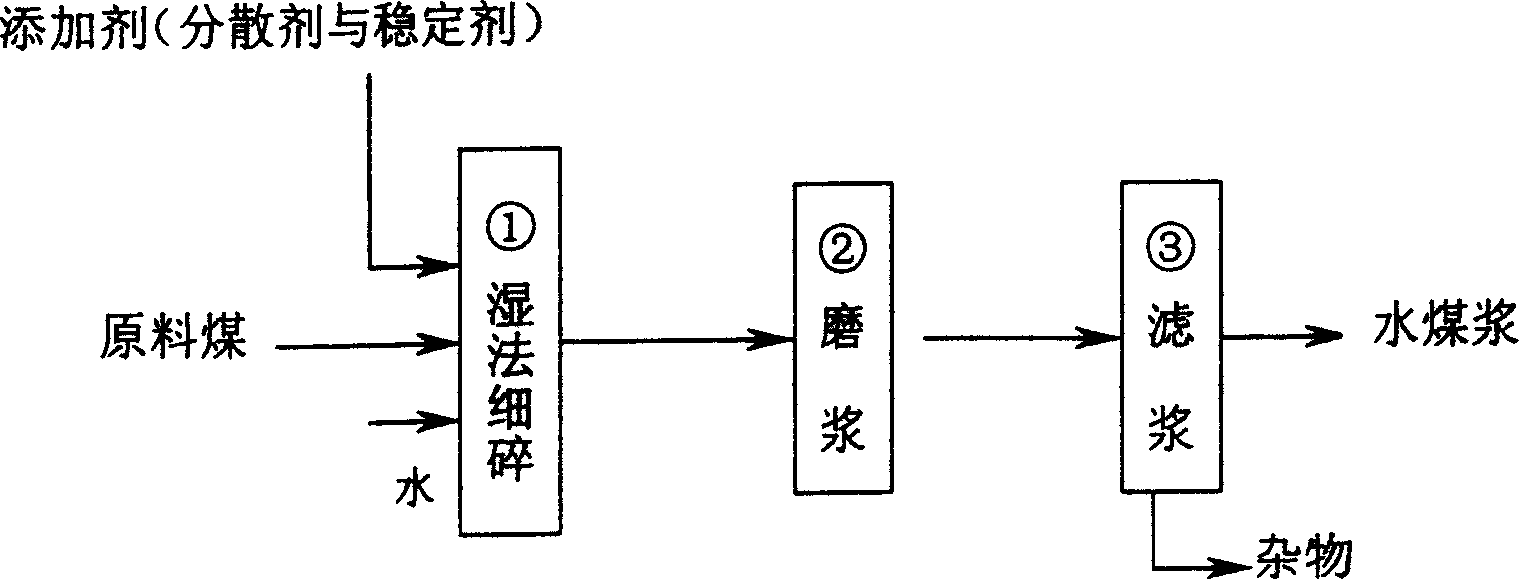

[0026] The pulping system with the φ2.4×8.0m wet ball mill designed by the inventor as the core used in the method of the present invention is taken as an example for illustration. according to figure 2 Shown, the technological process of coal-water slurry preparation method of the present invention is:

[0027] 1. fine crushing: the raw coal with a particle size of ≤100mm and a weight of 100t (being 7% in moisture) is weighed by a coal belt scale, and then sent into a vertical shaft type linear acceleration crusher (this crusher is owned by the applicant with a patent No. : ZL02232954.4 patented product) finely crushed to a particle size ≤ 2mm, sent to the belt conveyor.

[0028] 2. Premixing: the above-mentioned belt conveyor sends the finely crushed raw coal and the 0.93t coal-water slurry additive (this additive is a mixture of a dispersant and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com