Alumina having bimodal pore structure, its preparing method and catalysts made therefrom

A technology of alumina and catalyst, applied in the field of alumina, can solve the problem that alumina carrier does not have chemical and physical stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Alumina preparation method

[0024] The alumina of the present invention is prepared by a two-step precipitation process. Seeds are formed under tightly defined conditions of temperature, pH and flow rate. The temperature of the seed slurry is then raised to a higher level. Precipitation is restarted at this higher temperature under strictly defined conditions of temperature, pH and flow rate. The low temperature seeding step ensures a narrow defined pore size distribution, while the high temperature precipitation step produces high pore volume and controls the diameter of the main peak.

[0025] In a first step, alumina seeds are produced by precipitation from an aqueous solution of the reagent at a temperature between about 25°C and 60°C, preferably between about 35°C and 50°C. Although a combination of aluminum sulfate and sodium aluminate reagents is preferred, any combination of reagents that results in the formation of an alumina hydrogel or precipitation of al...

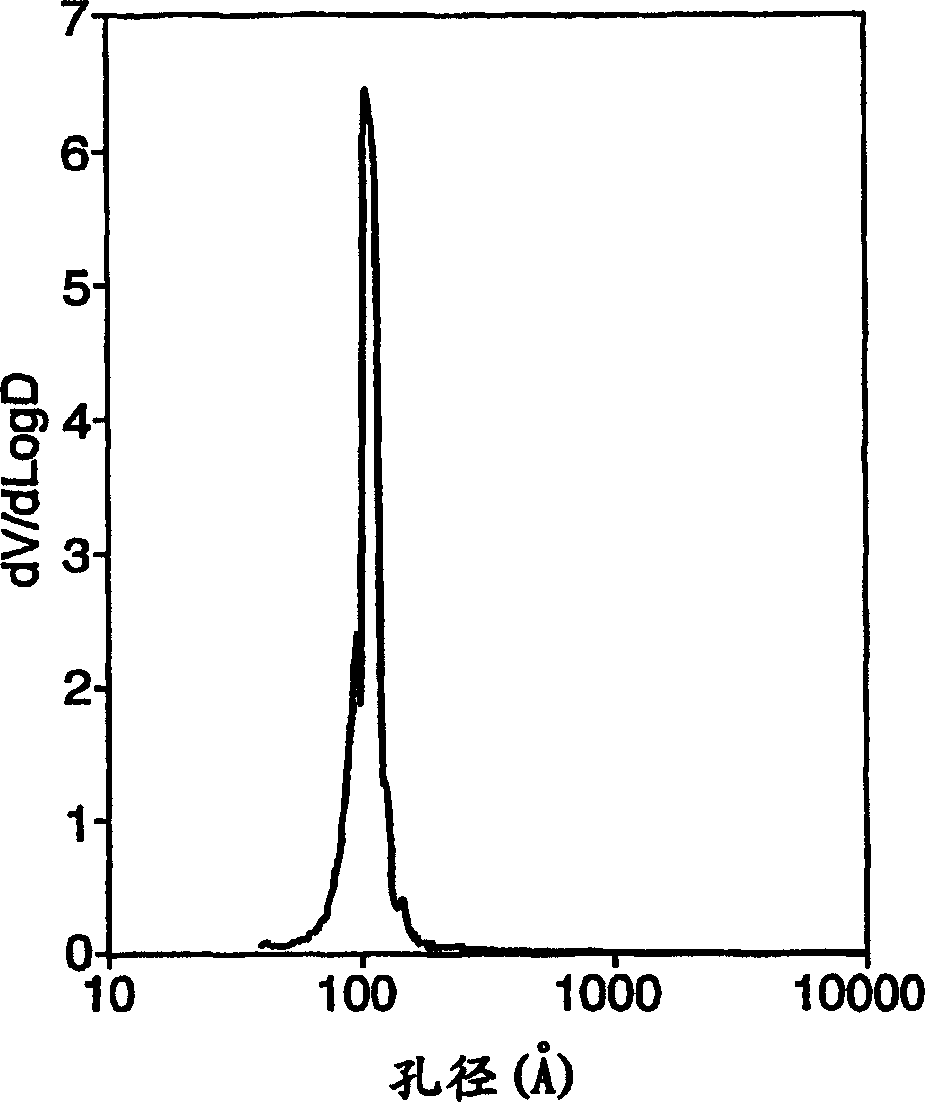

Embodiment 1

[0064] This example describes the preparation of the inventive alumina to produce a hydroprocessing catalyst with improved initial activity and stability for use in the treatment of tar sands derived gas oils.

[0065] 200kg water and 5kg aluminum sulfate aqueous solution (Al 2 o 3 Content is 8%) add in the stirred tank. The temperature was brought to 41°C. Then add the same aluminum sulfate solution continuously at a rate of 1.4kg / min for 8min, while adding sodium aluminate aqueous solution (Al 2 o 3 content of 23.5%) to make the pH value reach 8.5 and keep it in the range of 8.3-9.0, while cooling water is circulated through the jacket of the kettle to keep the solution temperature at 41°C. The temperature of the resulting slurry was then raised to 60°C with stirring but without addition of reagents. Reagent addition was restarted for about 50 min while cooling water was circulated through the jacket of the kettle to maintain the temperature at 60°C and the pH in the ra...

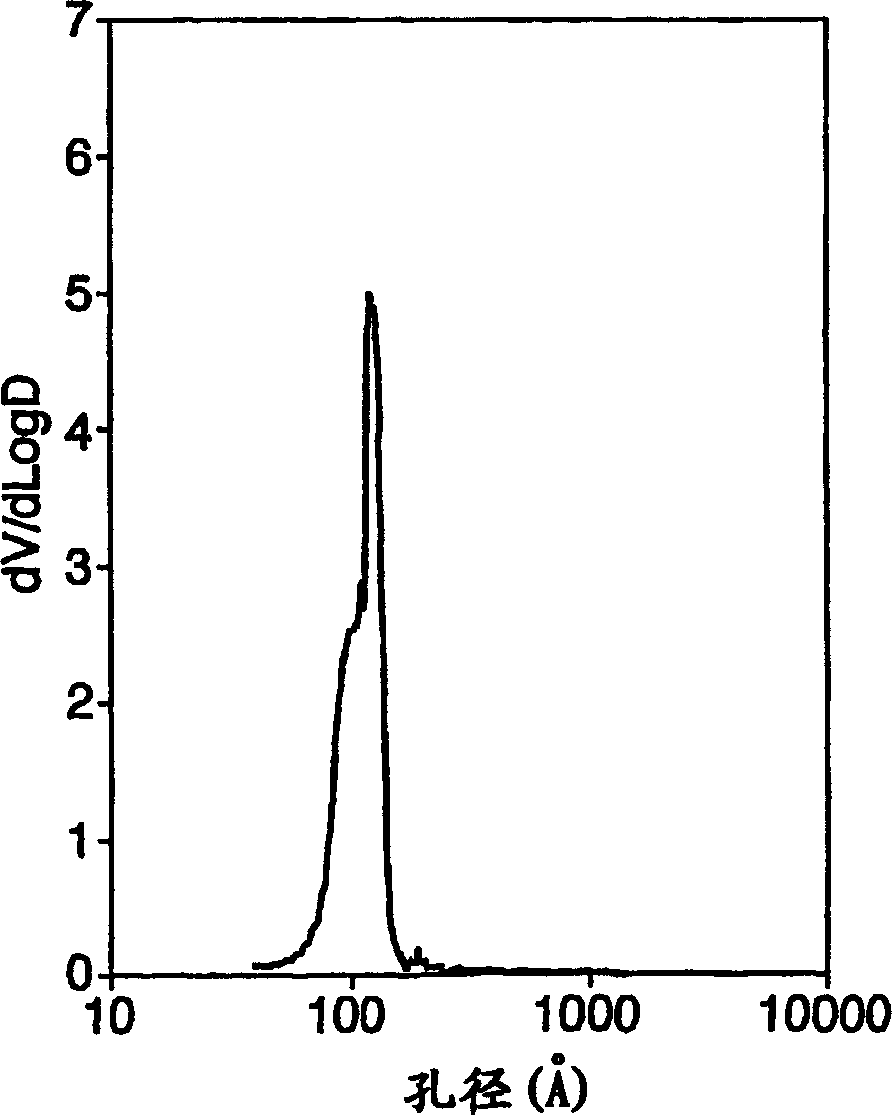

Embodiment 2

[0067] This example describes the preparation of aluminas of the present invention wherein high impact temperatures are used to produce extruded supports with high pore peaks that are particularly useful in the production of hydrodemetallization catalysts.

[0068] 200kg of water and 5kg of aluminum sulfate aqueous solution (Al 2 O 3 content of 8%) was added to the stirred tank. Bring the temperature to 33°C. Then the same aluminum sulfate solution was added continuously for 20 min at a rate of 1.4 kg / min, while adding sodium aluminate aqueous solution (Al 2 O 3 content of 23.5%) to make the pH value reach 8.5 and keep it in the range of 8.3-8.6, while cooling water is circulated through the jacket of the kettle to keep the solution temperature at 33°C. The temperature of the resulting slurry was then brought to 81°C with stirring but no reagent addition. Reagent addition was resumed for about 40 min while cooling water was circulated through the jacket of the kettle to k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com