Linear motor

A technology of linear motor and reciprocating linear motion, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of curved surface deformation, increased eddy current loss, difficulty in reducing cogging stress arc shape, etc., to prevent Effects of deformation, reduction of eddy current loss, reduction of mass deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

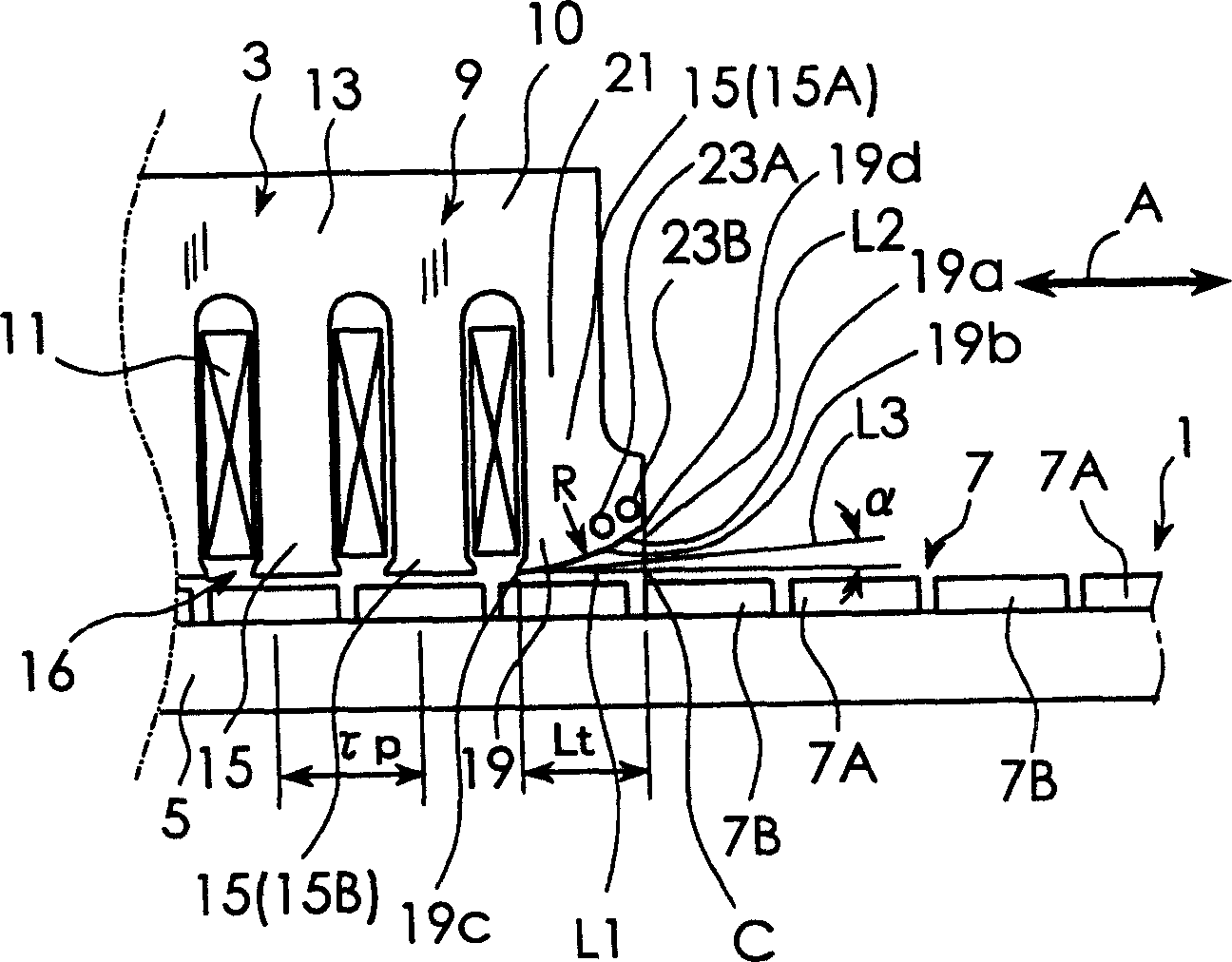

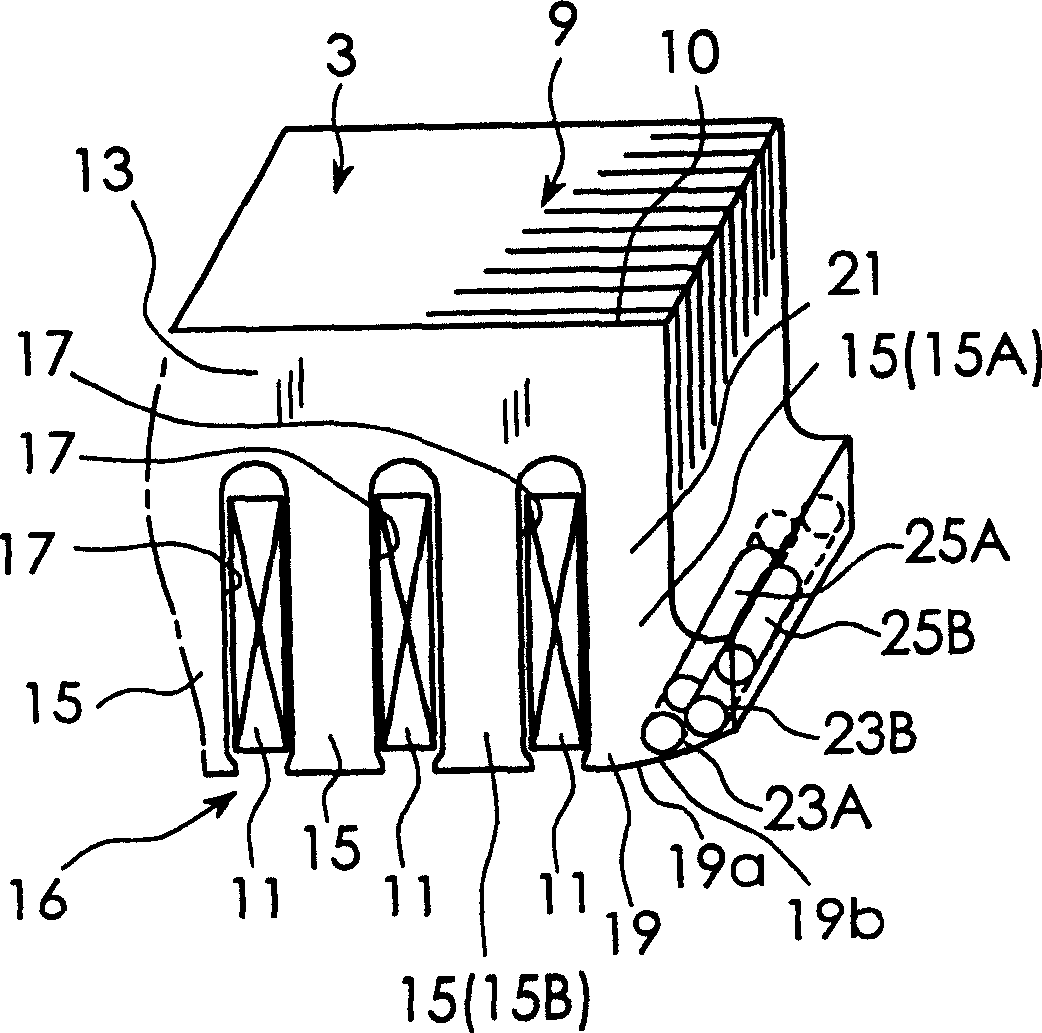

[0022] Hereinafter, preferred embodiments for carrying out the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram for explaining the structure of the linear motor which implements one Example of this invention. figure 1 A part of the stator 1 and a part of the mover 3 are represented in . Such as figure 1 As shown, the linear motor of this embodiment has a stator 1 and a mover 3 . The stator 1 has a structure in which a magnetic pole row 7 is provided on a base plate 5 . The magnetic pole row 7 is formed by alternately arranging a plurality of N-pole permanent magnets 7A and a plurality of S-pole permanent magnets 7B.

[0023] The mover 3 is movably supported on the stator 1 by a support mechanism not shown. Such as figure 2 As shown in the perspective view of , the mover 3 includes an armature composed of a magnetic core 9 and multi-phase field coils 11 . . . The magnetic core 9 is formed by laminating a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com