Back-to-light module

A backlight module and light source technology, which is applied in optics, optical filters, nonlinear optics, etc., can solve the problems of difficult lamp manufacturing process and inability to completely filter ultraviolet rays, and achieve convenient and simple procedures, save manufacturing costs, and facilitate heavy industry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

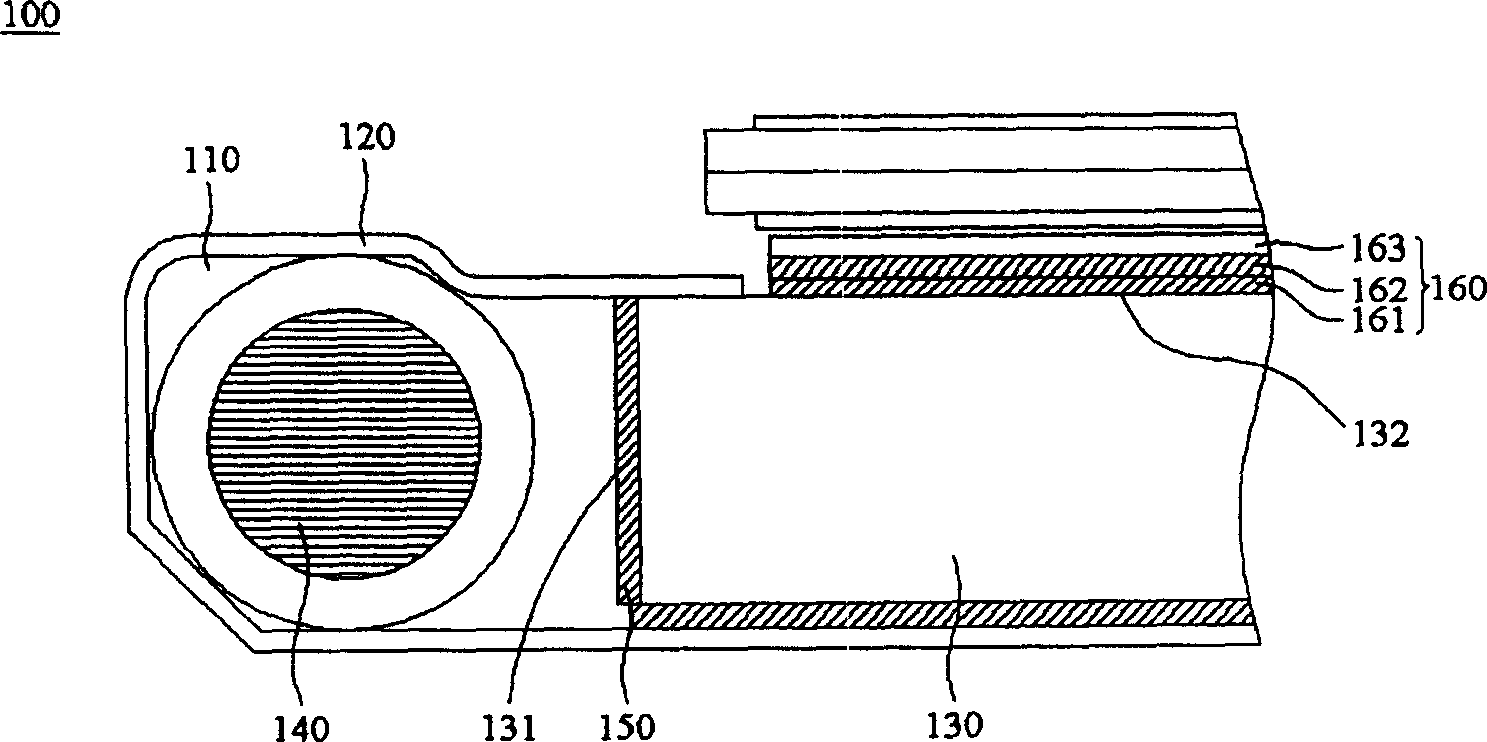

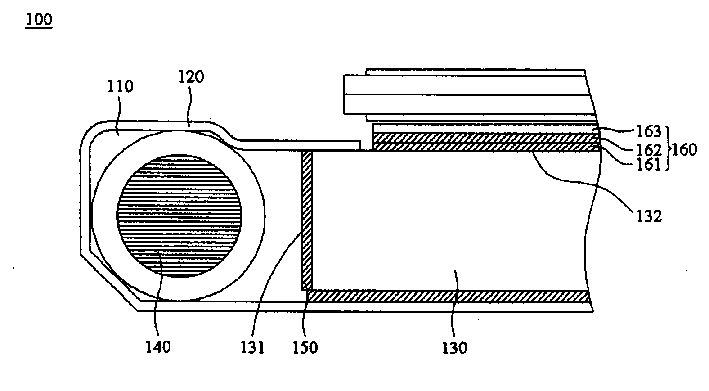

[0008] figure 1 It is the first embodiment of the backlight module of the present invention. The backlight module 100 has a cavity 110 formed by a first plate and a second plate. In this embodiment, the first plate is a reflective plate 120, the second plate is a light guide plate 130, and the light guide plate 130 has a light incident surface 131 and a light-emitting surface 132 ; the lamp tube 140 as a light source is disposed in the cavity 110 , the light emitted by the lamp tube 140 enters the light guide plate 130 through the light-incoming surface 131 , and then leaves the light-guiding plate 130 through the light-emitting surface 132 .

[0009] In order to filter the ultraviolet rays in the light emitted by the lamp tube 140, a filter device is provided on the light incident surface 131 of the light guide plate 130. In this embodiment, the filter device can be a filter film 150, which is directly attached to the light incident surface 131. On the surface 131 , or use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com