Well drilling pump piston

A technology for drilling pumps and pistons, which is applied in the field of pistons used in single-acting mud pumps. It can solve the problems that air cannot be completely prevented from entering the cylinder liner, water hammer cannot be effectively solved, and water hammer cannot be completely eliminated. Shock phenomenon, reduce maintenance time, facilitate the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

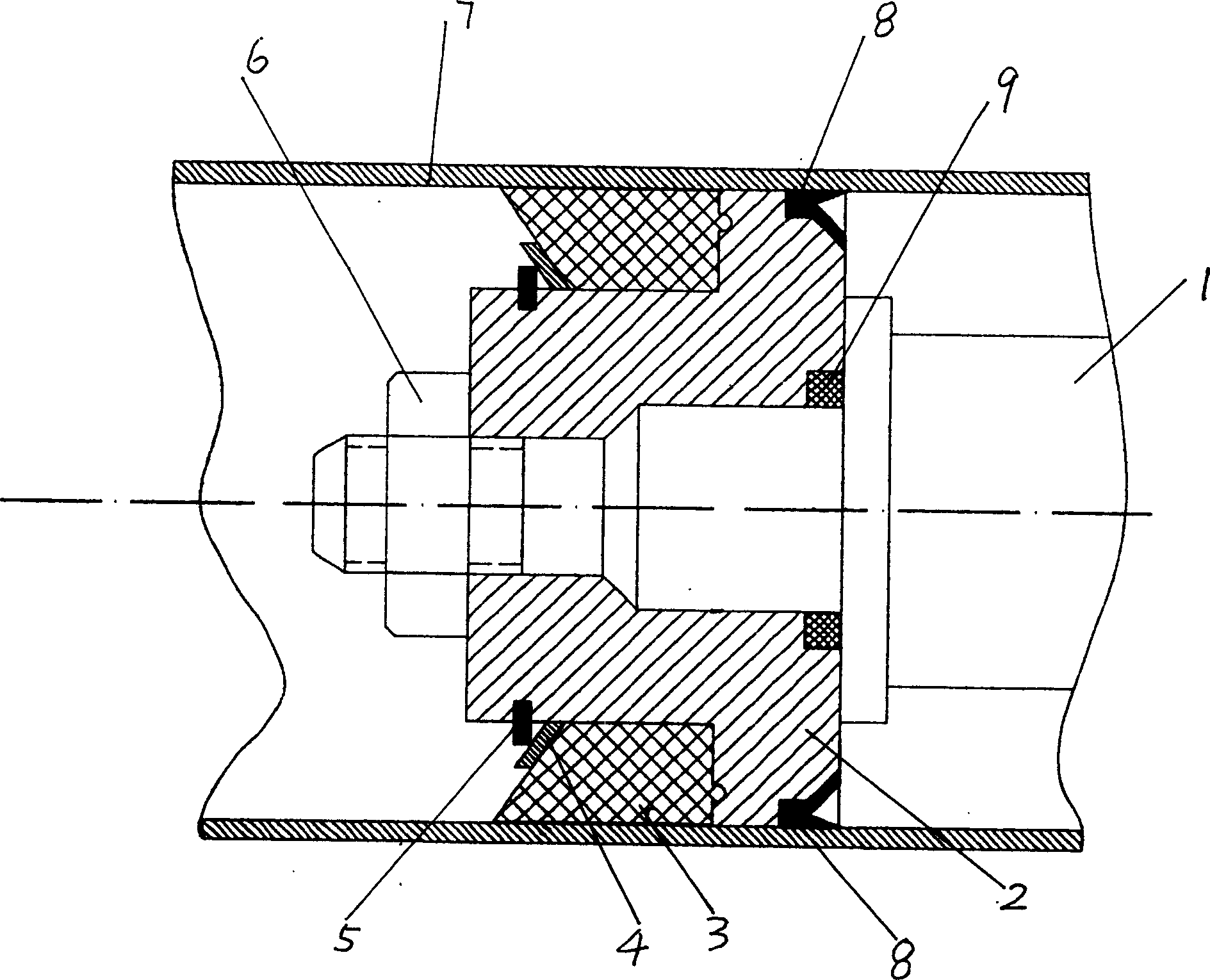

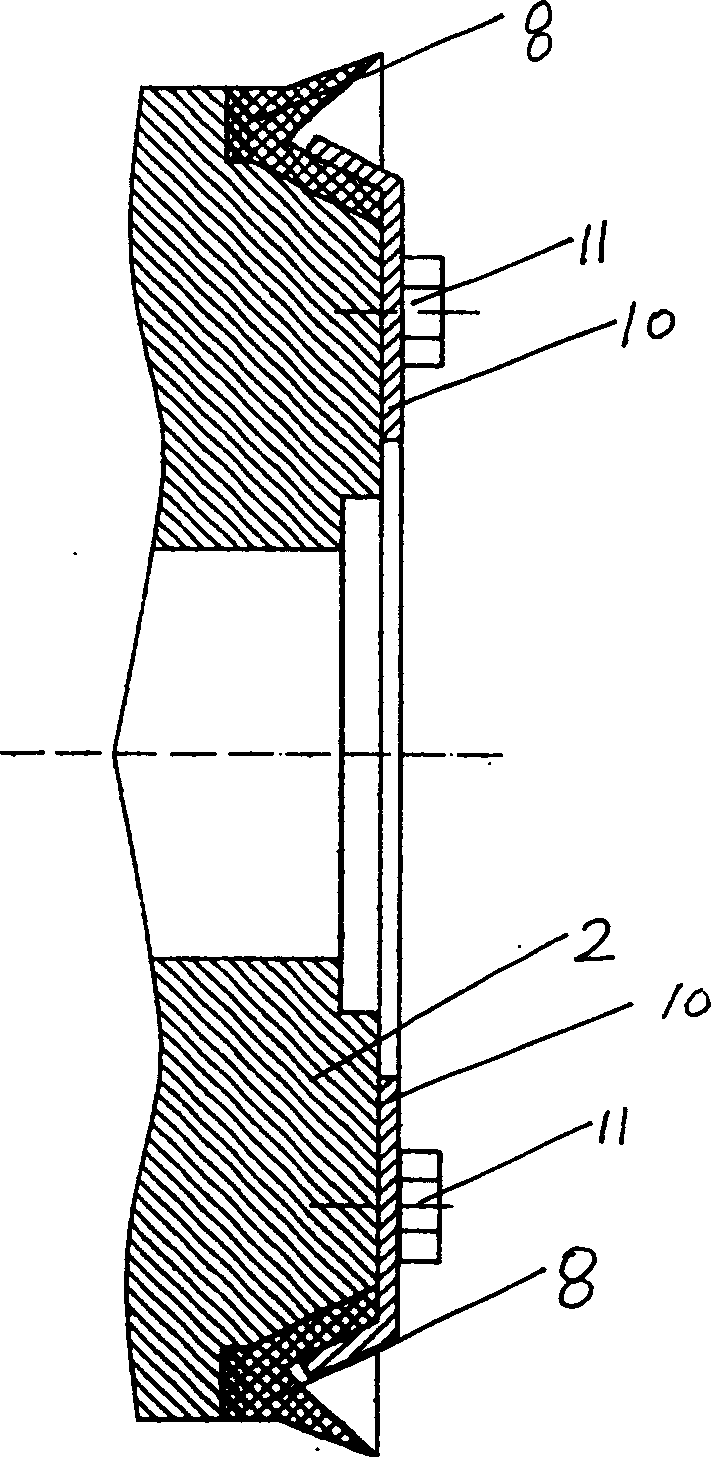

[0018] A specific structure of the novel drilling pump piston of the present invention is as follows: figure 1 As shown, it includes piston body 2, piston rod 1, rubber sealing ring 3, rubber sealing ring 9 and air sealing ring 8; the combined section of piston rod and piston body is processed with threads, and the piston body 2 and piston rod 1 pass through the nut 6 Realize threaded connection and combine into one; rubber sealing ring 3 is installed on the front section of the piston body, fixed with baffle plate 4 and circlip 5; rubber sealing ring 9 is installed on the contact surface between the piston body and the piston rod; air seal Ring 8 is a "V"-shaped rubber ring, which is fixedly connected to the rear end of the piston body with its opening facing away from the piston body. The fixed connection method is as follows: figure 2 As shown, the pressure plate 10 and the screw 11 are closely combined with the piston body.

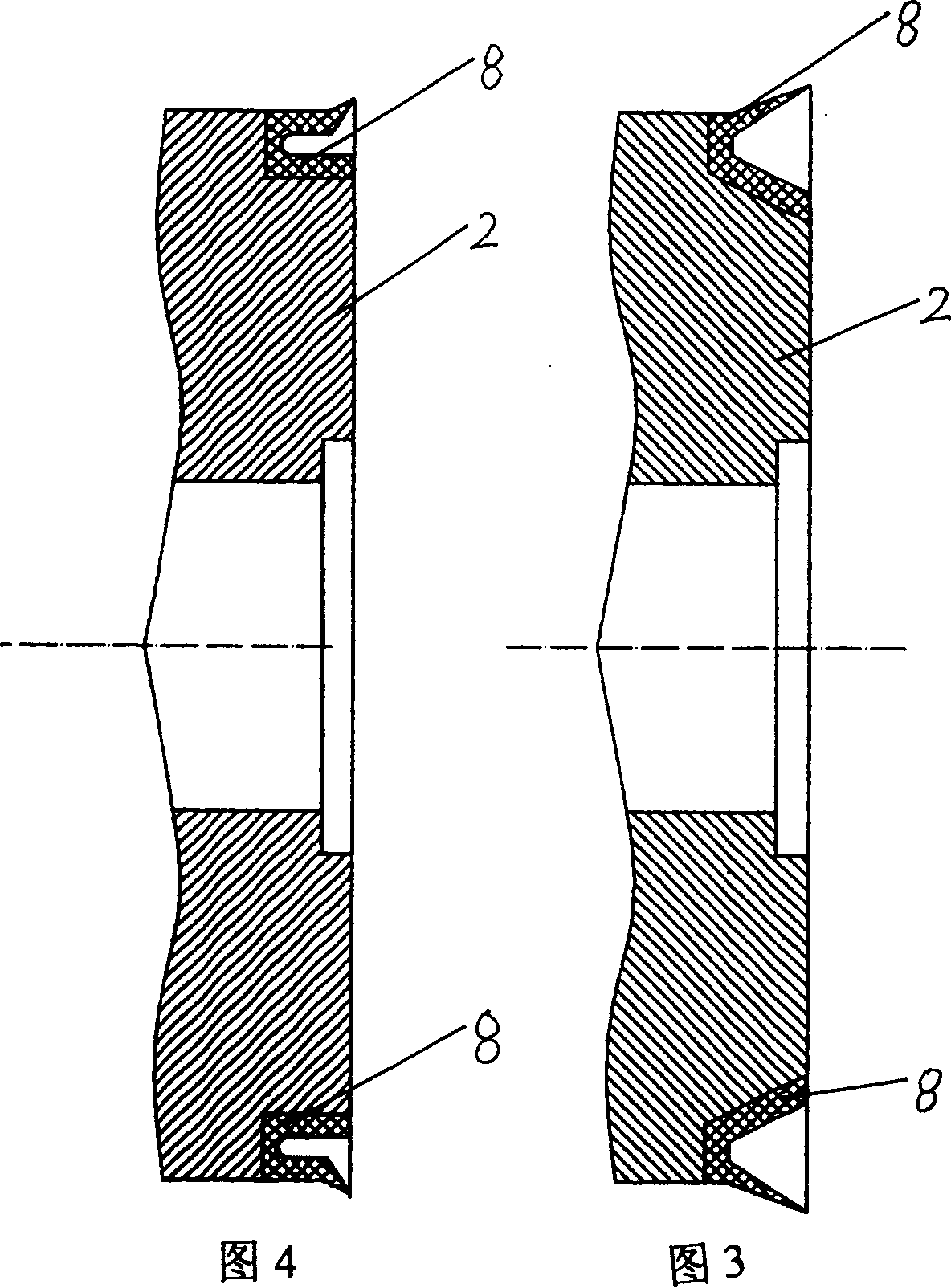

[0019] The air blocking ring 8 can also be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com