Iron with foam moistening means

A technology of heating device and foaming device, which can be applied to hand irons, washing devices, household appliances, etc., and can solve the problem of unsatisfactory moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

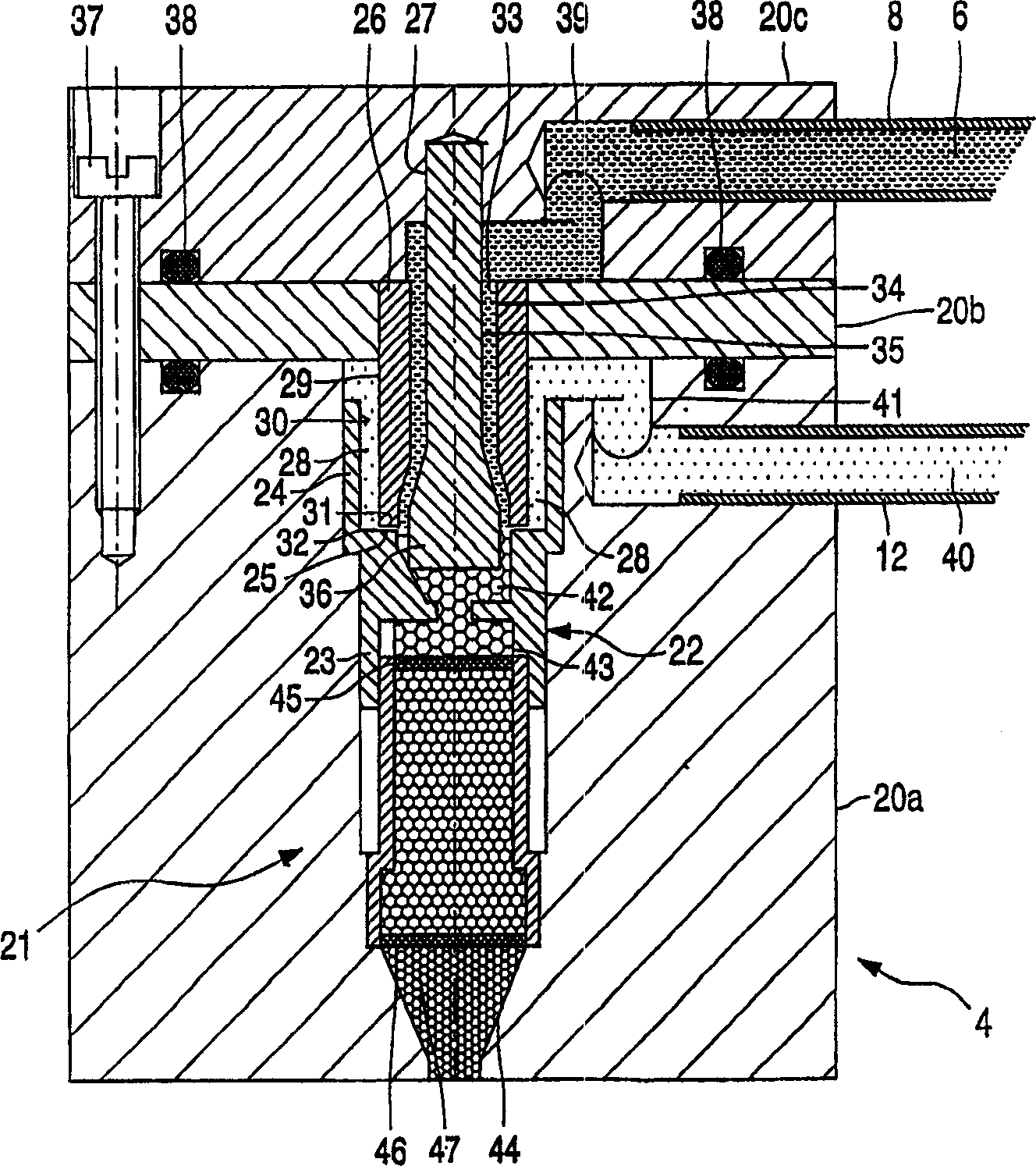

[0023] exist figure 1 In the first embodiment shown, the iron comprises a housing 1 with a soleplate 2 heated by means of an electric heating element 3 . The foam is generated by the nozzle unit 4, the work of which will be referred to below figure 2 illustrate. The iron comprises a reservoir 5 containing a foaming liquid 6 under pressure. The storage tank 5 may be, for example, a detachable cassette. Foaming liquids contain a small amount of surfactant in order to lower surface tension. The concentration of surfactant must be only above the critical micelle concentration (CMC) in order to generate foam. In practice, this means a concentration of about 0.2-0.5 weight percent. The reservoir 5 has an outlet 7 connected by a conduit 9 to a first inlet 8 of the nozzle unit 4 . The flow rate of the foaming liquid from the reservoir to the nozzle unit can be adjusted if desired. The iron also comprises an electric air pump 10 , the outlet 11 of which is connected to a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com