Selective iron weighing block

A counterweight and shell technology, which is applied to heavy objects, dumbbells, etc., can solve the problems of short service life, loud motion noise, and labor-intensive work, and achieve the effects of low cost, low motion noise, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

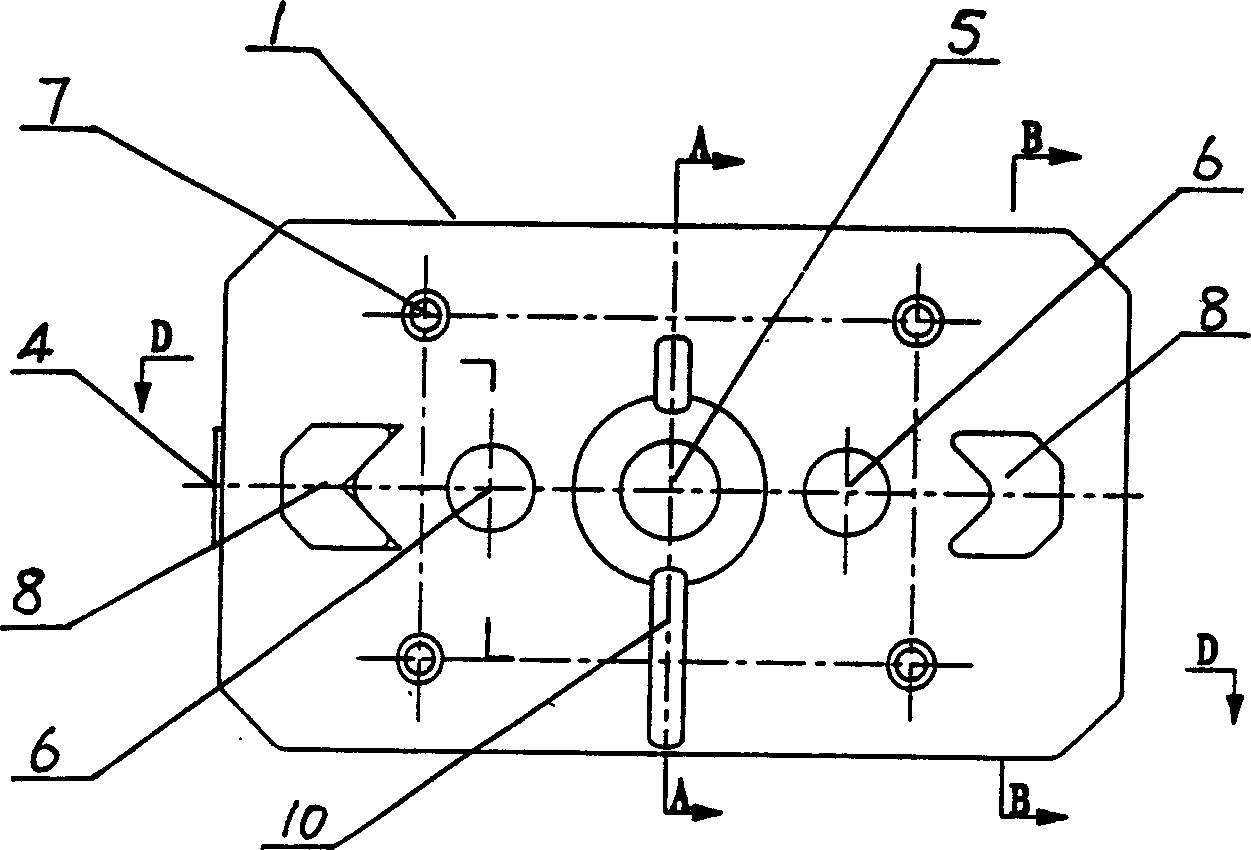

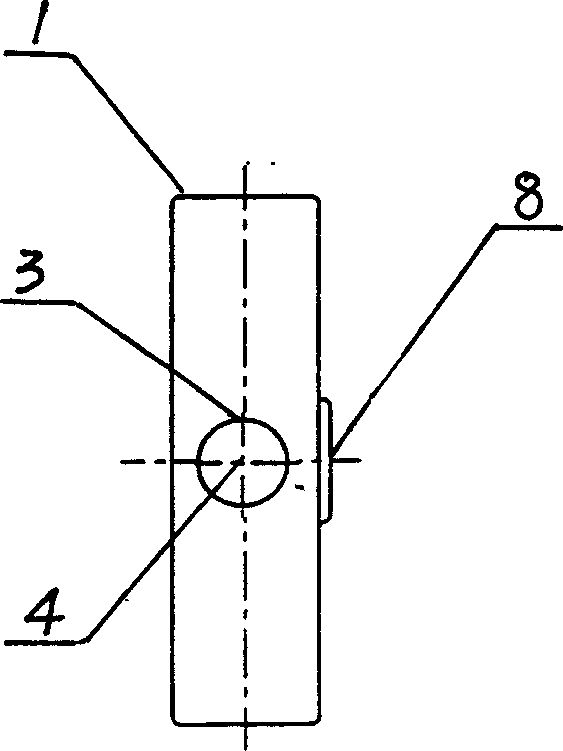

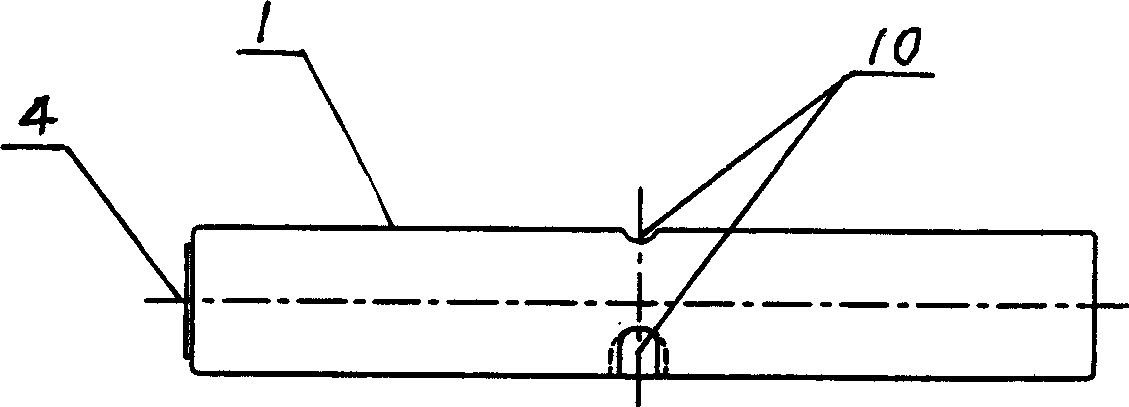

[0020] Below in conjunction with accompanying drawing, embodiment of the present invention is described in detail:

[0021] Reference attached Figure 1-7 , In the embodiment of the present invention, it includes a shell 1 and a filler 2; the shell 1 is set as an octagonal box containing a cavity, and the outer surface of the box is provided with a filling hole 3 and a closing plug 4 , the filler 2 is injected and solidified in the cavity of the shell 1 through the filling hole 3, and the closing plug 4 closes the filling hole 3; the end surface of the box is provided with a mounting hole 5, a positioning hole 6, a reinforcing rib 7, and a positioning bump 8 , positioning groove 9, latch groove 10; mounting hole 5 and positioning hole 6 are sliding through holes, and four reinforcing ribs 7 are inserted into the cavity of shell 1 to support the end face of the connecting box; one port of mounting hole 5 is set as a horn Two positioning protrusions 8 are symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com