Vehicle body assembling method

An assembly method and vehicle body technology, applied to motor vehicles, auxiliary devices, vehicle parts, etc., can solve problems such as spending a lot of time and effort, and reducing positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, a preferred embodiment is specifically cited below, together with the accompanying drawings, and is described in detail as follows:

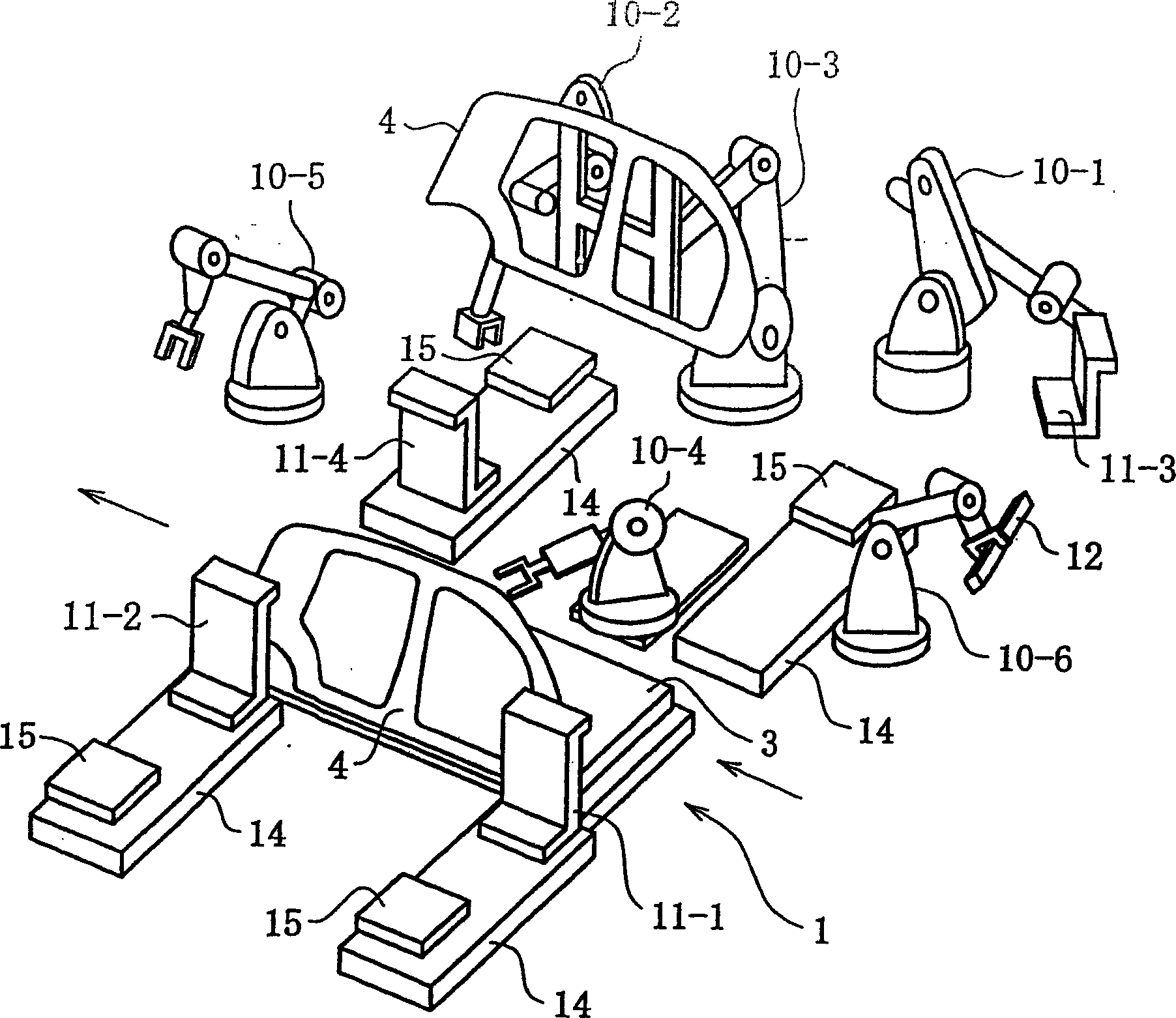

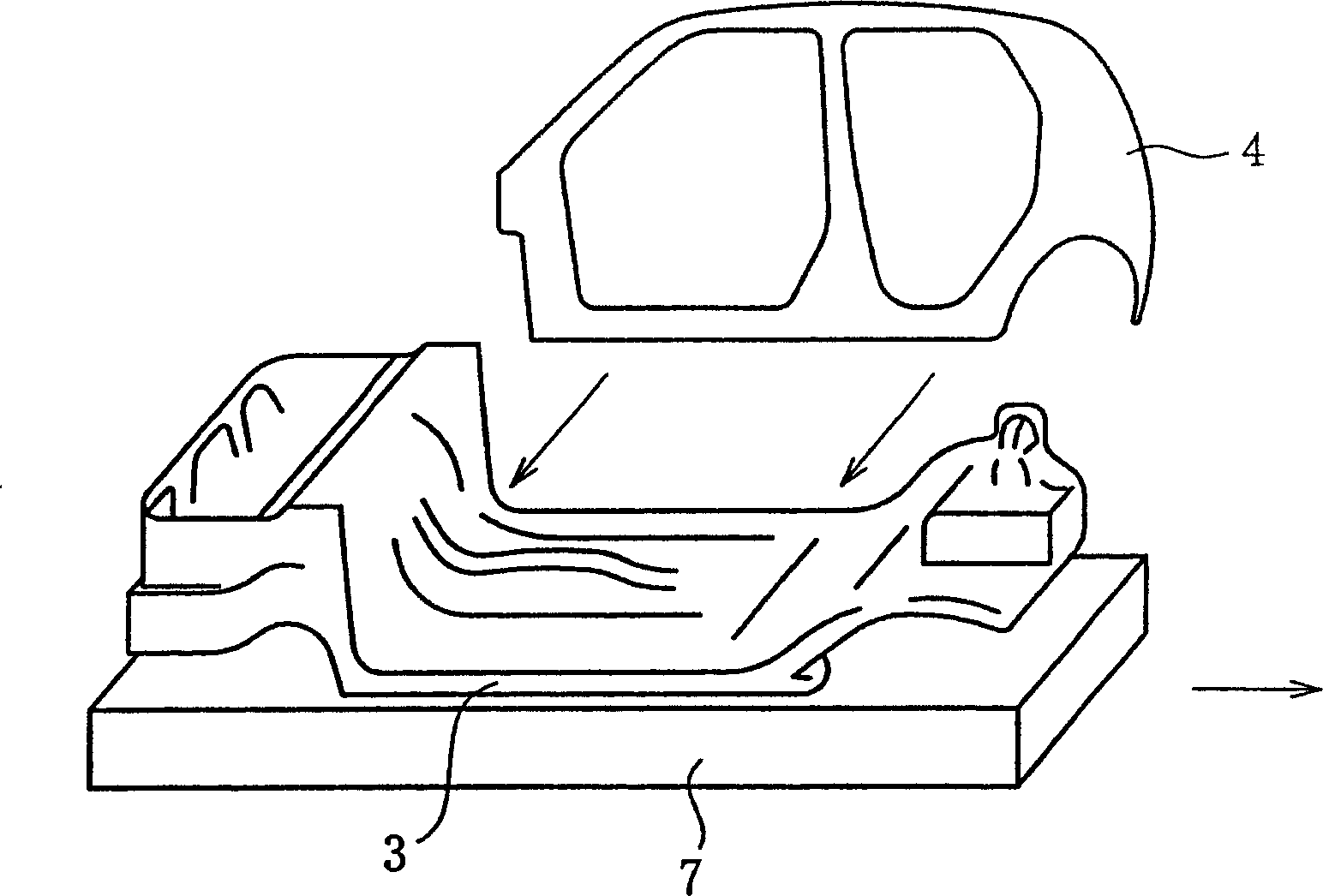

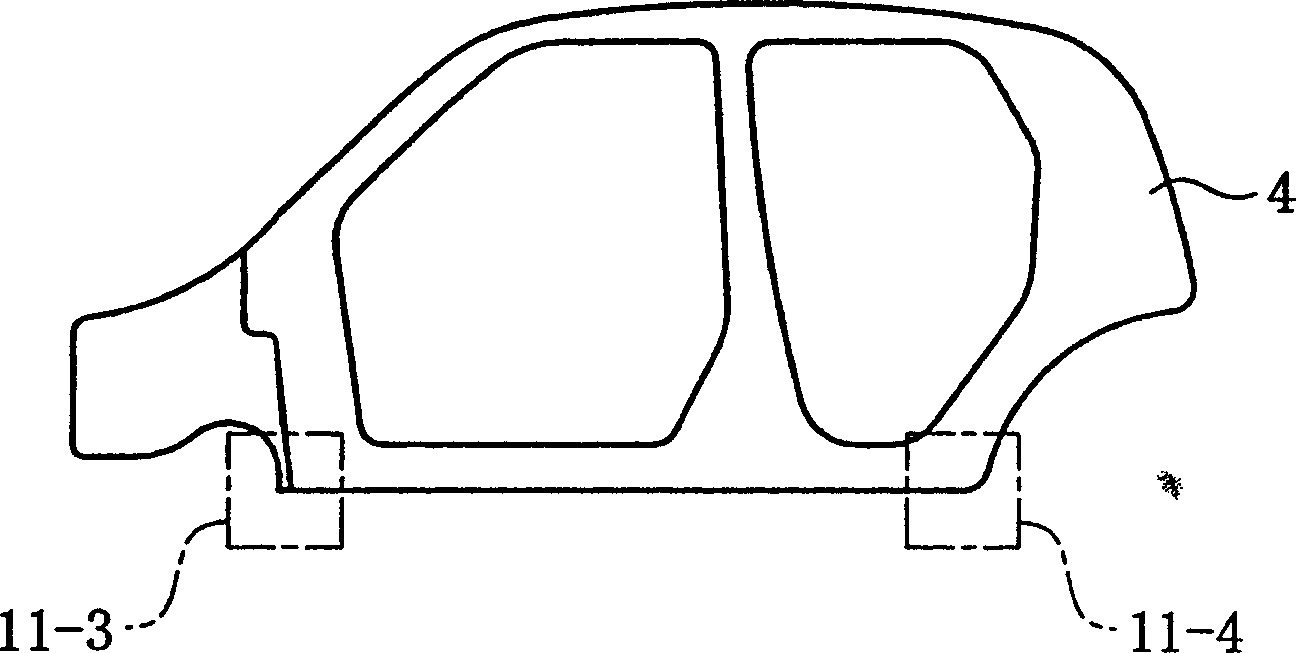

[0066]FIG. 1 is a simplified diagram of a side member assembly station implementing the present invention. As shown in FIG. 5 , the side member assembly station 1 is arranged at a designated position of the vehicle body production line. The side piece assembly station 1 is located upstream of the car body production line 2, that is, the bottom shell 3 production line shown in FIG. 2 . The rear end of the bodywork faces forward and is transferred to the side piece assembly station. In the sequence of the production line shown in Figure 5, downstream of the side member assembly station 1 is a rough roof placement station (roof coarse placement station) 5 and a roof assembly station 6 for completing the final welding edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com