Advanced supporting and protecting technology for cracked top plate of digging operation face

A technology for excavating working faces and crushing roofs, which is applied to supporting the roof beams of mine roofs, mining equipment, earthwork drilling and mining, etc., can solve the problems of poor stability and low support strength, and achieve improved safety, convenient materials, and effective obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

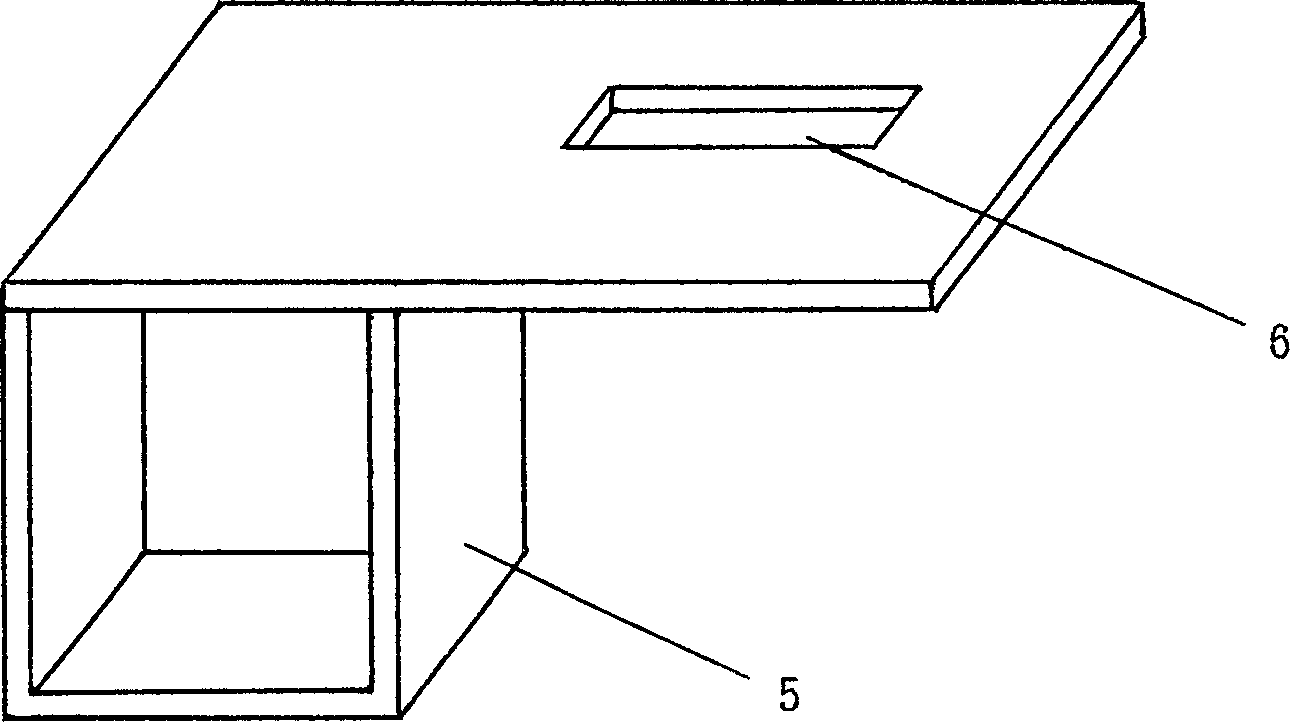

[0034] figure 1 Show the present invention's head-on broken roof advance roof protection technology, its operation method is as follows:

[0035] ① First, on the roadway contour line, determine the position of the front probe beam (1), that is, the drilled hole. When pointing the eyes, make the roadway top supporting anchor rod (4) in a straight line, and the borehole that is done for the front probe beam (1) is next to it. The spacing of boreholes, that is, the number of front probe beams (1) depends on the size of the roadway section. Generally, when the width of the roadway is below 3m, two groups are used; when it is more than 3m, three groups are used.

[0036] ②Use a large-diameter cone drill to drill holes, and the drilling direction should form an upward angle of 2-3° with the roof line, so that when the front probe beam is inserted into the roof, it will be in an upward state to enhance the support strength for the roof. Drilling depth is 200±100mm higher than the c...

Embodiment 2

[0047] Figure 4 , 5 Show the advance support technology of the broken roof of the coal mining face of the present invention, and its operation method is as follows:

[0048] ①In the gap of the regular pillar (15) on the coal mining face, first select the drilling position, that is, the position of the front beam (1): stick to the top of the working face; the distance between the drill holes, that is, the frame spacing of the front beam (1) (L), depending on the brokenness of the roof; when the roof falls seriously, it is controlled at about 1m, and when the roof is slightly better, it can be slightly larger.

[0049] ②According to the elevation angle direction of α=2~3° with the top plate, use a large-diameter cone drill to drill holes. The hole depth (h) should be about 200mm longer than the cycle footage. The diameter of the large-diameter cone drill bit is 130±3mm. The hexagonal hollow steel drill pipe and water-type shank are used for ore blending. It is driven by a coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com