Lift support mechanism of plastering device for plastering machine

A technology of a support mechanism and a plastering machine, which is applied in the direction of building structure and construction, can solve the problems of high manufacturing precision, difficult assembly, and difficult adjustment, and achieves the effect of smooth work, not easy to get stuck, and easy to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

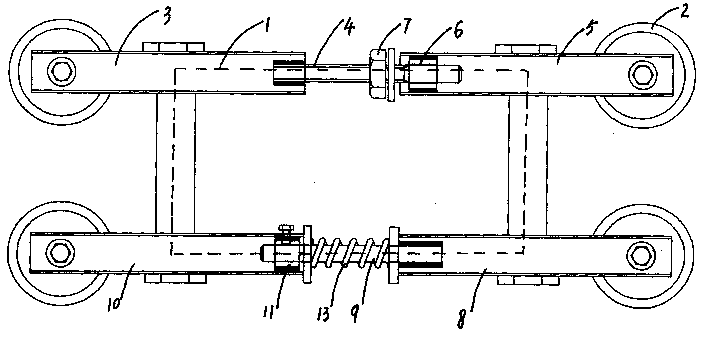

[0010] Such as figure 1 As shown, the lifting support mechanism of the plastering device of the plastering machine is composed of a square frame body 1 and four roller devices installed on the four corners of the square frame body 1, and the rollers 2 of the four roller devices are in the same plane parallel to the square frame body 1 Inside, each side of the quadrilateral formed by the central points of each roller 2 is correspondingly parallel to the four sides of the square frame body 1, and the roller 2 is a pulley with grooves on the wheel surface. The upper and lower horizontal main rods of the square frame body 1 are formed by inserting and fixing the left and right two sub-rods respectively. One section of the sub-rod 3 of one main rod is fixed with a section of screw 4, and the other section is divided into two sections. The connecting end of the rod 5 is fixed with a sleeve 6, the insertion end of the screw 4 is inserted into the sleeve 6, and a compression nut 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com