Thermocouple temperature monitoring method and system for air preheater

An air preheater and thermocouple technology, which is applied in the direction of thermometers, thermometers, and combustion methods that use electrical/magnetic components directly sensitive to heat, can solve problems such as false alarms, heating components catching fire, and fire formation. , to achieve the effect of improving reliability, increasing reliability and service life, and reducing judgment interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and embodiment, take the air preheater of 300MW boiler as an example.

[0034] The devices required for the present invention include:

[0035] (1) 30 dedicated thermocouple probes;

[0036] (2) Special thermocouple probe installation tube;

[0037] (3) Control cabinet

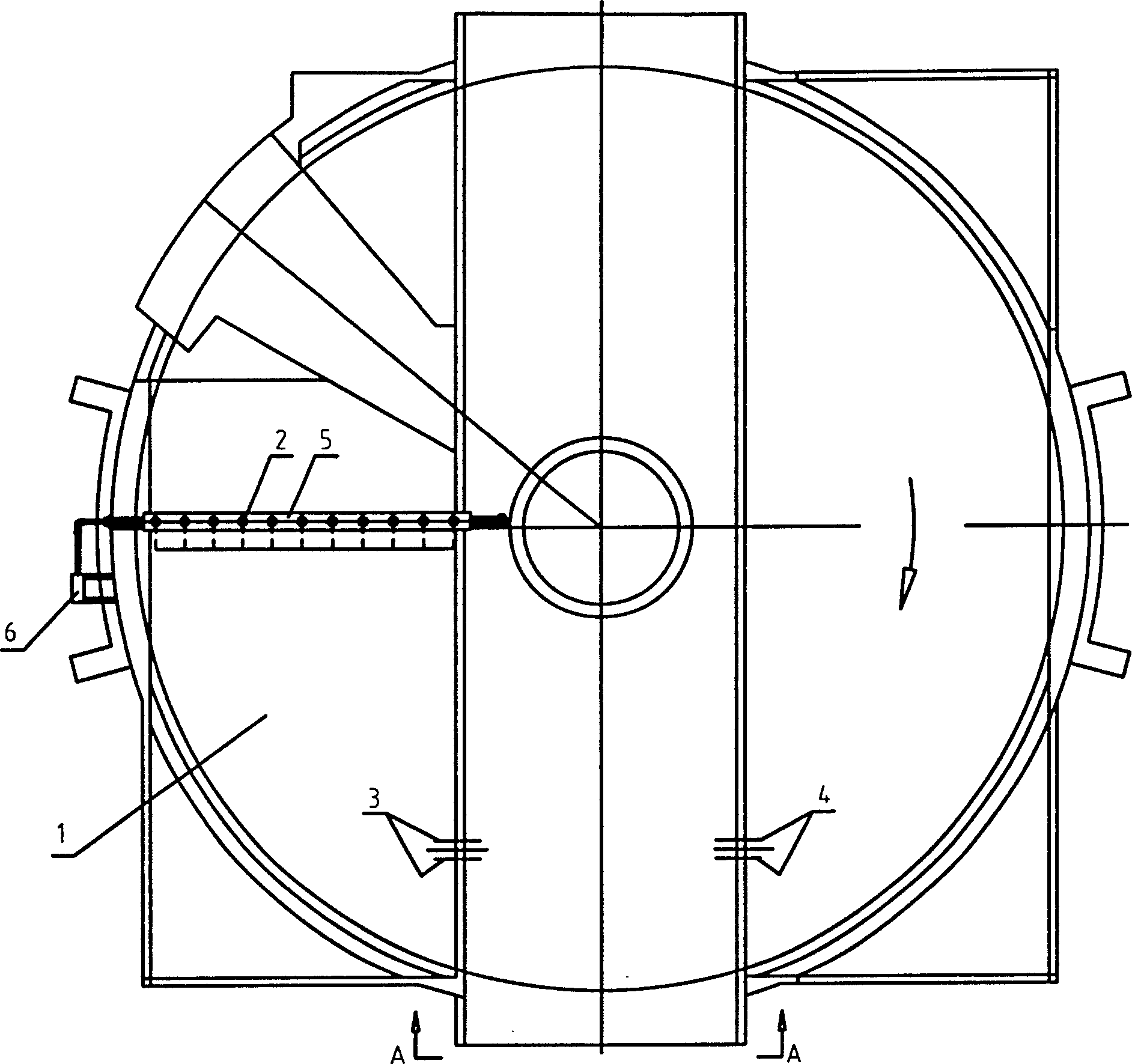

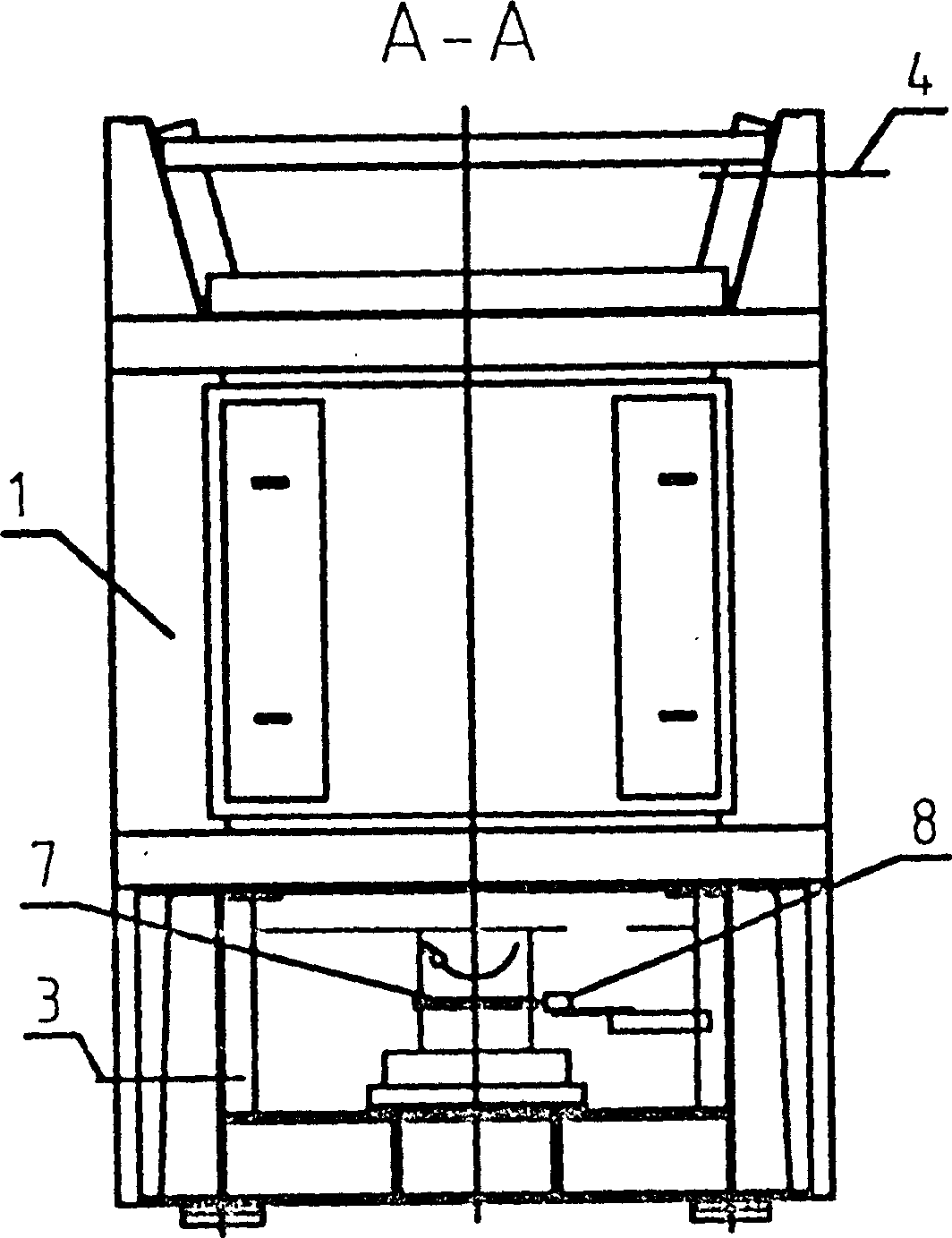

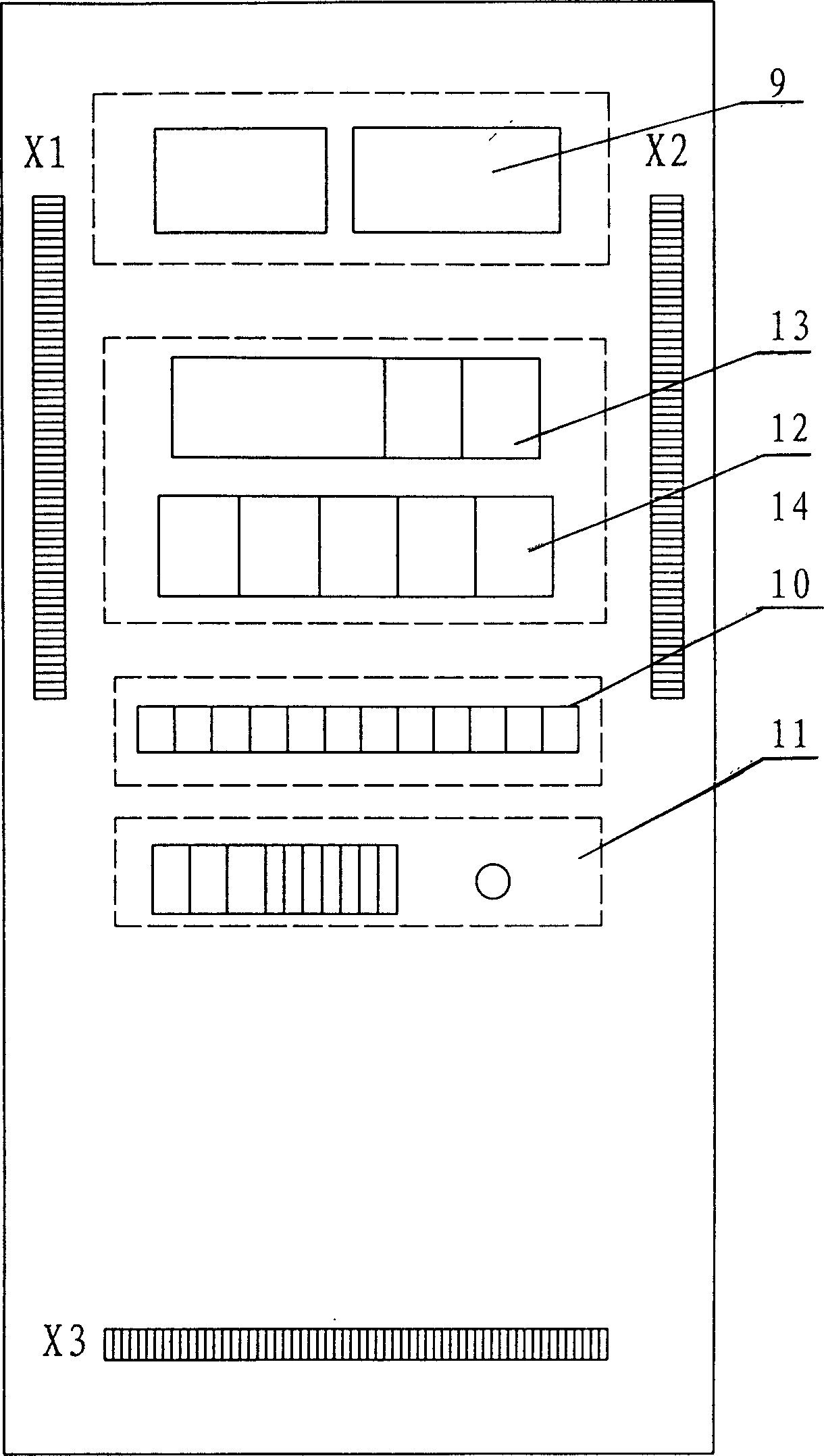

[0038] Such as figure 1 , 2 As shown, it is the layout diagram of the thermocouple probes of the air preheater, which consists of air preheater 1, 11 special thermocouple probes at the two groups of air outlets 2, and 2 special thermocouple probes at the two groups of air inlets 3 , Two sets of flue gas inlets are composed of 2 dedicated thermocouple probes 4, thermocouple group installation tube 5, local junction box 6, stop alarm sensor hoop 7, and proximity switch 8.

[0039] Install 11 special thermocouple probe sets 2 along the radial direction at the air outlets of the A and B sides of the air prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com