Quality detecting device and method applicable to air reactor

A technology for air-core reactors and detection devices, which is applied in the direction of measuring devices, measuring electrical variables, single semiconductor device testing, etc., and can solve the problems of low detection accuracy by voltage method, difficulty in circuit safety, and burnt cores of air-core reactors. , to achieve the effect of reducing judgment interference, ensuring quality reliability, and ensuring consistent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

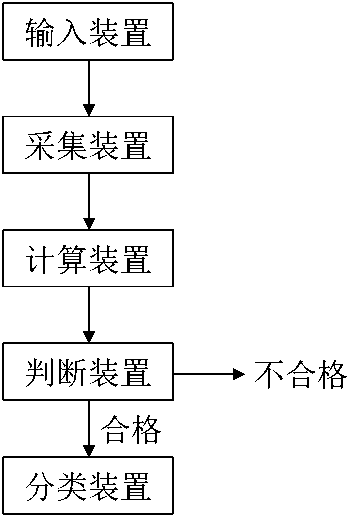

[0038] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0039] Such as figure 1 As shown, a quality detection device suitable for an air-core reactor, the quality detection device includes an input device, an acquisition device, a calculation device, a judgment device, and a classification device connected in sequence; wherein,

[0040] The input device is connected with the high-frequency current generator for inputting a high-frequency current with a preset frequency into the air-core reactor to measure the target information of the air-core reactor after passing the high-frequency current;

[0041] The collection device is used to collect target information of the air-core reactor within a preset period;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com