Mini DC motor

A DC motor and motor technology, applied in the shape/style/structure of winding insulation, can solve the problems of high production cost and defective rate, and achieve the effect of improving production efficiency, improving insulation effect and increasing winding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

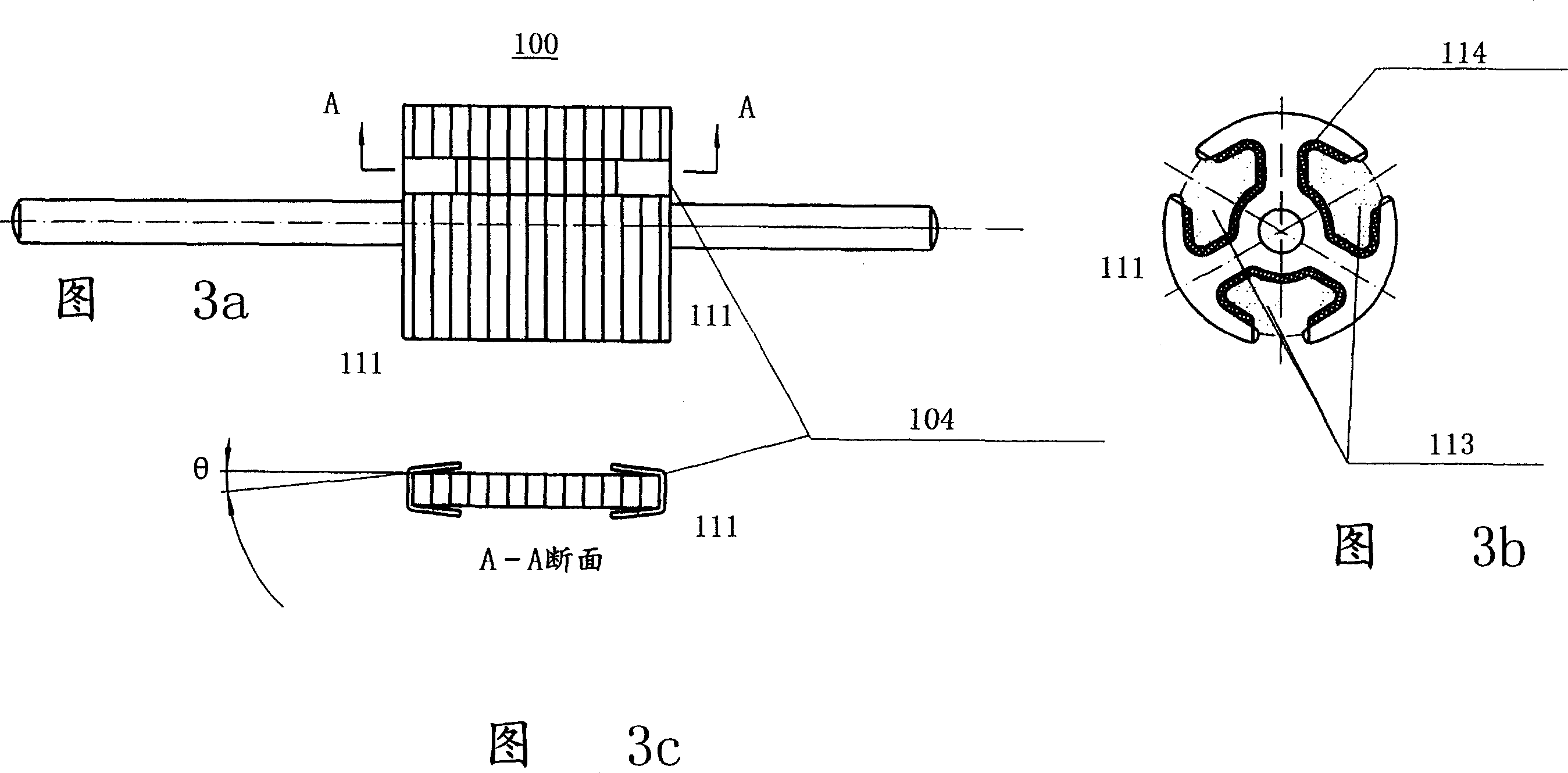

[0025] see below Figures 5a-5b and 6a-6b, describe preferred embodiments of the invention. In Figures 5 and 6, with figure 1 The corresponding parts in -4 adopt the same reference numerals.

[0026] Figures 5a-5b shows the state in which the rotor of the present invention is stretched when the insulating sheet is installed. Such as Figures 5a-5b As shown in , it is assumed that the gap between the edge of the insulating sheet 111 bent at right angles and the iron core is T1, the thickness of the edge of the insulating sheet 111 is T2, and the width of the folded edge of the insulating sheet 111 is H1. from Figure 5a It can be seen from the figure that in the pre-stretched state of the insulating sheet 111, there is obviously a gap T1 between the edge of the insulating sheet 111 and the iron core. If this gap T1 is allowed to exist, the space for installing the coil will be reduced, which will affect the motor. efficiency, it is even difficult to manufacture rotors wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com