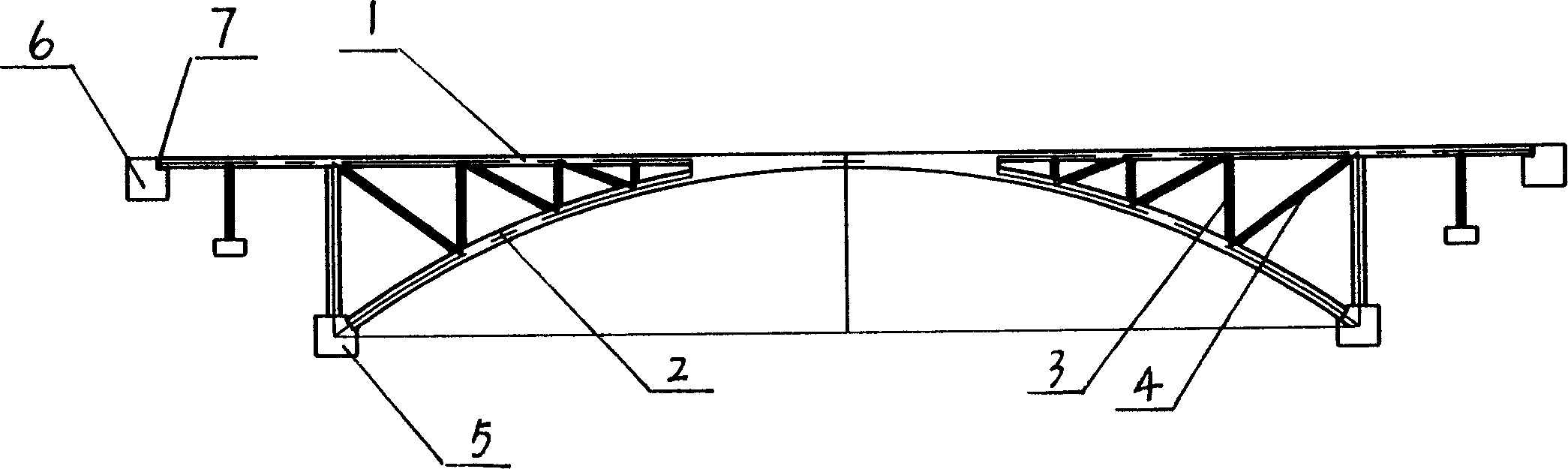

Prestressed concrete continuous truss frame arched bridge

A concrete and prestressed technology, applied in the field of continuous truss arch bridges, can solve the problems of large tensile stress of inclined rods and vertical rods, unfavorable driving comfort, and reduced durability of composite arch bridges, so as to reduce deflection and vibration and improve driving effect. , improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiment of the present invention: the two ends of the lower chord (2) are supported on the abutment (5), the vertical bar (3) is a single vertical bar, and the vertical bar (3) and the inclined bar (4) are supported and connected on the upper chord (1 ) and the lower chord (2), the upper chord (1) is made into a whole continuous rigid-tie beam, the two ends of which are hinged on the abutment anchor wall (6) during construction, the two are separated during use, and the upper chord (1) ) and an expansion joint (7) is left between the abutment anchor wall (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com