Electronic control nailer

A nailing gun and control technology, applied in the field of nailing guns, can solve the problems of uneven nail distance, difficult control, and inability to control the position of the nail distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

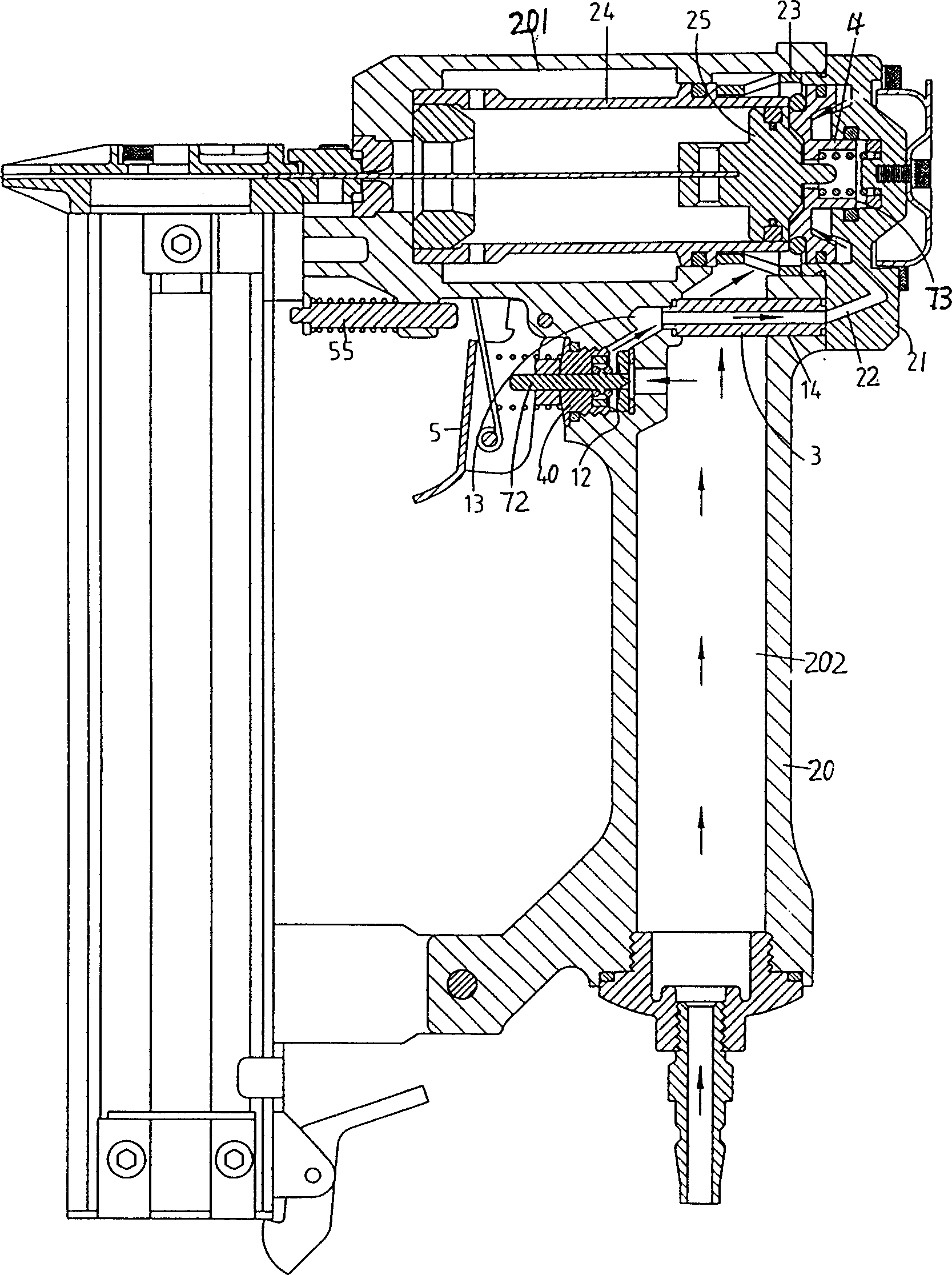

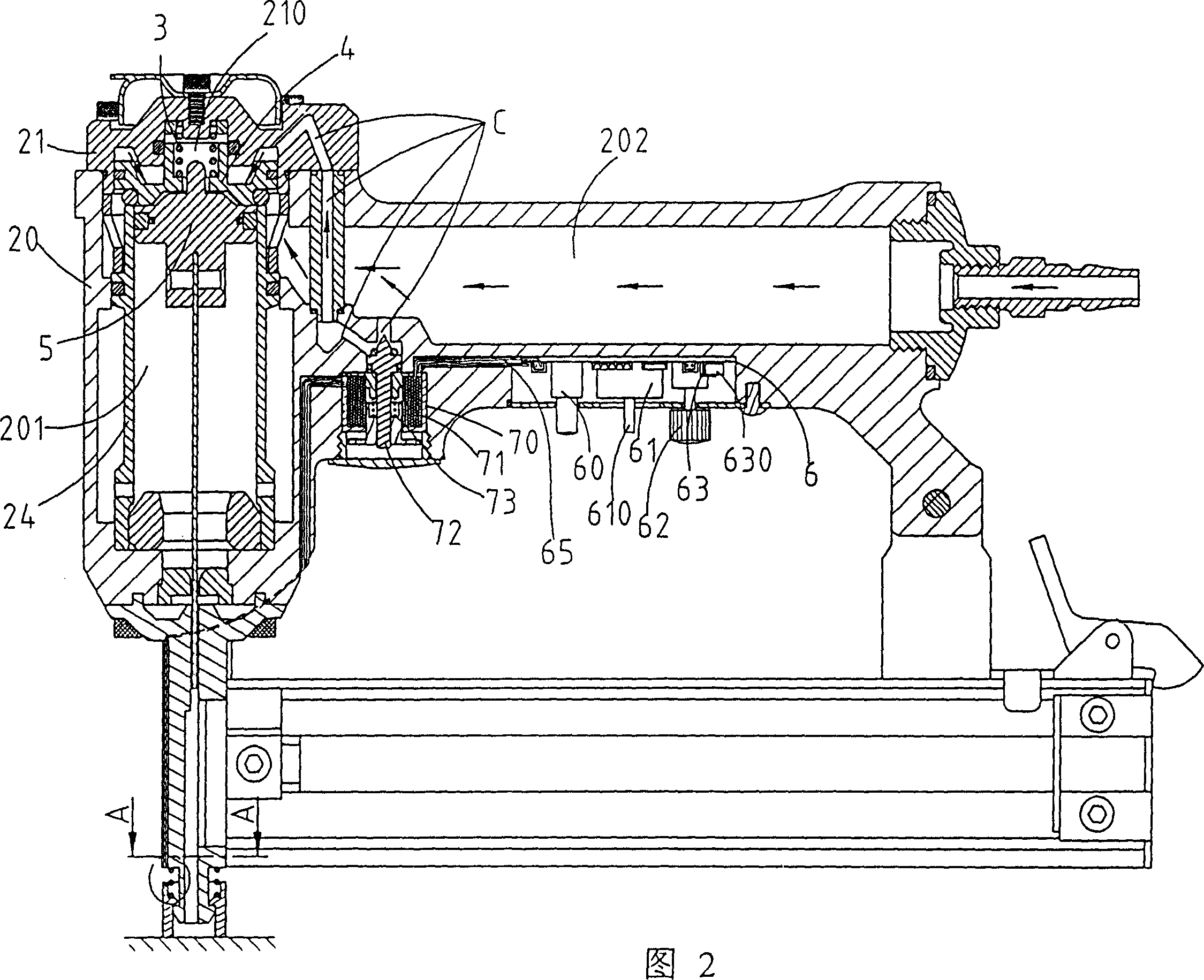

[0027] As shown in Figure 2, image 3 , Figure 4 and Figure 5 As shown, the present invention includes a gun body group 2, wherein the gun body group 2 is composed of a gun body 20 and an upper cover 21, and is placed in the air chamber 201 of the gun body 20 and the accommodating portion 210 of the upper cover 21 The elastic body 3, the top pressure seat 4 and the piston body 5 are housed in sequence; They communicate with the air chamber 201 of the gun body 20 and the accommodating portion 210 of the upper cover 21 respectively, and make one end of the main air passage 202 and one end of the upper air passage C respectively located below and above the top pressure seat 4; The gun body group 2 is respectively provided with a control circuit board 6, a solenoid valve group and a sensing component 8 at appropriate positions, and a loop is formed between the control circuit board 6, the solenoid valve group and the sensing component 8, wherein the control circuit board 6 At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com