Fine stitch array for medicine controlled releasing

A technology of microneedle array and drug controlled release, applied in the field of drug controlled release microneedle array, can solve the problems of easily causing infection and pain, and achieve the effect of reducing the probability of infection, sharp needles, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

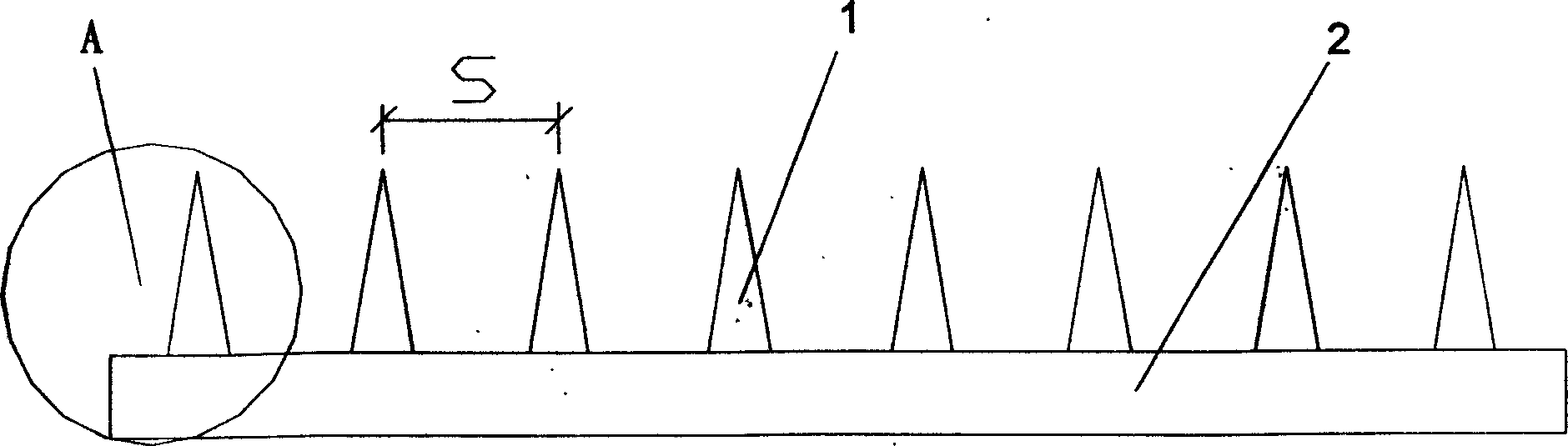

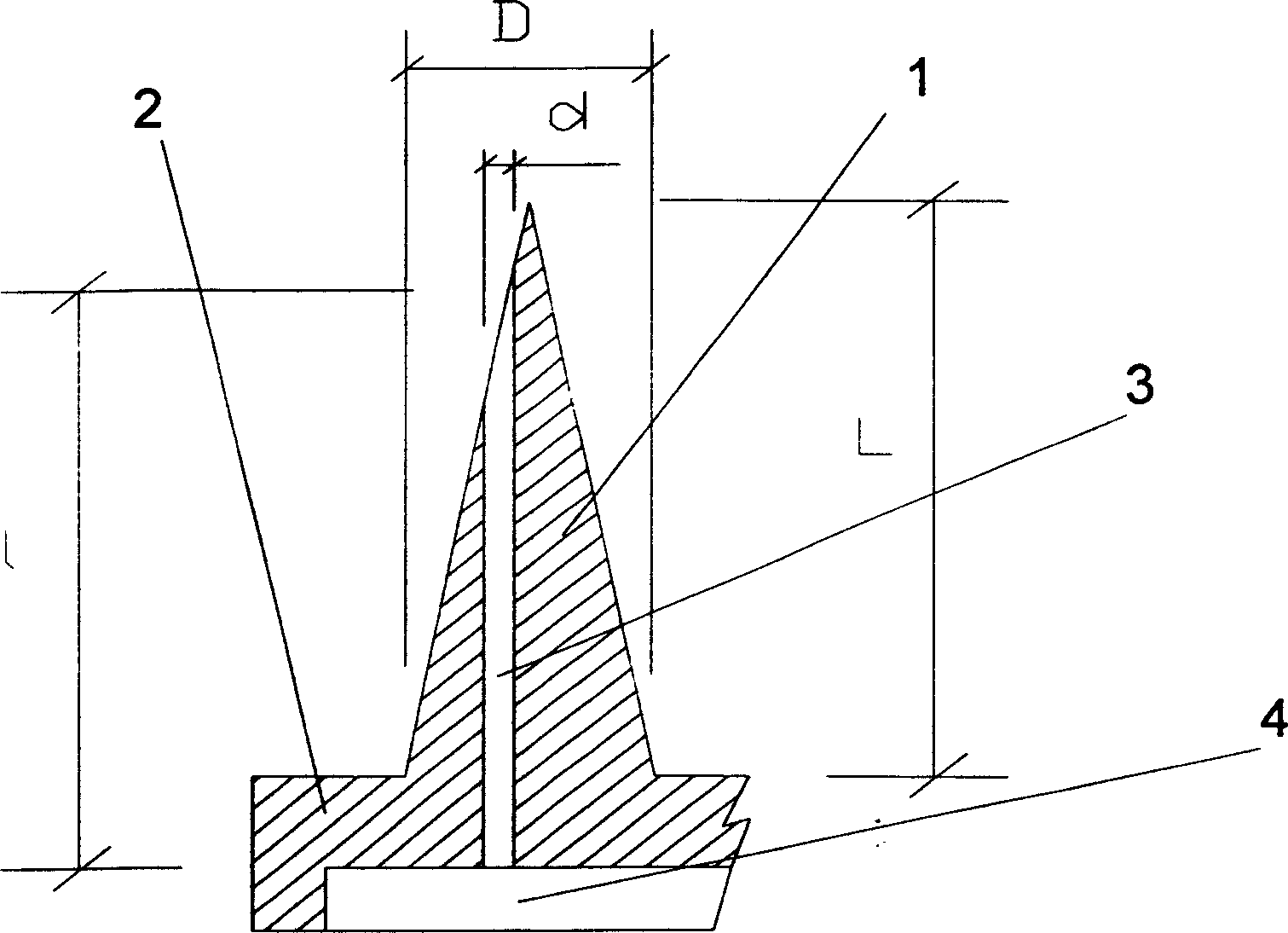

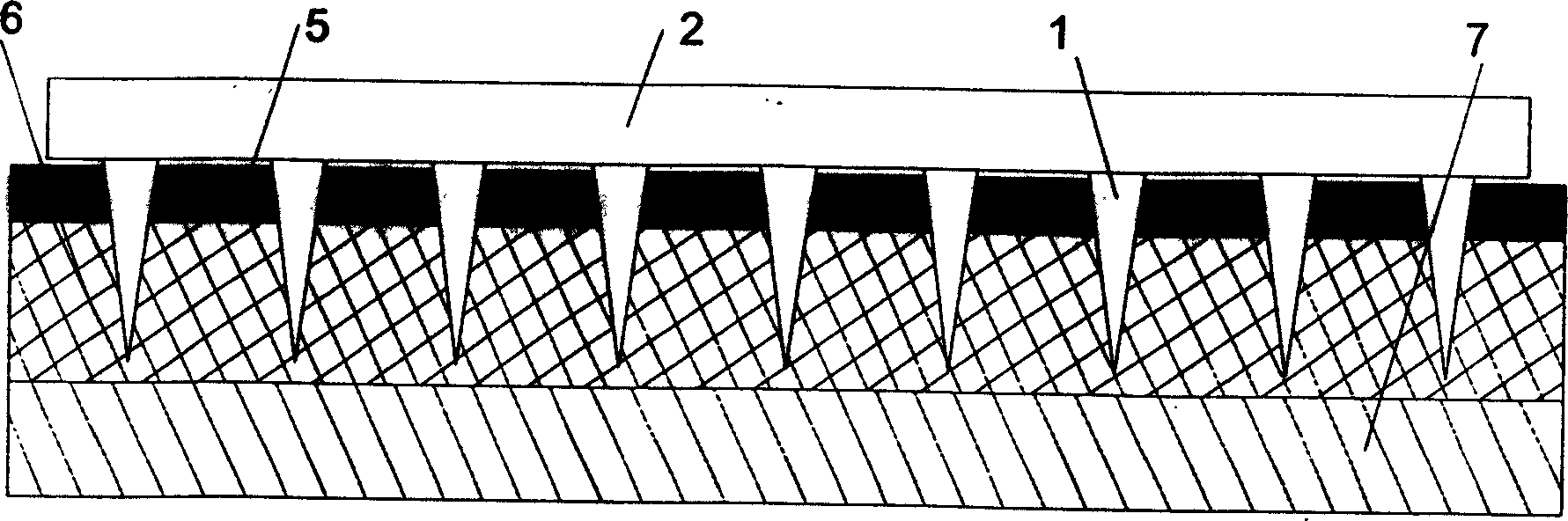

[0015] Such as figure 1 , figure 2 Shown, the present invention it comprises:

[0016] A microneedle array consisting of a group of equidistantly distributed conical hollow microneedles 1 is formed on the substrate 2 with grooves 4 on the bottom surface. The pinholes of the microneedles are on one side of the needle head, and the microneedle pinholes are connected to the grooves 4 on the bottom surface of the substrate. Pass.

[0017] The length L of the conical hollow microneedle 1 is 100-150 μm, the outer diameter D of the cone bottom is 50-80 μm, the inner diameter d of the microneedle pinhole is 10-40 μm, and the pinhole length 1 of the microneedle is 80-100 μm, The spacing S between one microneedle is 100 to 120 μm.

[0018] The present invention is used for the processing method of a kind of microneedle array of drug controlled release:

[0019] 1) Oxidize the silicon wafer to form a layer of silicon dioxide oxide film, then clean and dry the silicon wafer;

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com