Technique of maufacturing electrocast refractories through bubbling method

A refractory material and production process technology, applied in the field of refractory materials, can solve problems such as explosion, achieve the effects of uniform charge composition, reduce power consumption per ton, and increase the number of reaction contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

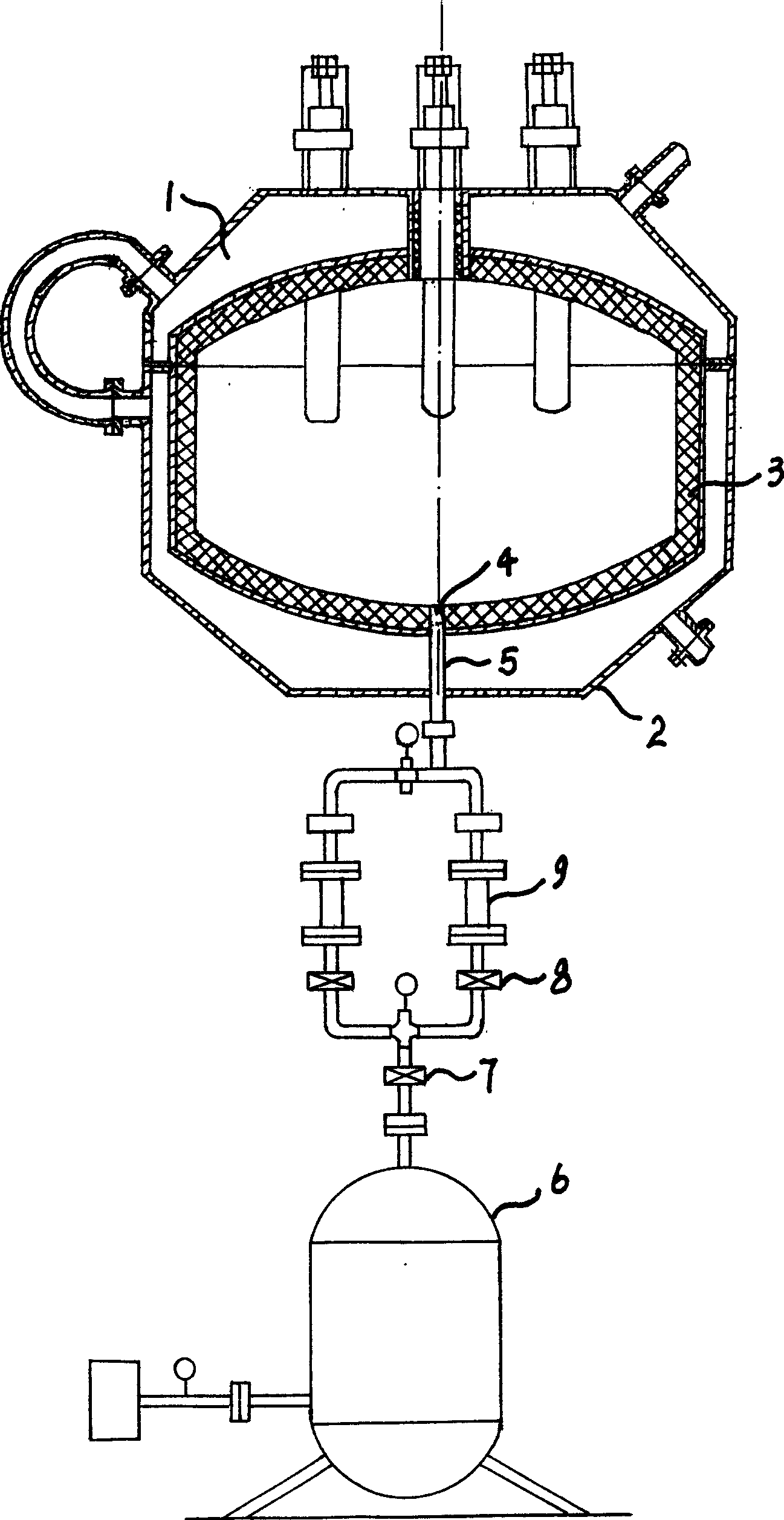

[0014] As shown in the figure, the method of the present invention is to mix the raw materials and fluxes for producing fused refractories and then add them into the electric melting furnace 1; 3 of the through hole 4; in the through hole 4, an air guide pipe 5 is arranged, and the air guide pipe 5 communicates with the compressed air storage tank 6 arranged outside the furnace body; Valve 7, pressure reducing valve 8, gas flow meter 9; during smelting, open the inlet valve 7 at the same time as the arc strikes to slowly input compressed air from the bottom of the furnace cavity into the cavity of the input electric melting furnace 1 from the air guide pipe 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com