Rolling bearing

A rolling bearing and bearing steel technology, applied in the field of rolling bearings, can solve the problems of not focusing on the rolling life, the surface structure becomes coarse, the whole grain becomes larger, etc., and the effect of use is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

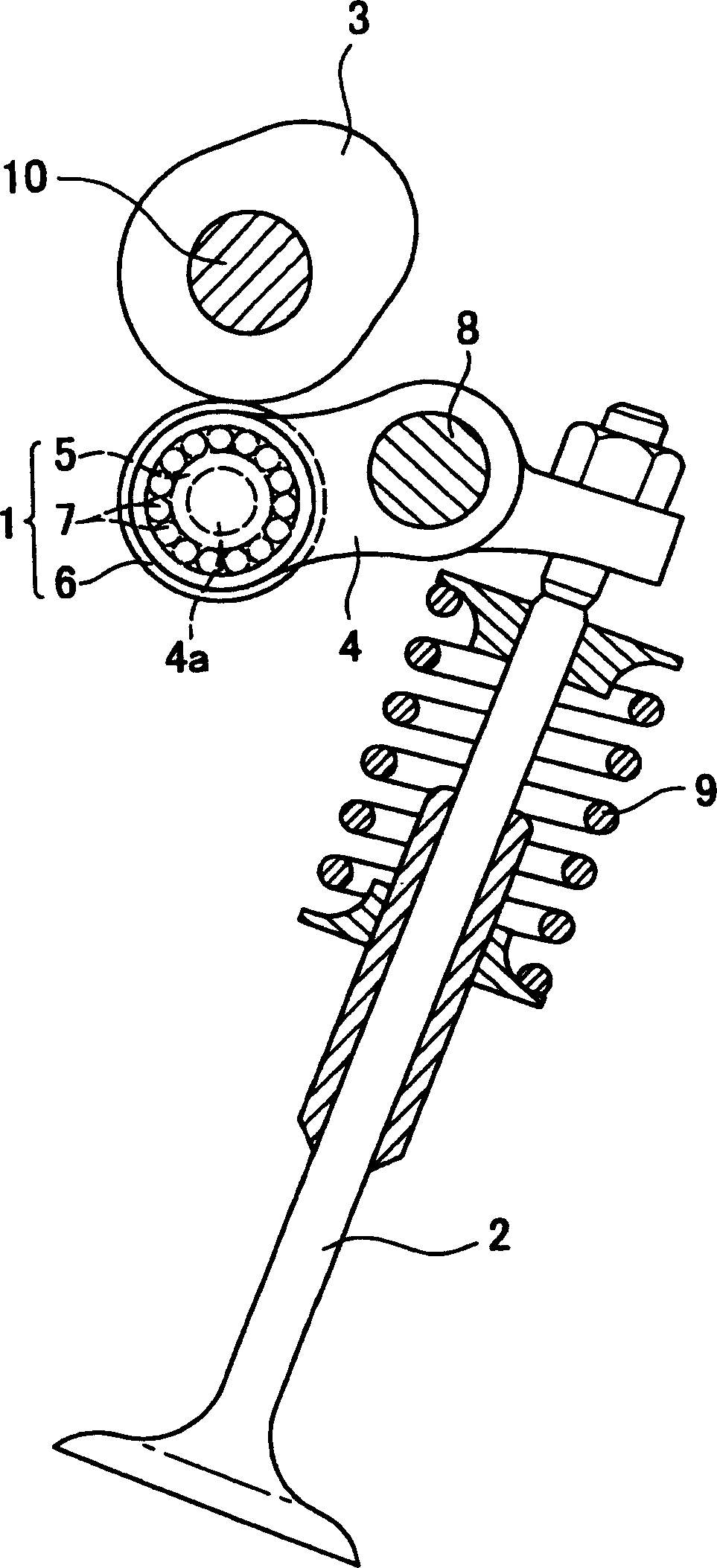

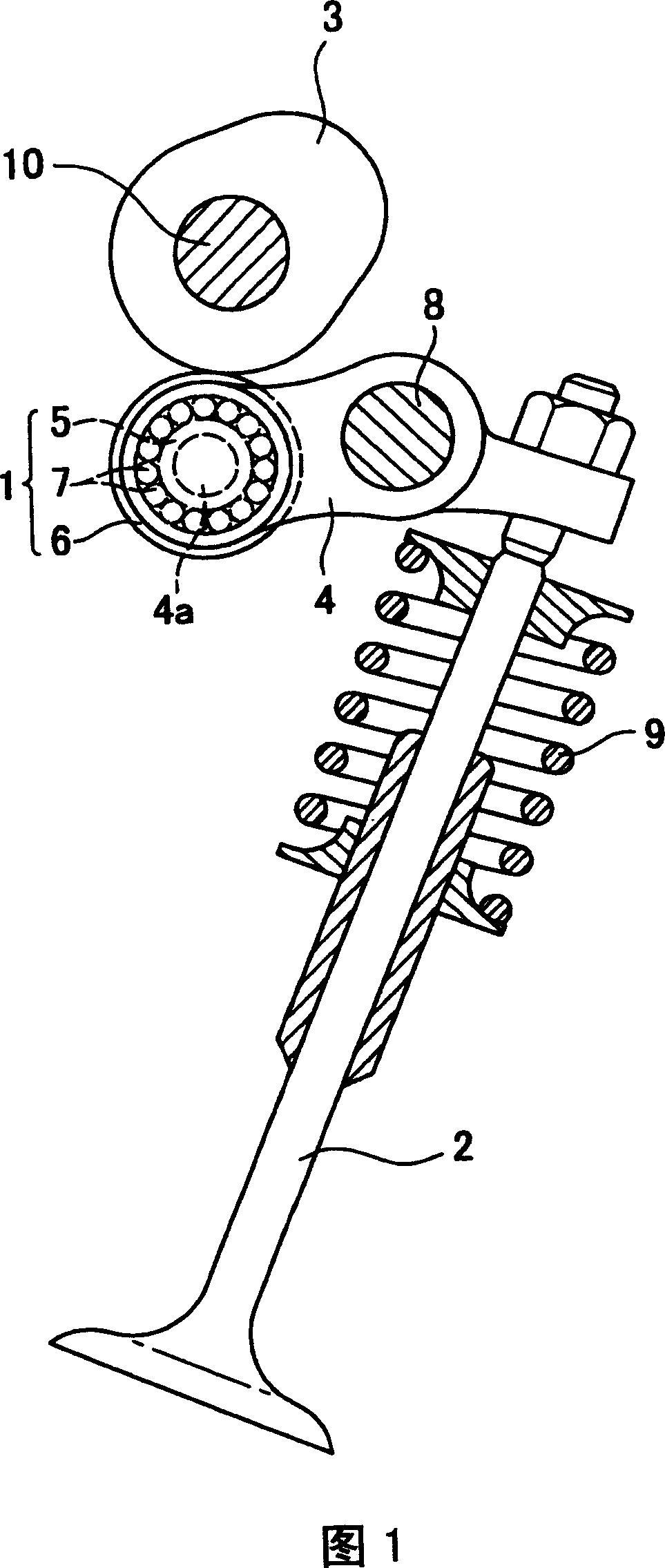

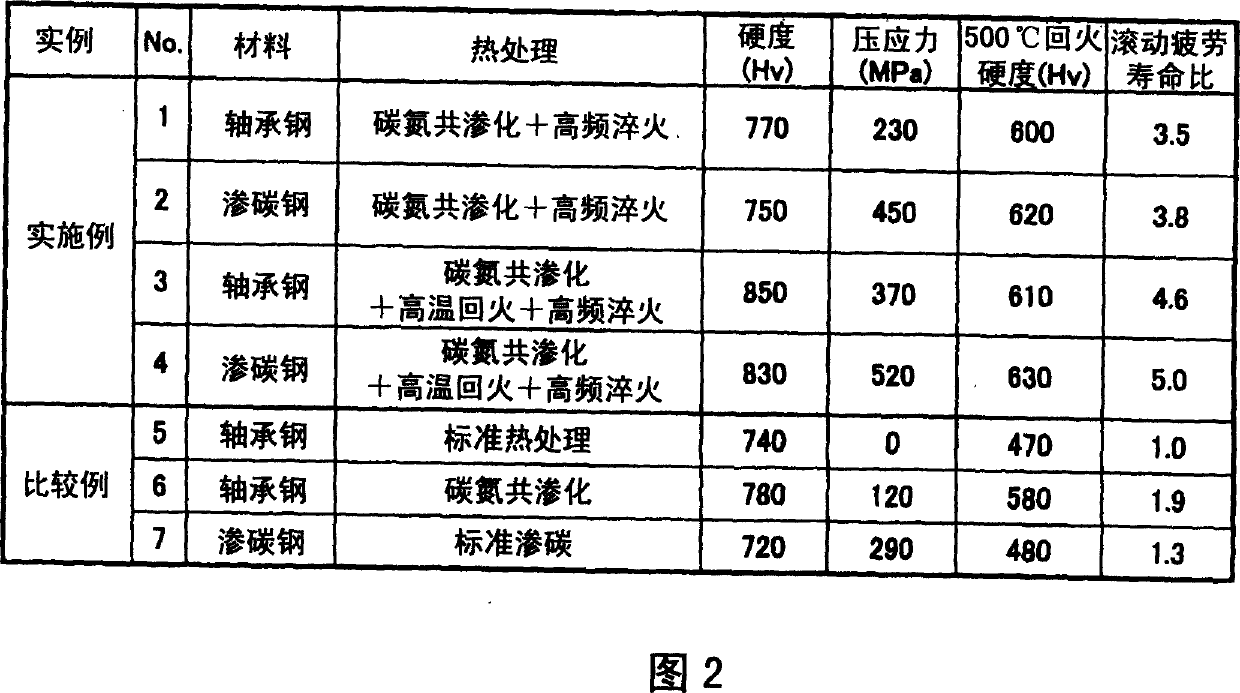

[0021] Next, an embodiment of the present invention will be described based on FIGS. 1 to 3 . FIG. 1 shows a state in which a rolling bearing 1 of the embodiment is assembled in a rocker arm 4 disposed between an automobile engine valve 2 and a cam 3 for opening and closing the valve. The rolling bearing 1 is composed of an inner ring 5 fitted to a fixed shaft 4a of the rocker arm 4, an outer ring 6 facing the cam 3, and a plurality of rollers 7 arranged without a cage between the two rolling rings 5 and 6. constitute. On the one hand, the central part of the rocker arm 4 is fixed on the freely rotatable rocker arm shaft 8, and one end of the rocker arm 4 is connected to the valve 2, and the valve spring 9 is used to force the rocker arm 4 to the bottom of the drawing, and is installed on the rocker arm 4. The outer peripheral surface of the outer ring 6 of the bearing 1 on the other end side of the arm is always pressed against the cam 3 . Therefore, once the cam 3 rotate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com