Double deck elevator

A technology of double-deck elevators and target floors, which is used in elevators, agriculture, elevators and other directions in buildings, which can solve the problems of increased speed changes, large speed changes, and increased equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

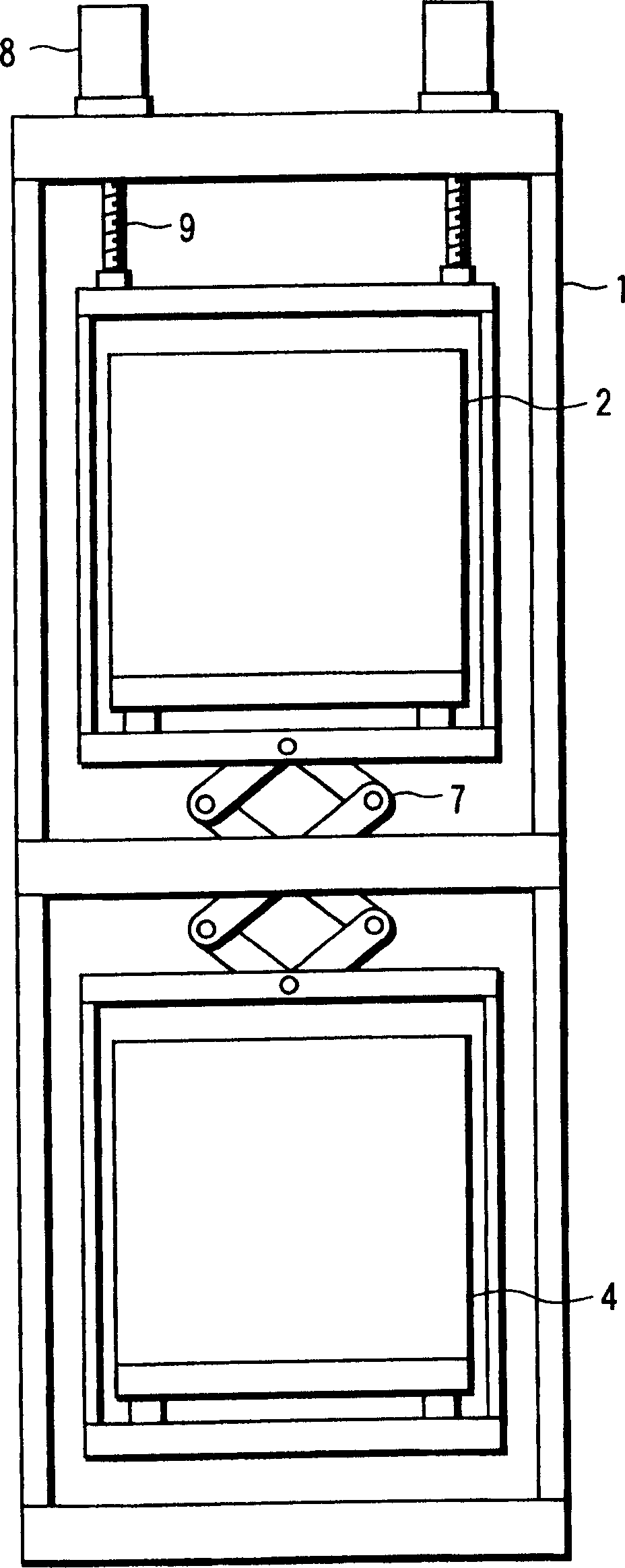

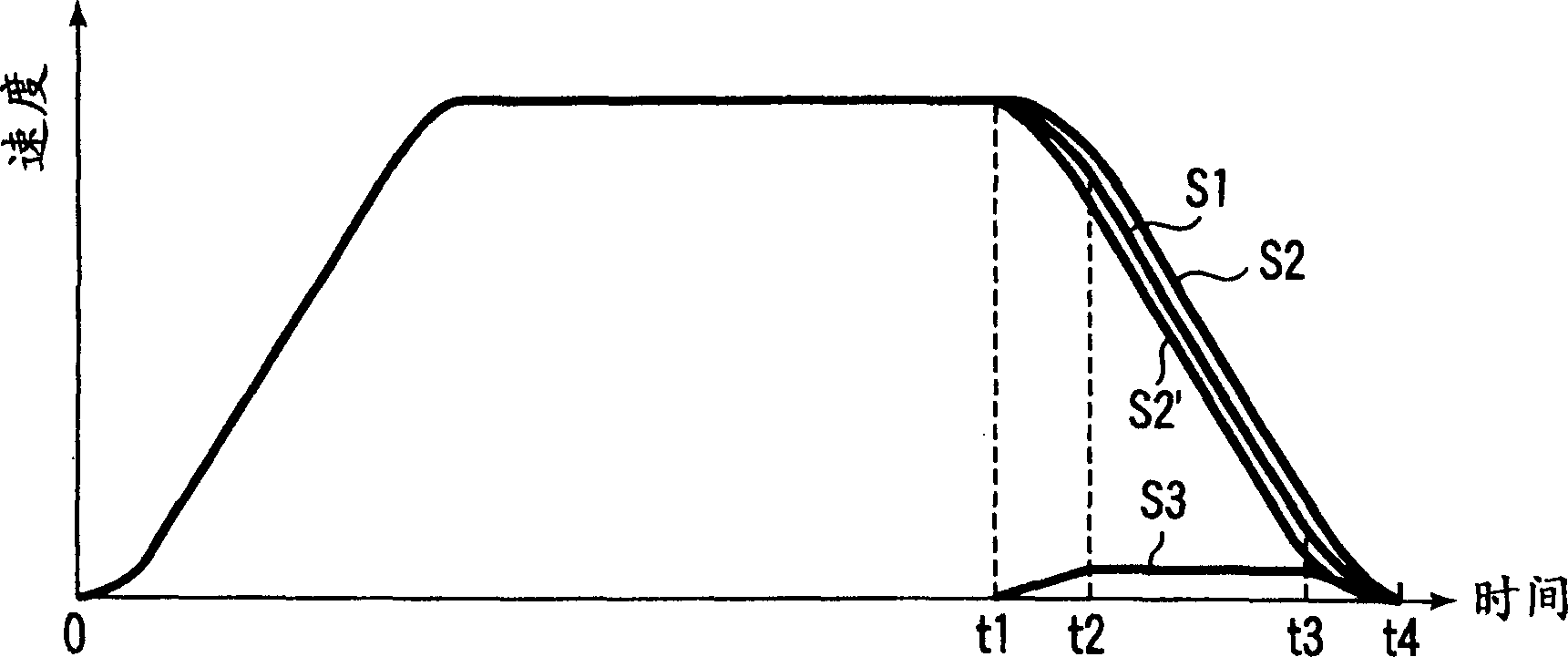

[0022] image 3 is a schematic diagram showing the structure of a double-deck elevator according to the first embodiment of the present invention. The elevator includes a car frame 1 and upper and lower cars 2 and 4 arranged in the car frame 1 .

[0023] The upper car 2 and the lower car 4 are installed on the car frame 1 , and either or both of the upper car 2 and the lower car 4 have a car driving device 10 . For example, in image 3 Among them, the lower car 4 has a car drive 10 . The car drive 10 includes a guide roller 5 and an actuator 6 . If the actuator 6 of the car driving device 10 is driven, the lower car 4 is lifted / lowered by the guide roller 5, thereby changing the distance between the upper car 2 and the lower car 4 . Hereinafter, the car driven by this car driving device 10 is referred to as a "moving car". According to the present invention, the structure of the car driving device 10 is not limited to any specific structure.

[0024] The car frame 1 on w...

no. 2 example

[0069] Next, a second embodiment of the present invention will be described.

[0070] Figure 7 is a schematic diagram showing the structure of a double-deck elevator according to the second embodiment of the present invention. In this second embodiment, with the structure of the first embodiment ( image 3 ) In comparison, the car position control device 16 and the memory 17 are included in the winch control device 15 .

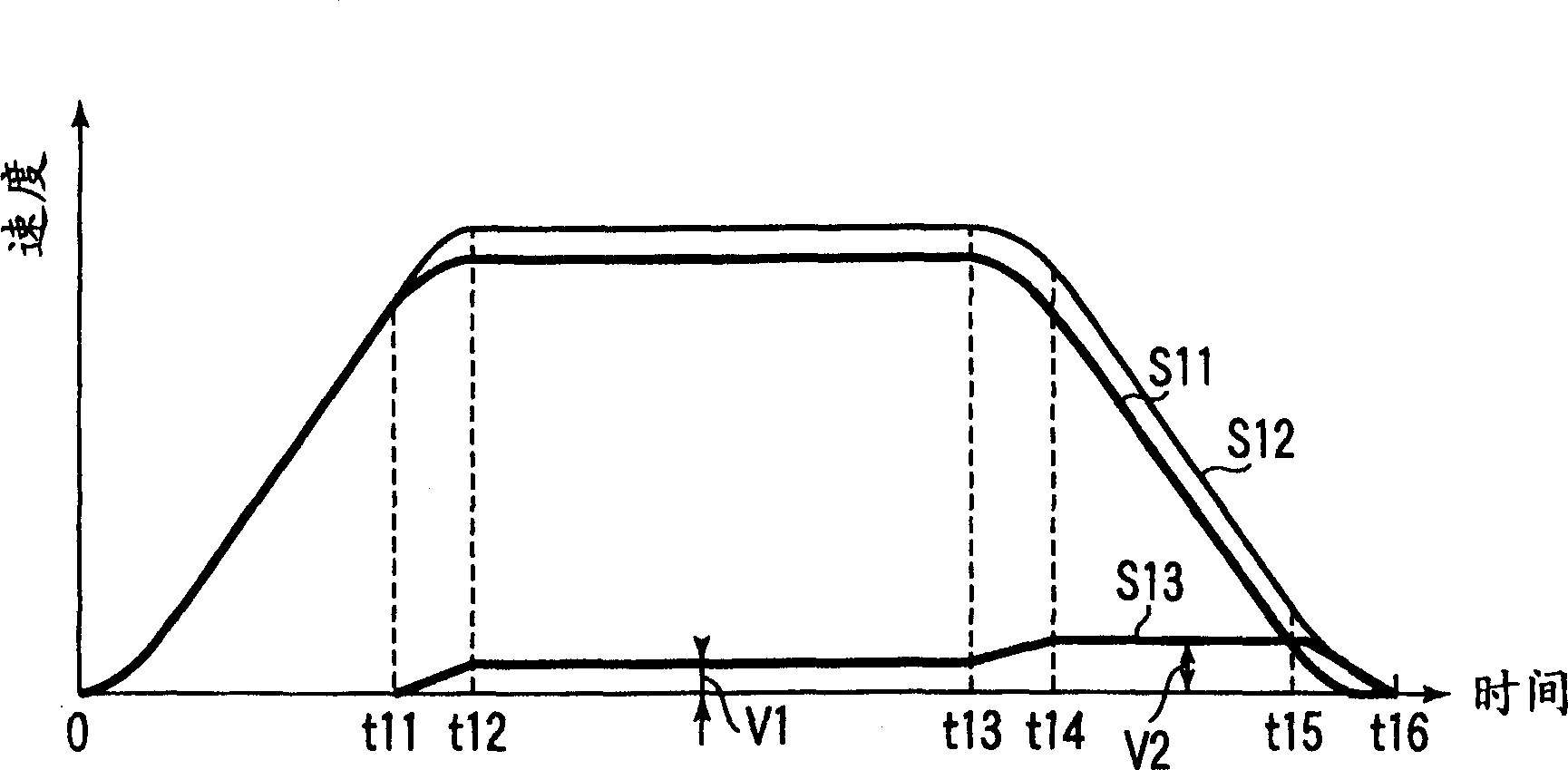

[0071] In other words, the winch control device 15 includes a correcting car position control device 16 and a memory 17 , and the winch control device 15 sends a control command to the winch machine 13 and a control command to the car driving device 10 . The memory 17 stores data on the velocities V1 and V2 calculated from the inter-layer information of each layer or its pre-stored inter-layer information.

[0072] With this configuration, the car drive device 10 is controlled as follows, similarly to the first embodiment. The hoist control device 15 sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com