Charging power generator set

A generator set and generator technology, applied in the direction of electric components, windings, electrical components, etc., can solve problems such as low efficiency, heavy weight, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments are described in detail below in conjunction with the accompanying drawings.

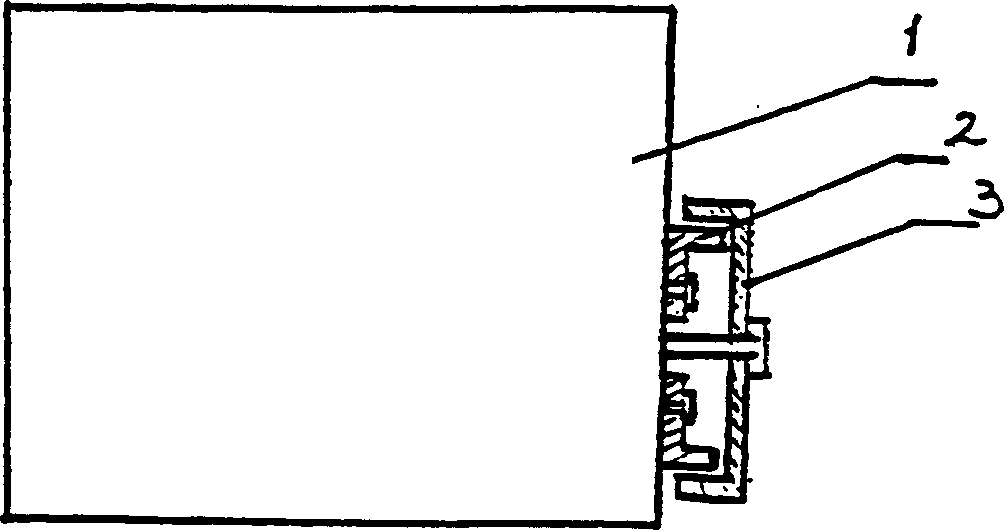

[0012] Fig. 1 is a schematic diagram of the connection between the generator set and the power machine of the present invention. The generator set includes a power machine 1, a generator rotor 3 directly connected to the power machine shaft, and a generator stator 2 fixed on the power machine casing. That is, the generator set of the present invention is a machine in which the power machine and the generator are integrated. The power machine is a gasoline engine or a diesel engine.

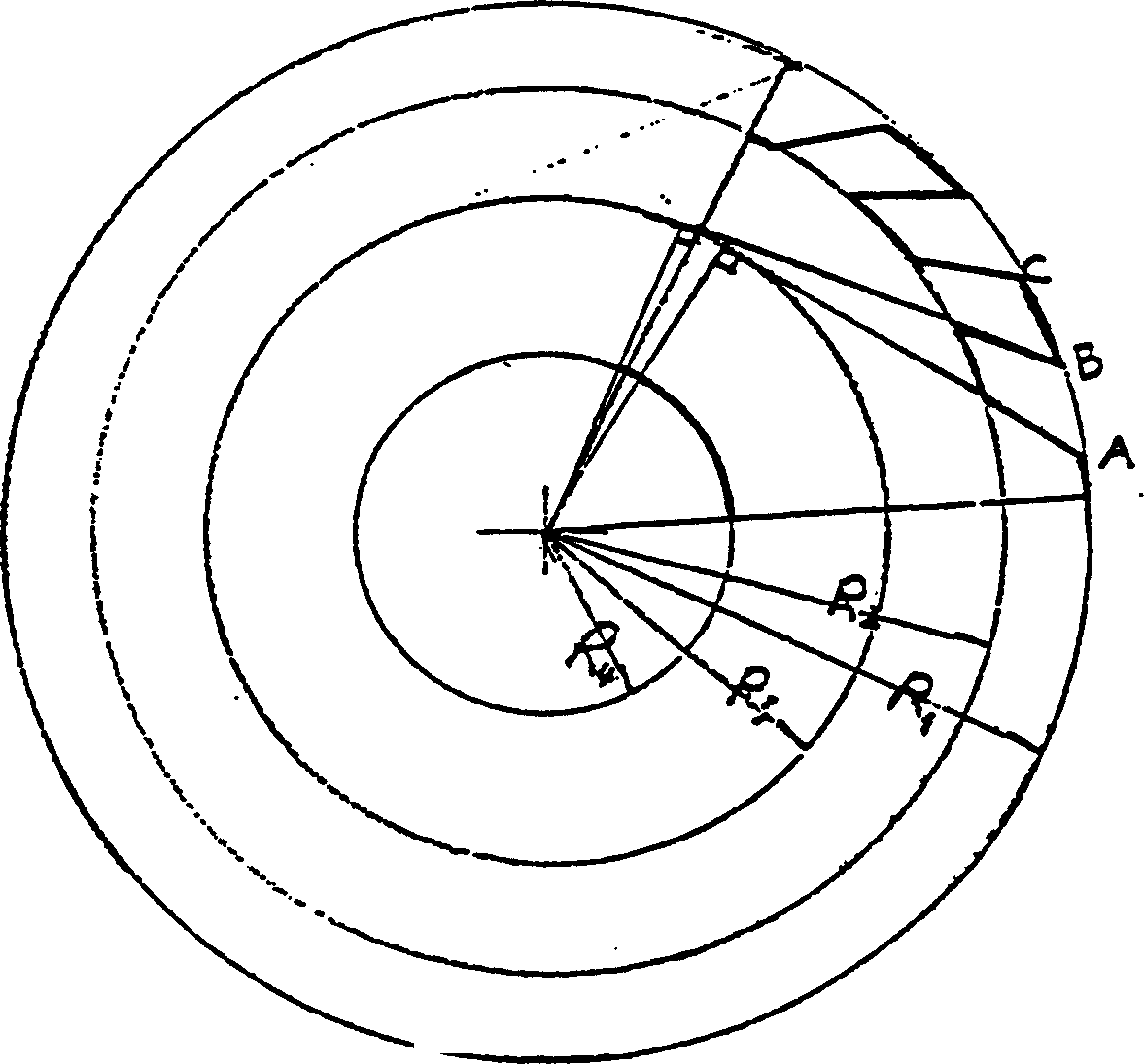

[0013] The power of the generator in this example is 2.7KW, 56 poles, 112 slots, and the generator speed is 3000rpm. It is an external rotor generator, but it is not necessary.

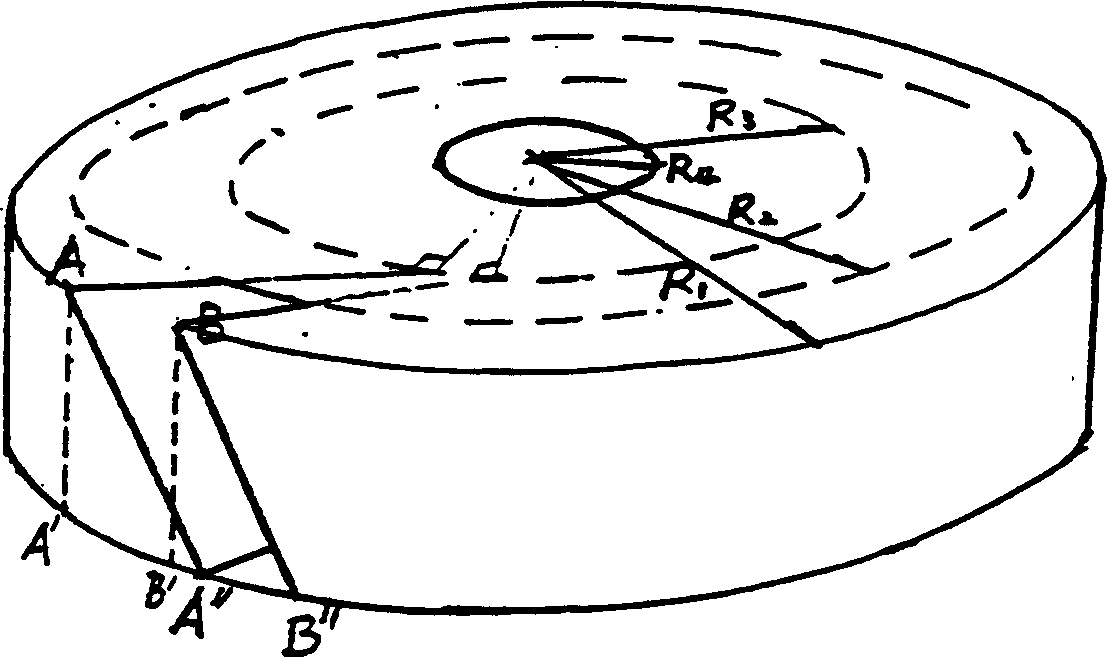

[0014] The stator 2 is a cylinder made of silicon steel sheets, and a plurality of grooves are arranged in its outer circumference. Figure 2 is a schematic diagram of the structure formed by the grooves, R 1 is the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com