Electric circuit breaker

A technology for circuit breakers and circuits, which is applied to circuits, circuit breaker parts, electric switches, etc., and can solve problems such as slow movement of arc ends, inability of arc points to travel continuously, and inability to obtain high-speed interruption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

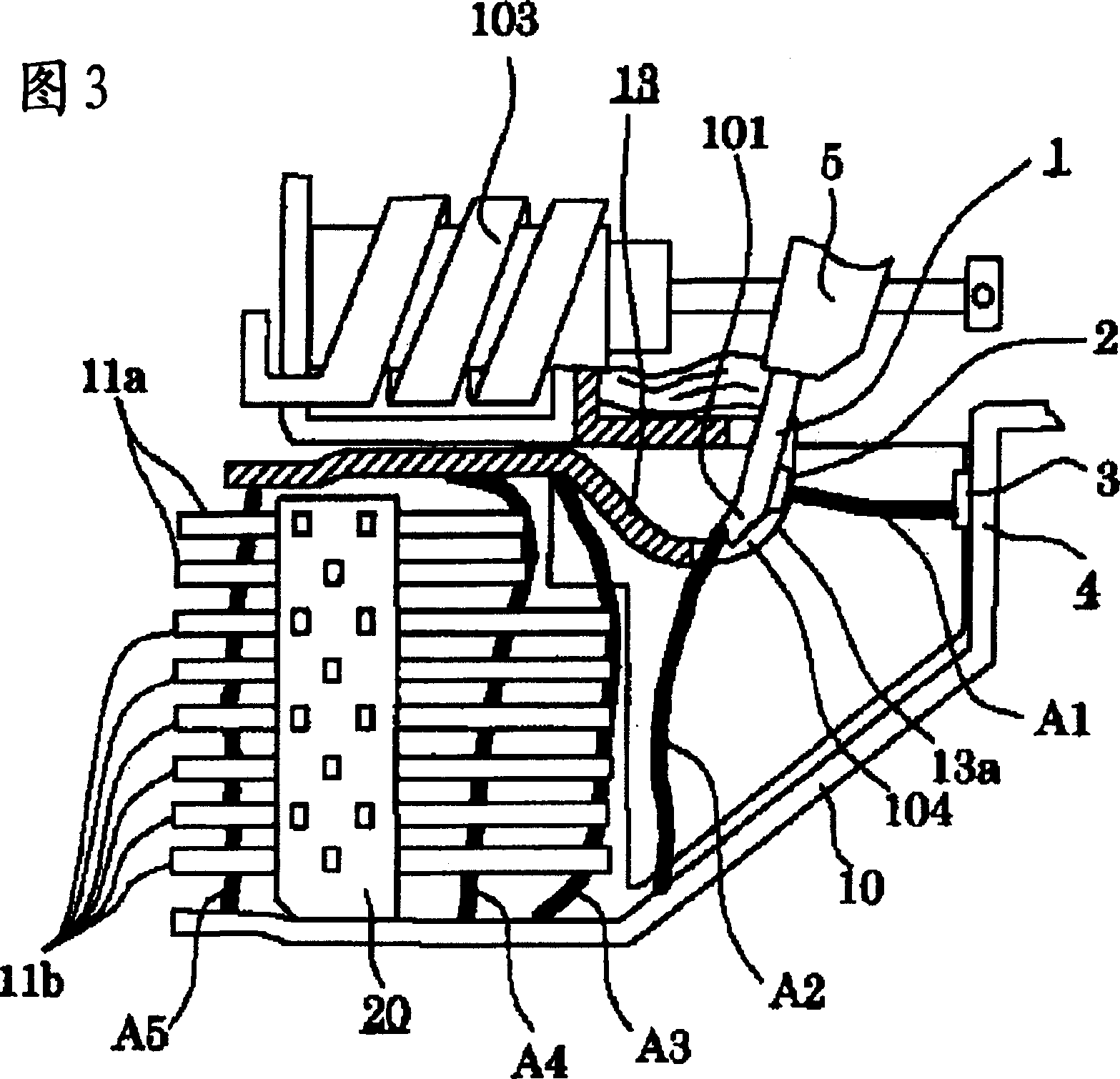

[0030] Figure 1~ Figure 4 It is a figure for explaining the circuit breaker of Example 1 of this invention, More specifically, FIG. figure 2 It is an enlarged perspective view showing the arc guide on the side of the movable adapter, and FIG. 3 is a partial cross-sectional view of the main part for schematically showing the behavior of the arc during the breaking operation, Figure 4 It is a plan view of the arc extinguishing plate viewed from the arc guide on the side of the movable adapter.

[0031] As shown in FIG. 1 , generally in such a circuit breaker, it is provided in a frame body 202 made of insulators: a pair of terminals 200 and 201 (201 not shown) connected to an external circuit; The adapter 4; the movable contact 2 that is connected and separated from the fixed contact 3, and the movable adapter 1 forming an adapter pair with the fixed adapter 4; the switch mechanism 5 that drives the movable adapter 1; responds to the overcurrent to make the The switch mecha...

Embodiment 2

[0052] Figure 5 It is a figure for explaining the circuit breaker of Example 2 of this invention, More specifically, it is a plan view which looked at the arc-extinguishing plate from the arc guide side of a movable adapter side.

[0053] Compared with the circuit breaker of Embodiment 1, the circuit breaker of this embodiment has different shapes of the ends of the contacts 2 and 3 of the arc extinguishing plate 11a near the arc guide member on the side slower than the arc extinguishing device 20, Other structures are the same as in Embodiment 1. Therefore, points different from Example 1 will be mainly described below.

[0054] In this example, if Figure 5 As shown, the other arc extinguishing plate 11b is configured in the same plate shape with a wedge-shaped cutout as in Embodiment 1, and the arc extinguishing plate 11a near the arc guide 13 on the side of the movable adapter is configured to have a larger cutout than the other arc extinguishing plate 11b. The width (...

Embodiment 3

[0060] Figure 6 It is FIG. 3 for explaining Example 3 of the present invention, and more specifically, it is a partial cross-sectional view of main parts.

[0061] Compared with the circuit breaker of the first embodiment, the circuit breaker of this embodiment differs in the structure of the arc guide member on the side of the movable adapter, and the other structures are the same as those of the first embodiment. Therefore, points different from Example 1 will be mainly described below.

[0062] In Embodiment 1, in order to shorten the time required for commutation from the angular portion 101 of the arc point on the side of the movable joint 1 to the arc guide 13 on the side of the movable joint, the arc is guided on the side of the movable joint. The member 13 is provided with a protruding portion 13a that protrudes toward the fixed contact 3 side and has a slit 104 through which a part of the movable adapter 1 passes when the movable contact 2 leaves, but in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com