Magnetorheological continuously variable transmission

A continuously variable transmission, magnetorheological technology, applied in transmissions, friction transmissions, belts/chains/gears, etc., can solve the problems of high working voltage, insufficient performance, and low shear yield stress of electrorheological fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

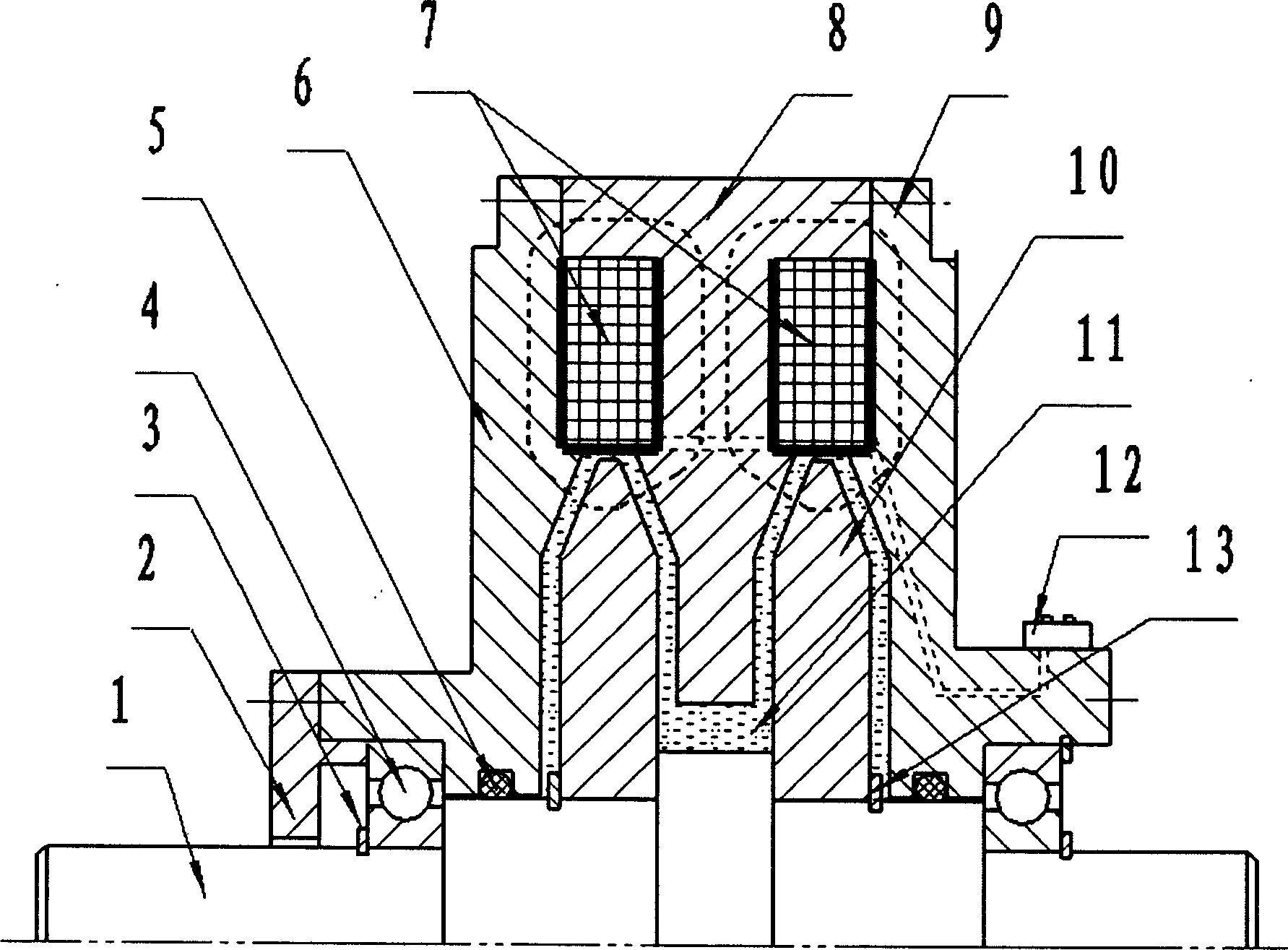

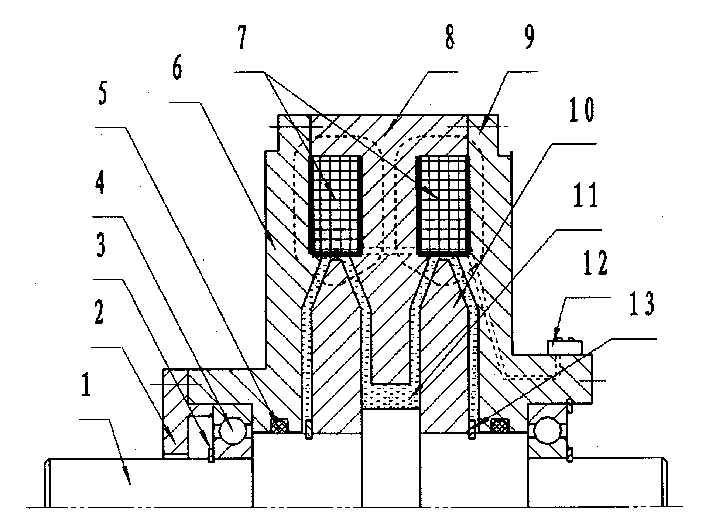

[0014] The input torque and rotational speed pass through the input shaft 1, the inner rotor disk 10, the torque is transmitted through the working medium 11 under the excitation magnetic field of the coil 5, and the load torque and rotational speed are output through the outer rotors 6, 8, 9. The right end of the outer rotor can be Connect to output connection parts such as standard flanges.

[0015] The input shaft 1 and two inner rotor discs 10 are fixedly connected together, the coil 7 is fixed in the outer rotor, and its excitation current is adjusted by an external adjustable DC power supply through a sliding brush 12 . The four radial slopes of the two inner rotor disks 10 and the inner surfaces of the outer rotor yokes 6, 8, and 9 form two V-shaped working gaps, and the magnetorheological fluid 11 fills the entire working chamber, and the seal on the outer rotor Ring 5 is sealed. The two inner rotor disks 10 are positioned axially by the middle shoulder of the shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com