Driving Speed-changing device

A technology of speed change mechanism and transmission parts, applied in transmission devices, friction transmission devices, mechanical equipment, etc., can solve the problems of short service life, high noise, easy wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

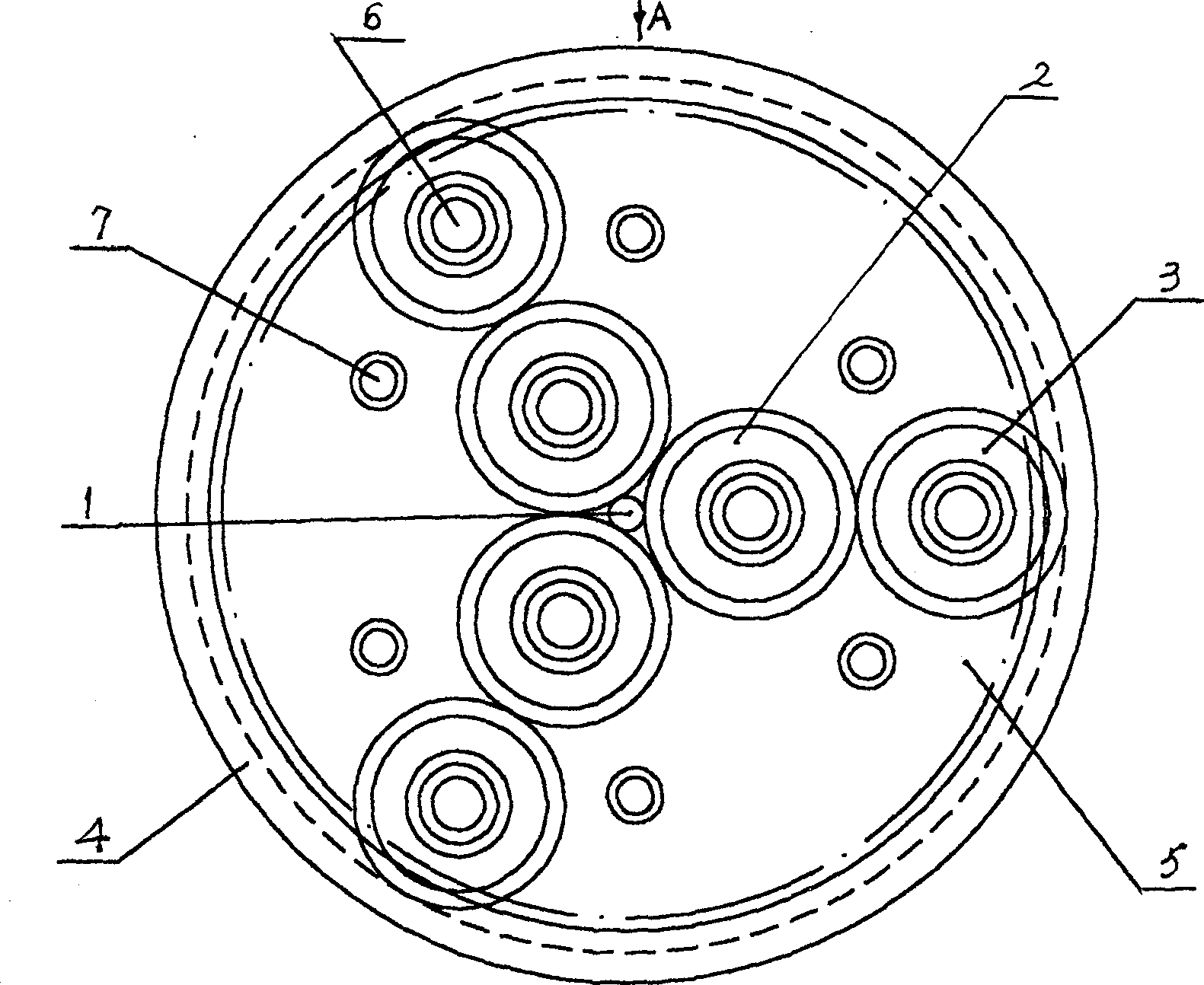

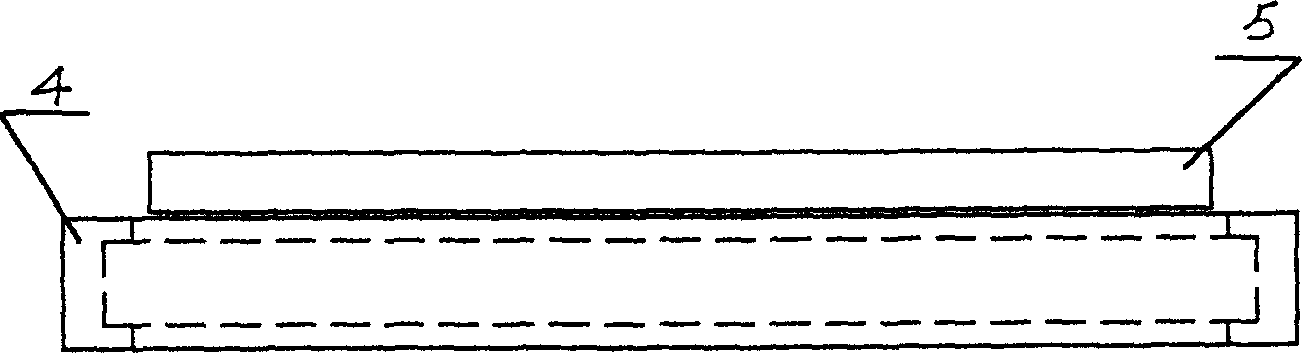

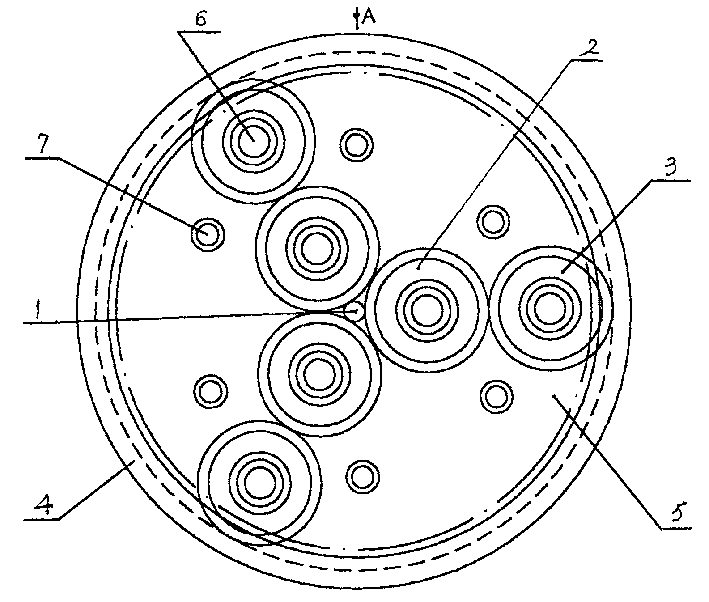

[0006] The invention discloses a transmission and speed change mechanism, which is composed of a drive shaft (drive shaft) driven by power (mainly driven by a motor) and a transmission component matched with the drive shaft. The main feature is that the bearing is used as the transmission component. Bearing pin 6 is installed on the support 5, and support 5 has the fixing screw hole 7 that connects in addition, and the outer side of bearing matches with bearing sleeve 4, and bearing sleeve 4 is connected with working equipment. The drive shaft 1 is in friction fit with two evenly distributed bearings or three bearings 2, the best example is figure 1 Shown are three bearings, and the outer ring bearing 3 can be matched with the inner ring bearing 2 directly matched with the drive shaft 1, and the outer ring bearing 3 and the bearing sleeve 4 are frictionally matched, and the inner and outer ring bearings 2, 3 is installed on the bracket 5.

[0007] The transmission speed chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com