High power microwave plasma torch

A microwave plasma, high-power technology, applied in the field of ion torch, can solve the problems of inconvenient adjustment, low power level, complex excitation and maintenance mechanism, etc., and achieve the effect of simple mechanism, large incident power and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

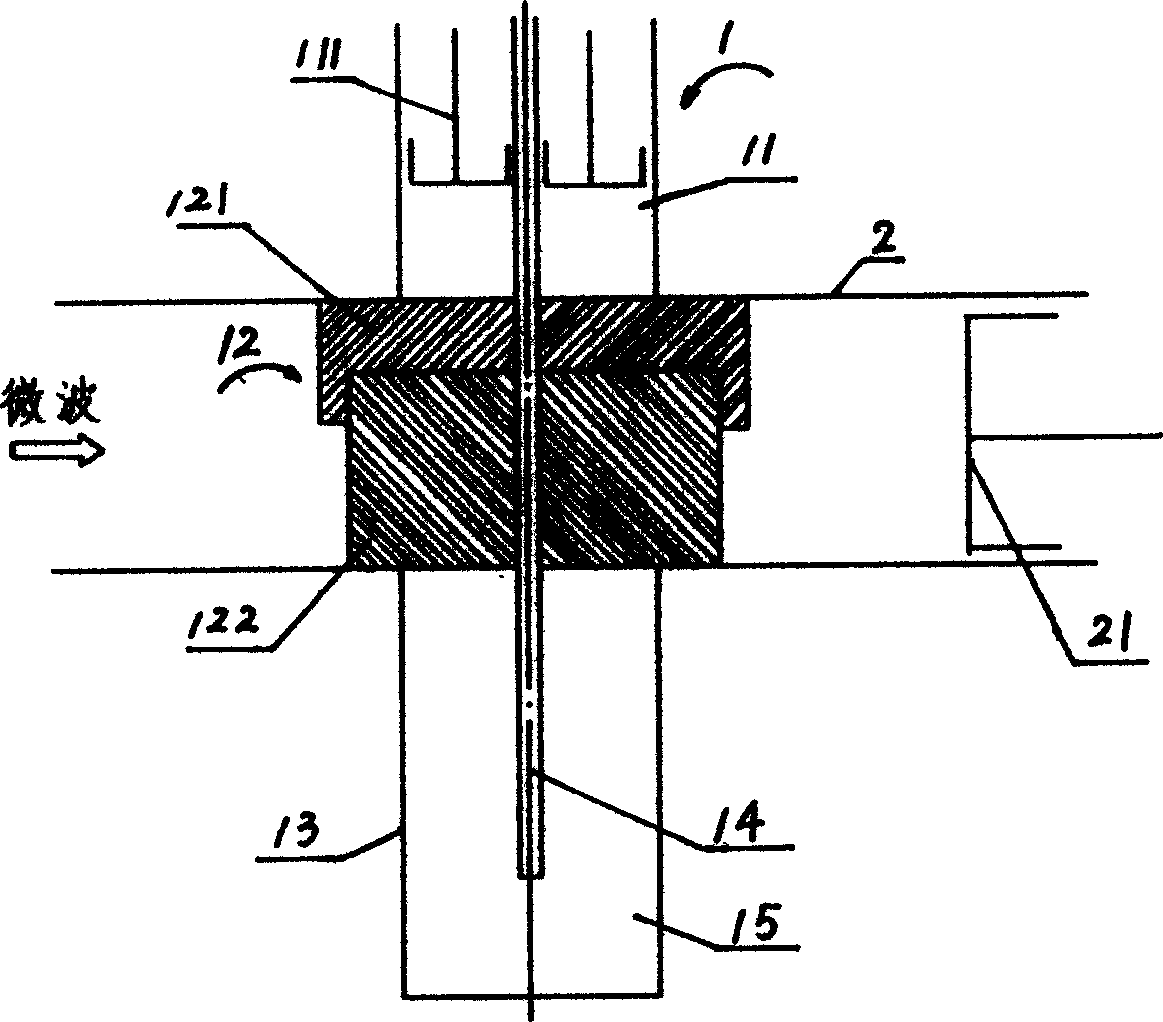

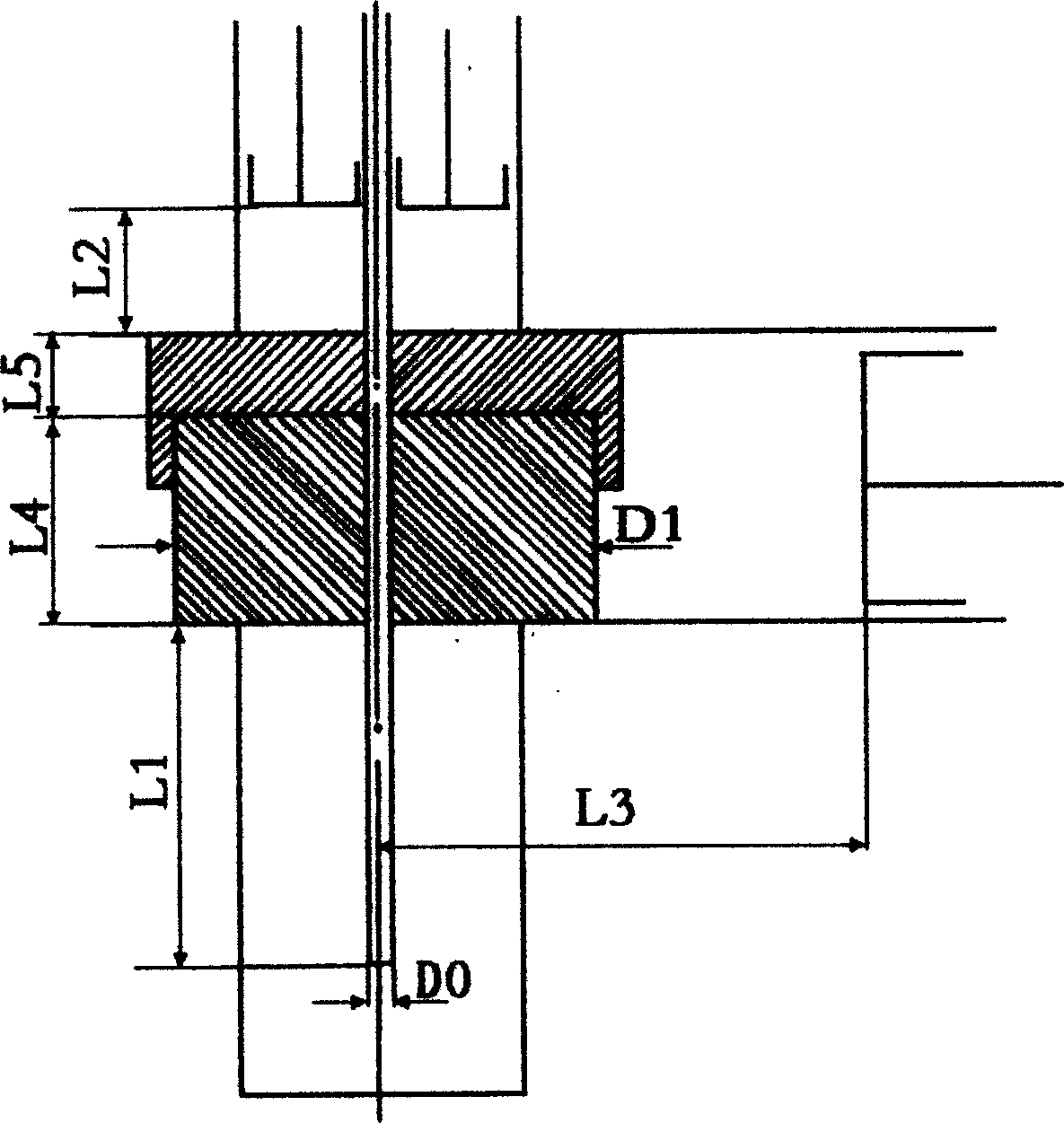

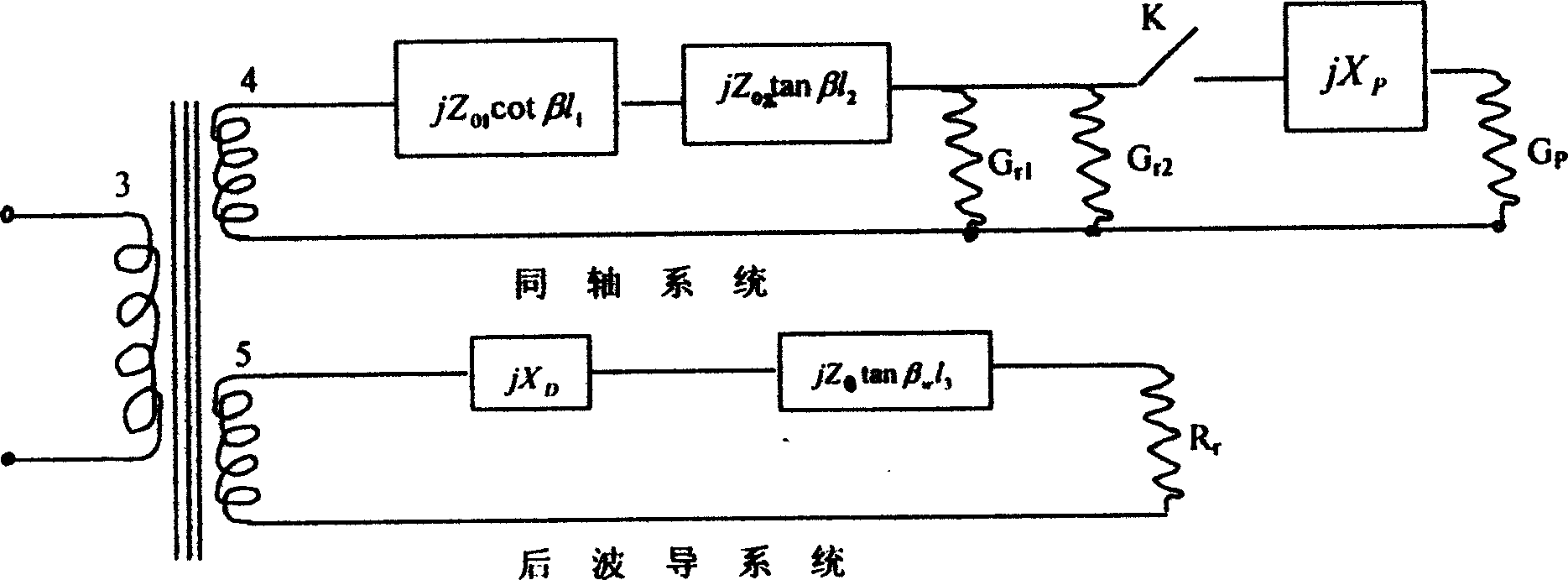

[0020] The present invention relates to a high-power, high-efficiency microwave plasma excitation device, figure 1It is a structural schematic diagram of the device, including a tunable coaxial resonant cavity 1, a rectangular waveguide 2, and a waveguide / coaxial conversion device 12 is arranged inside the rectangular waveguide 2, and the waveguide / coaxial conversion device 12 is a door twist block 121 and The door twist structure of the dielectric single wire 122 buckled up and down, the waveguide / coaxial conversion device 12 is closely connected with the upper and lower surfaces of the rectangular waveguide 2, and the tunable coaxial resonant cavity 1 is located on the upper and lower sides of the waveguide 2 and connected to the The coaxial upper cavity 11, the lower cavity 15, and the waveguide / coaxial conversion device 12 are jointly formed by the coaxial / coaxial conversion device 12. The upper and lower chambers are coaxial lines formed by the outer conductor 13 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com