Elevator overspeed protection apparatus

A kind of protective equipment and elevator technology, which is applied in the direction of elevators, transportation and packaging, etc. It can solve the problems of inconvenient handling, changes in the displacement of the flat block 17, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

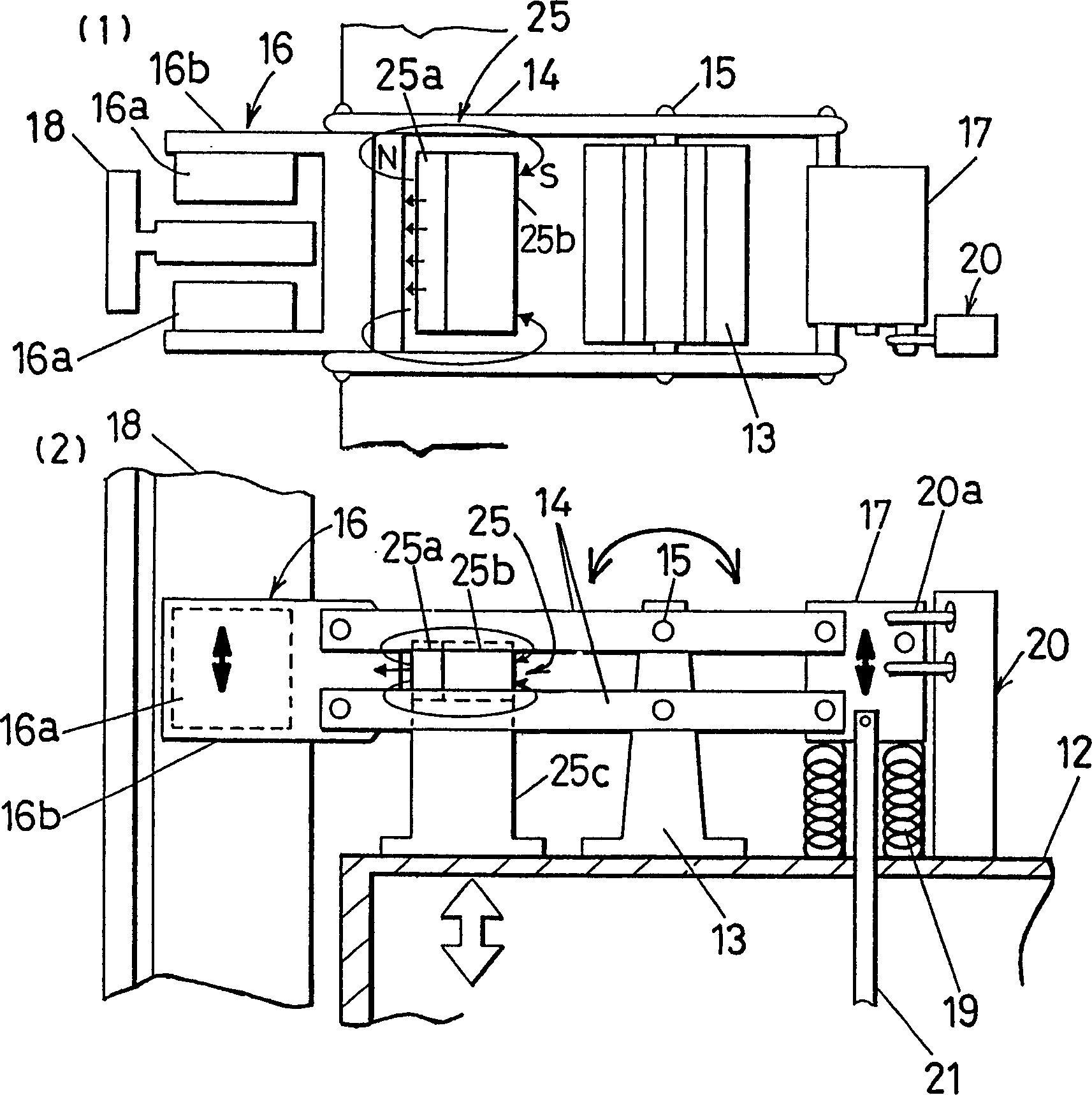

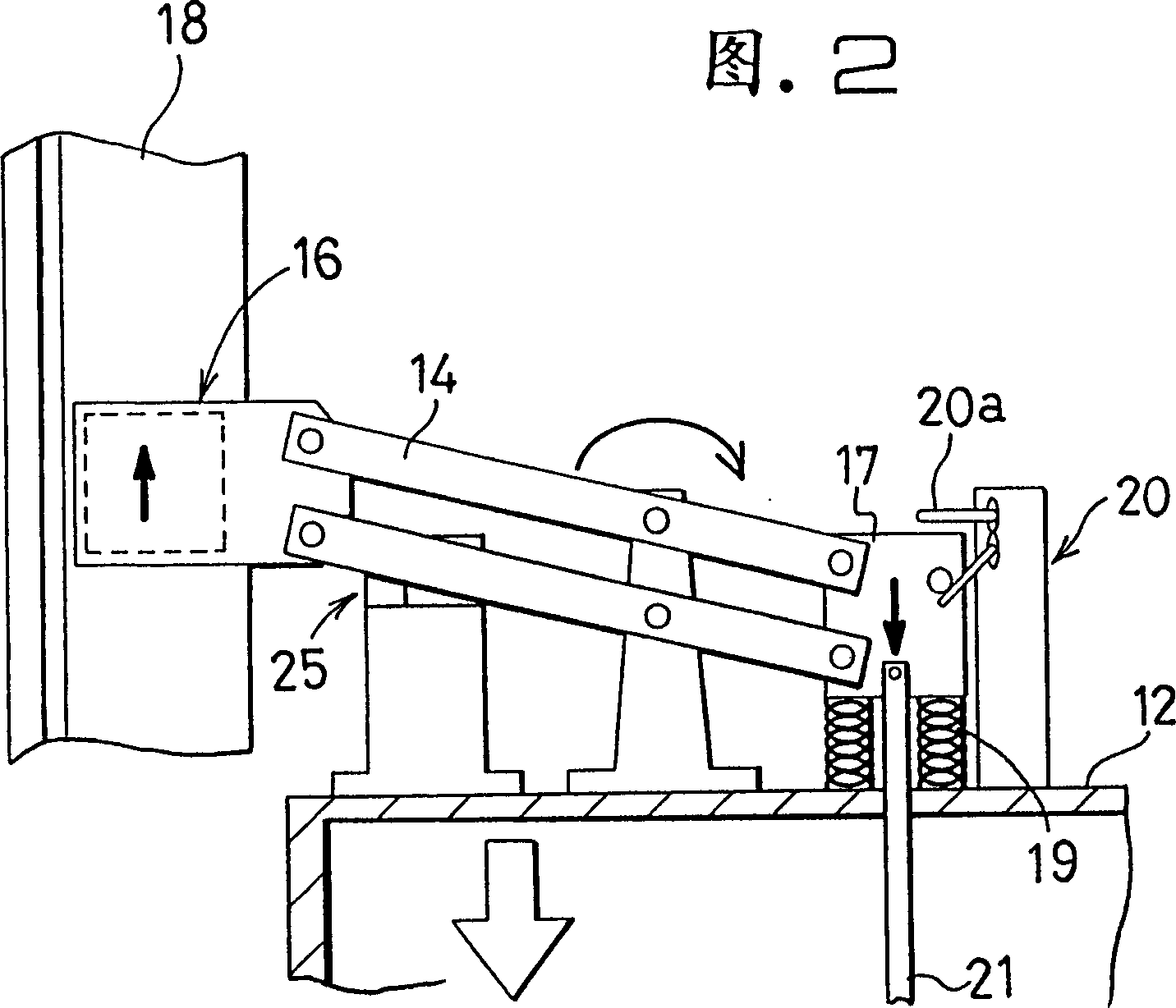

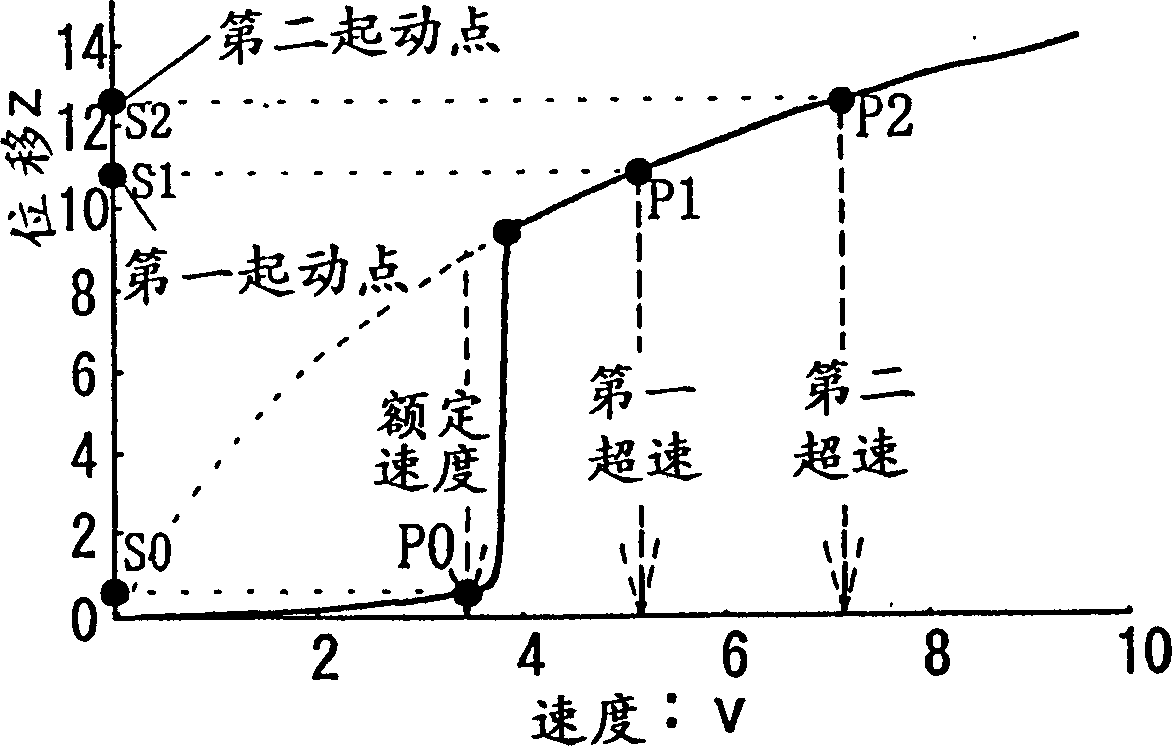

[0219] Referring to Fig. 1 (1) and 1 (2), label 12 refers to the car of an elevator, 13 refers to the base that is located on the car 12, 14 refers to the arm that is formed as a pair of parallel link forms, 15 refers to and is located on the base 13 The fulcrum that is used to support the arm 14 to rotate, 16 refers to the sensor that is rotatably installed on one end of the arm 14 and is used to detect the speed of the compartment 12, 16a refers to a pair of magnets that are arranged in a relative relationship, and 16b refers to fixing the pair of magnets. 17 refers to the counterweight used for balancing with the sensor 16 on the other end of the arm 14, while 18 refers to a conductor that is fixedly arranged along the side of the compartment 12 such as a guide rail, and the magnet from the sensor 16 is connected to the fork frame. The magnetic flux emitted by 16a passes through a plate-shaped portion extending from the center of the conductor 18, toward the carriage 12 and ...

Embodiment 2

[0229] The arm 14 in embodiment 1 is to take the form of parallel link, but in this embodiment 2, as shown in Fig. 6 (1) and 6 (2), arm 14 at this moment is made by connecting sensor 16 and A single link of the counterweight 17 is formed. Due to this structure, the structure of the arm 14 is simplified and can be formed with a reduced number of parts and a reduced cost.

Embodiment 3

[0231] In Embodiment 1, the pair of magnets 16a is arranged on two opposite sides of the conductor 18 so that the conductor 18 is held between the pair of magnets 16a. In Embodiment 3, the pair of magnets 16a is shown in Fig. As shown, it is only arranged on one side of the conductor 18, the structure of the magnetic circuit of the sensor 16 is simplified, and the number of components and the cost can be reduced at the same time. Furthermore, due to the reduced weight of the sensor 16, its dynamic response is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com