Driving method and driver for active luminous display panel

A technology of light-emitting display and driving method, which is applied in the direction of lighting devices, electroluminescent light sources, light sources, etc., and can solve the problems of poor linearity of gray scale control, decreased luminous efficiency, and reduced lighting time rate of EL elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

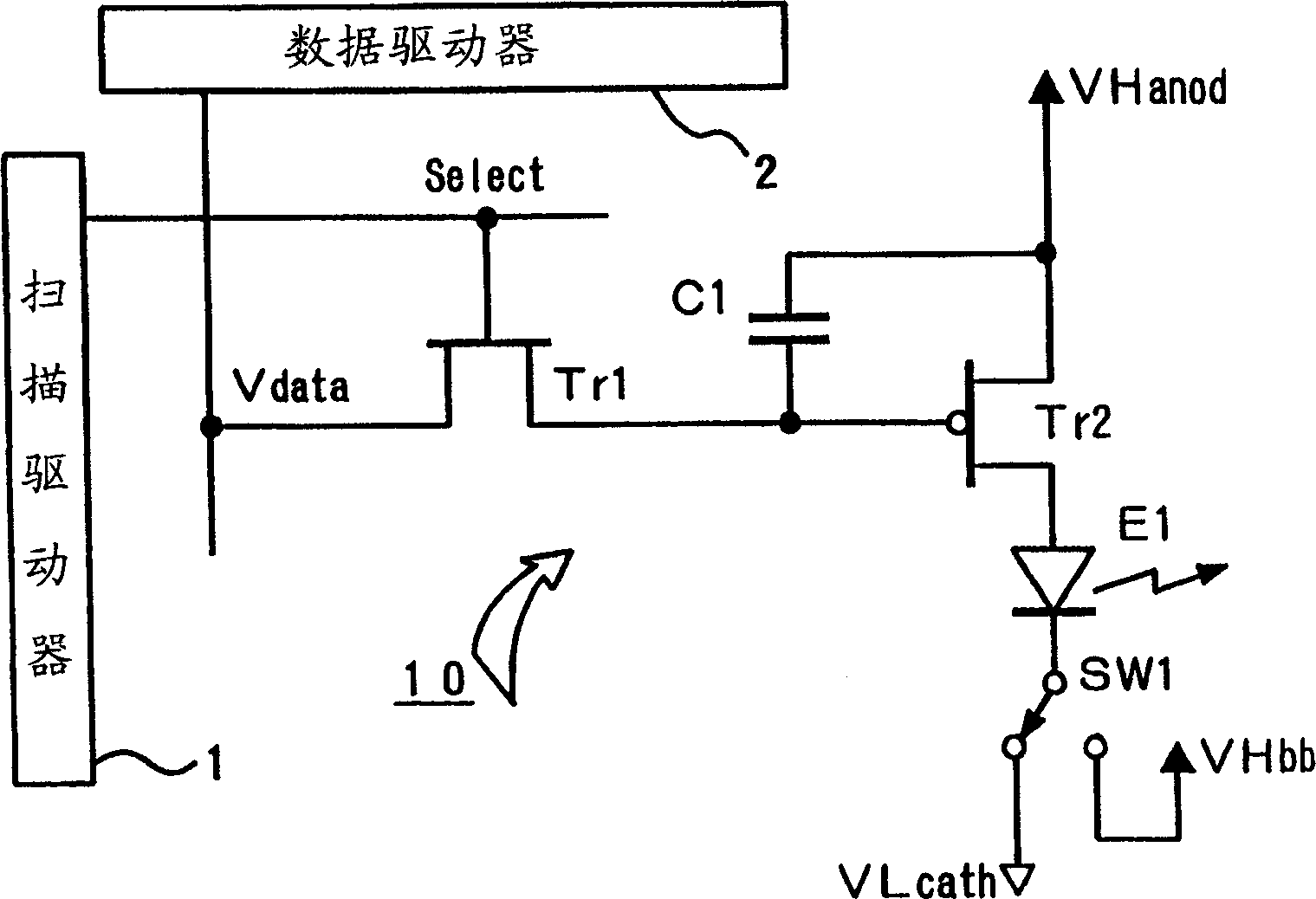

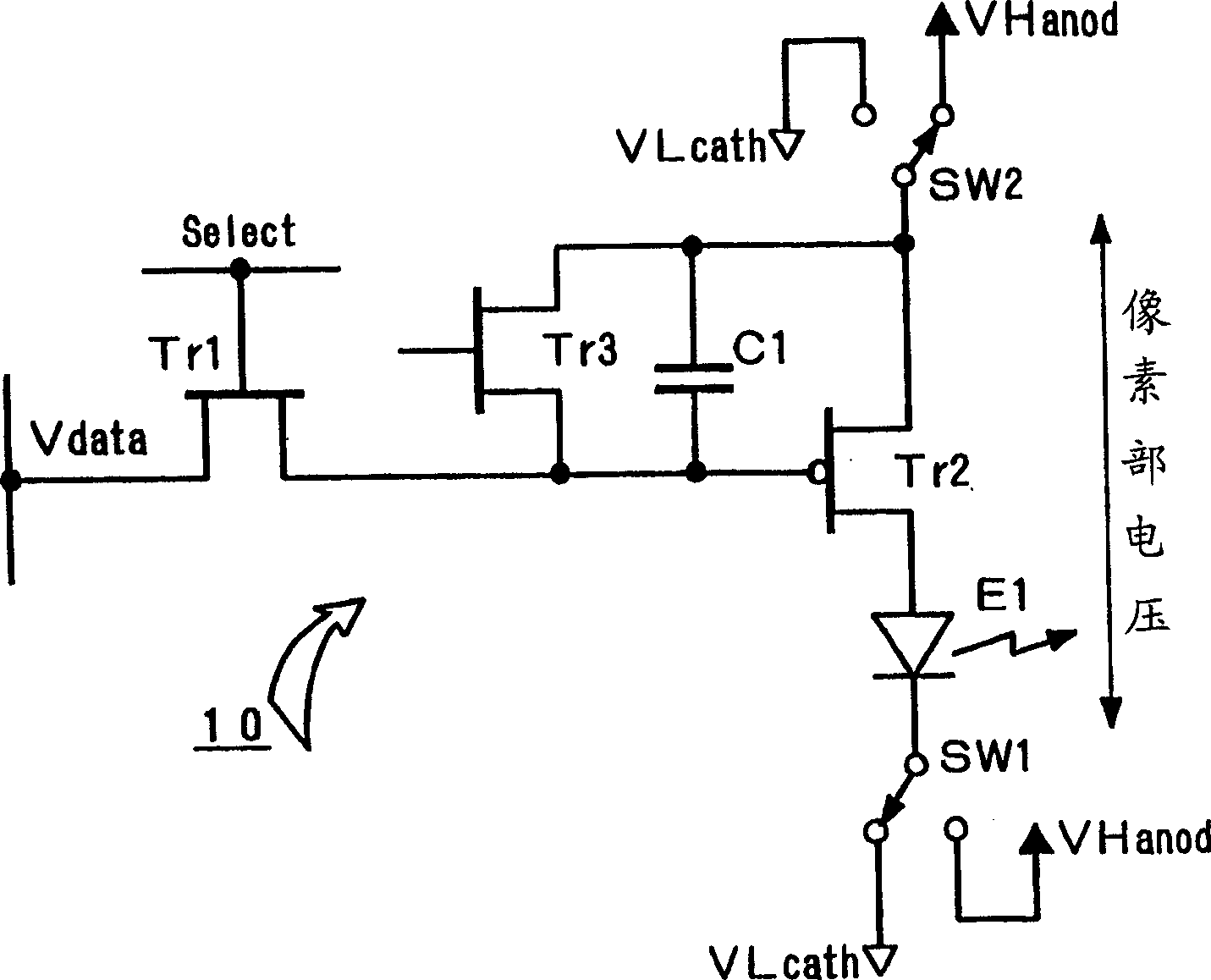

[0042] Hereinafter, the drive device for a light-emitting display panel of the present invention is divided into first to fifth aspects, and their respective features will now be described. First, the first aspect of the driving device of the present invention is characterized in that the parasitic capacitance accumulated in the above-mentioned light-emitting element is reduced by setting the anode and cathode of the light-emitting element at the same potential when the light-emitting element shifts to the lighting operation. The discharge work in which the charge is discharged.

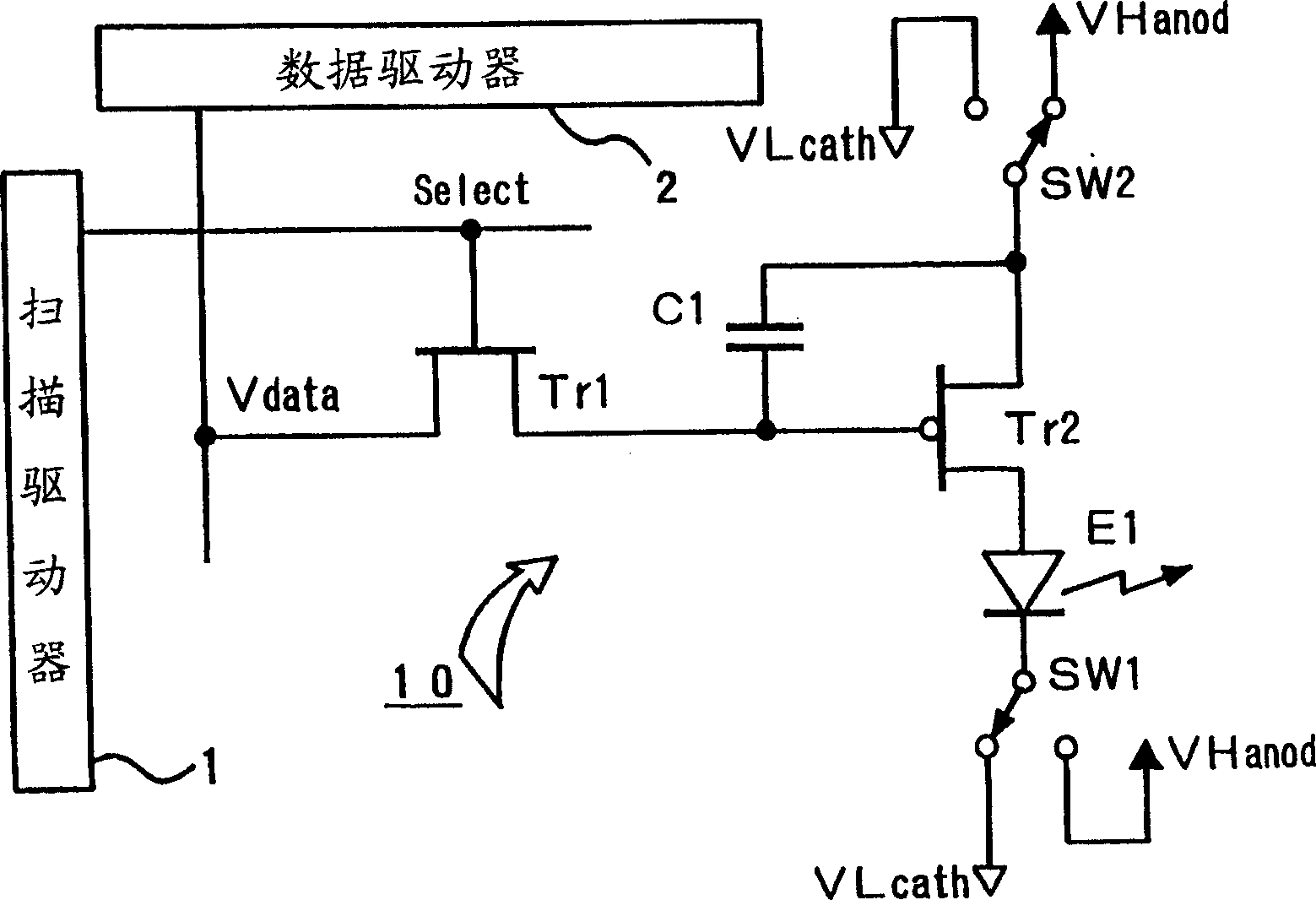

[0043] Then, in the first embodiment of the first aspect of the driving device of the present invention, as figure 2 As shown, the first and second switching switches SW1 and SW2 are provided, and by switching the switches SW1 and SW2, it is applied to an example configured to switch the connection relationship between the anode side power supply (VHanod) and the cathode side power supply (VLcath). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com