Screw compressor

A screw compressor and screw technology, applied in the direction of rotary piston machinery, mechanical equipment, engine components, etc., can solve the problems of liquid refrigerant, insufficient lubrication of cylindrical roller bearings, etc., to eliminate the need to use oil, The effect of simplifying the structure and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below with reference to the accompanying drawings.

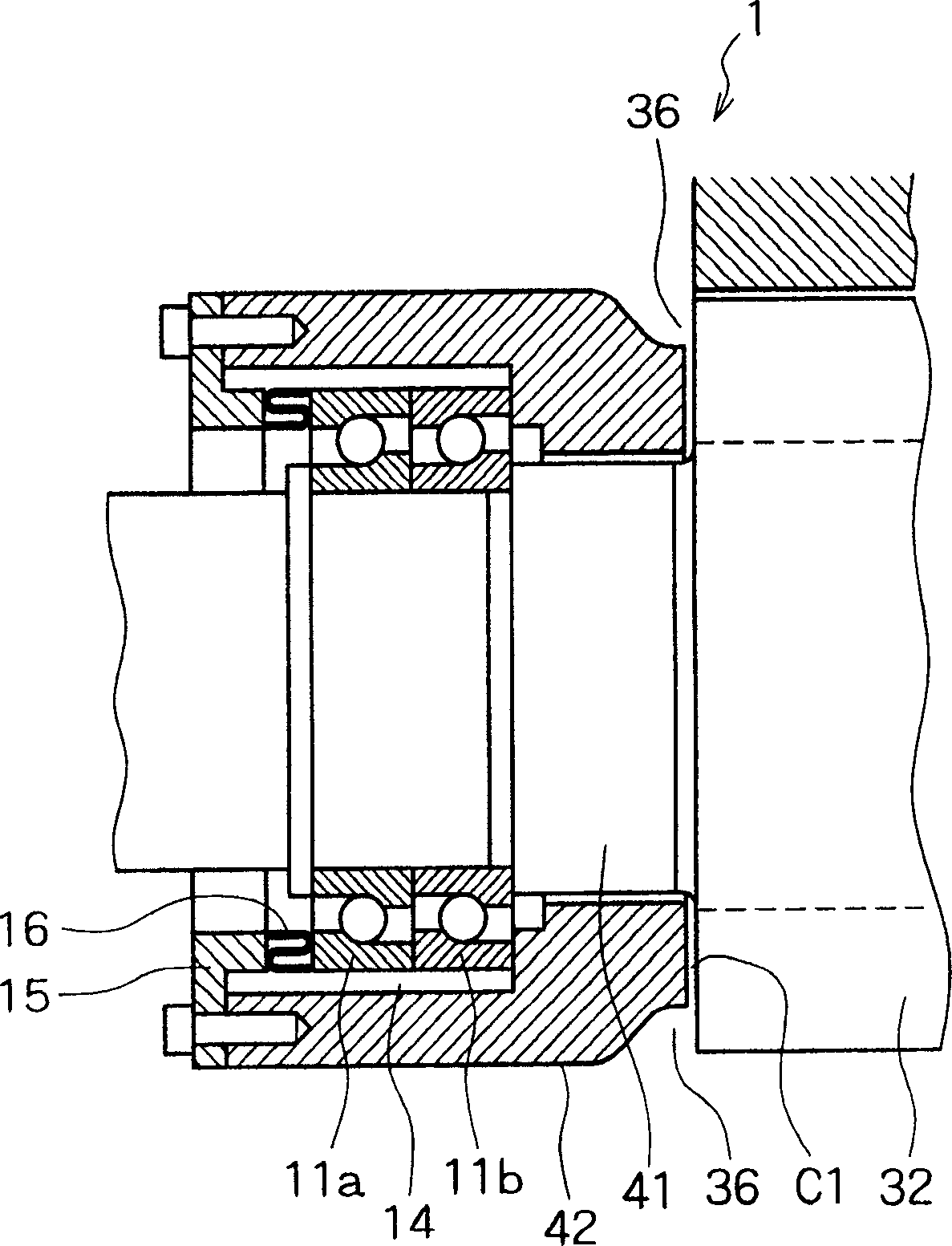

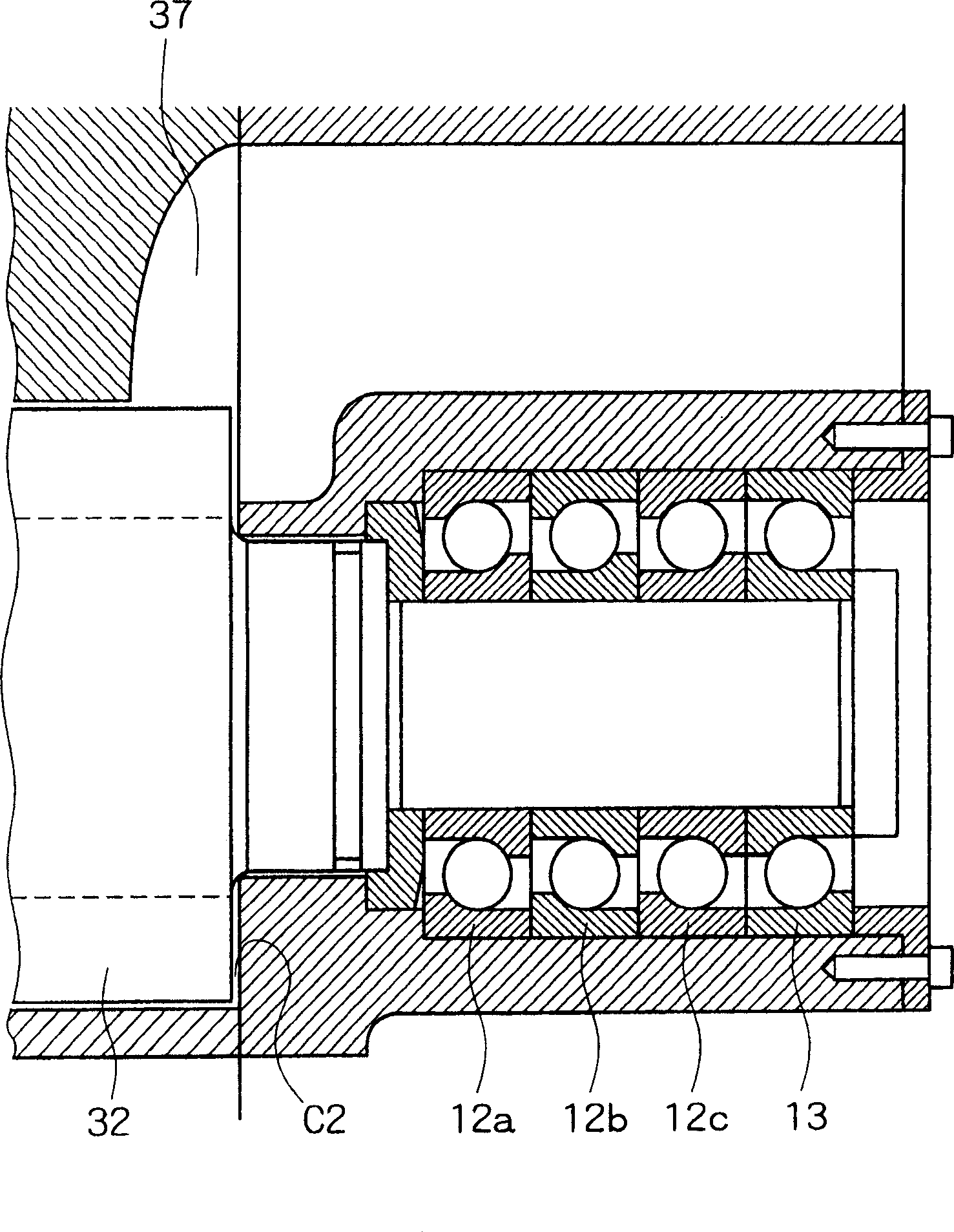

[0025] Figure 1-3 A screw compressor for a refrigeration device according to the invention is shown.

[0026] The screw compressor 1 has a pair of intermeshing male and female rotors 32 and a motor 33 in an integral housing 31 . A gas inlet 35 is formed at one end of the integral case 31 , and the gas inlet 35 is provided with a filter 34 . The discharge port 36 is formed at one end of the screw rotor 32 near the motor 33 , and the discharge port 37 is formed at the opposite end of the screw rotor 32 .

[0027] The suction side rotor shaft 41 of one of the paired male and female rotors 32 is as figure 1 As shown, the rotor shaft 41 is connected to the input shaft 49 of the motor 33 so as to rotate integrally, and the motor 33 rotates the screw rotor 32 .

[0028] When the screw compressor 1 is applied to a refrigeration device, the gaseous refrigerant enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com