Weft throwing nozzle of fluid spraying type weaving machine

A technology of fluid jetting and nozzles, applied in the directions of looms, jetting devices, jetting devices, etc., can solve the problems of increasing fabric defects due to diffusion, and the connection of gap size without any discussion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

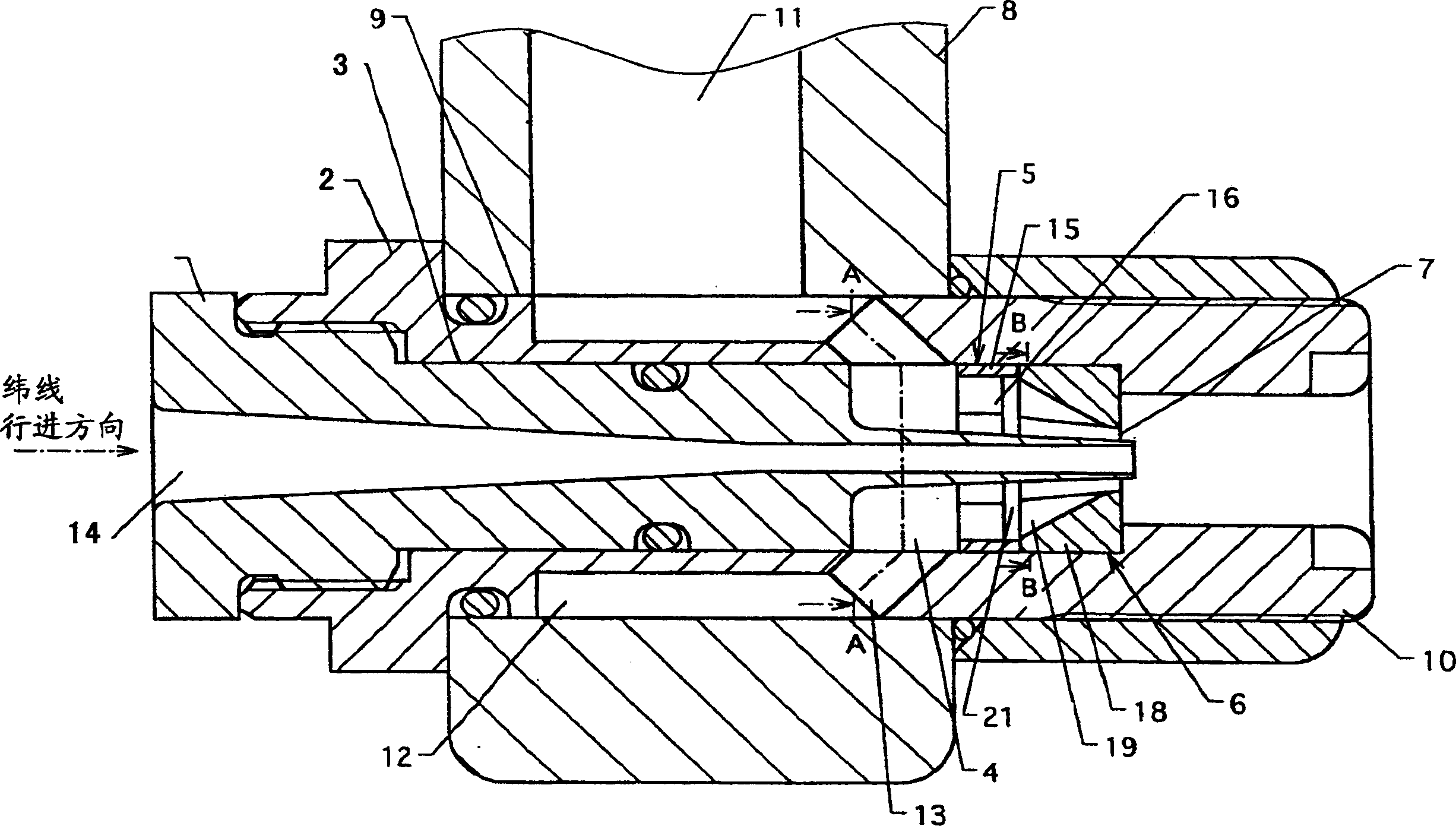

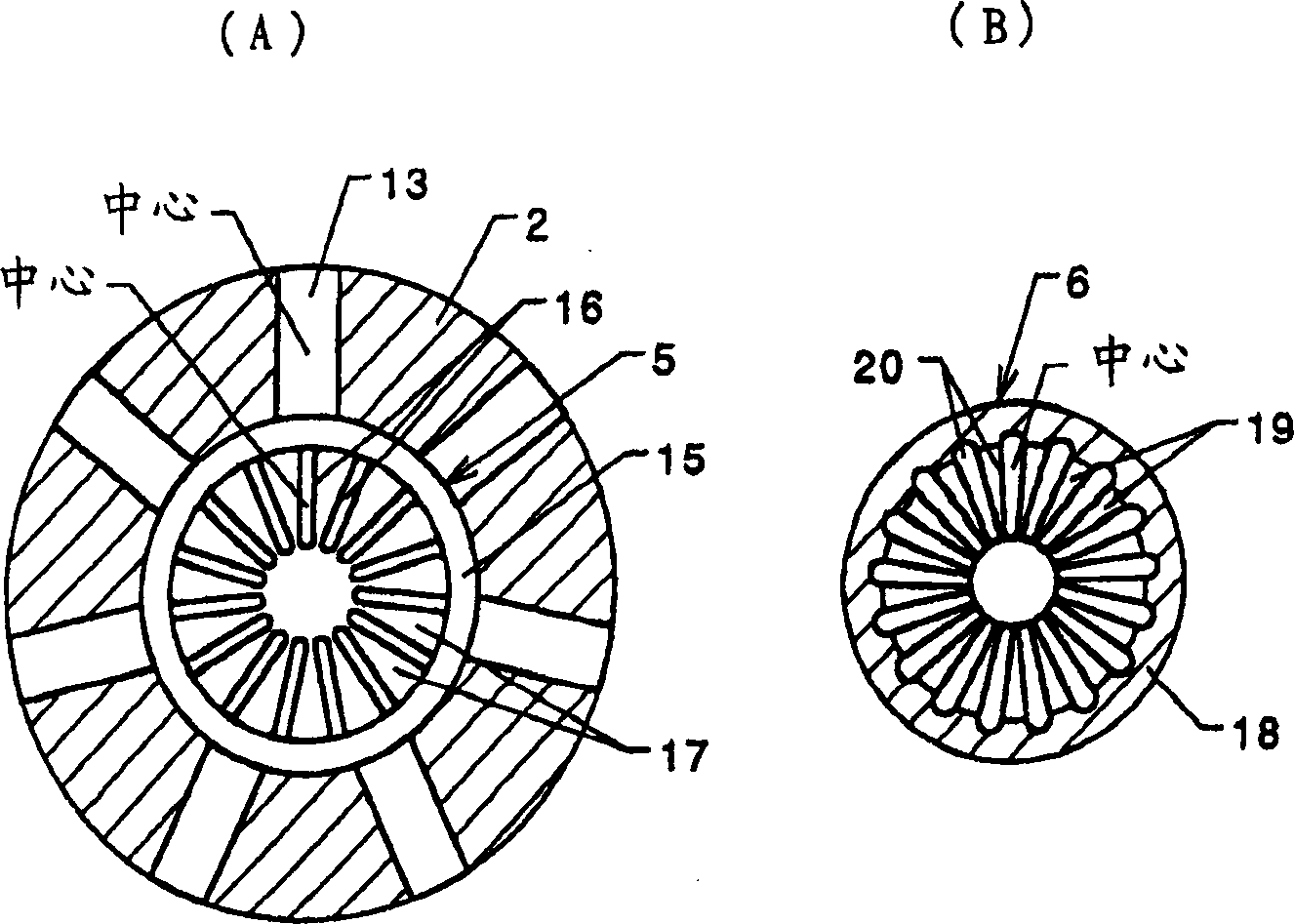

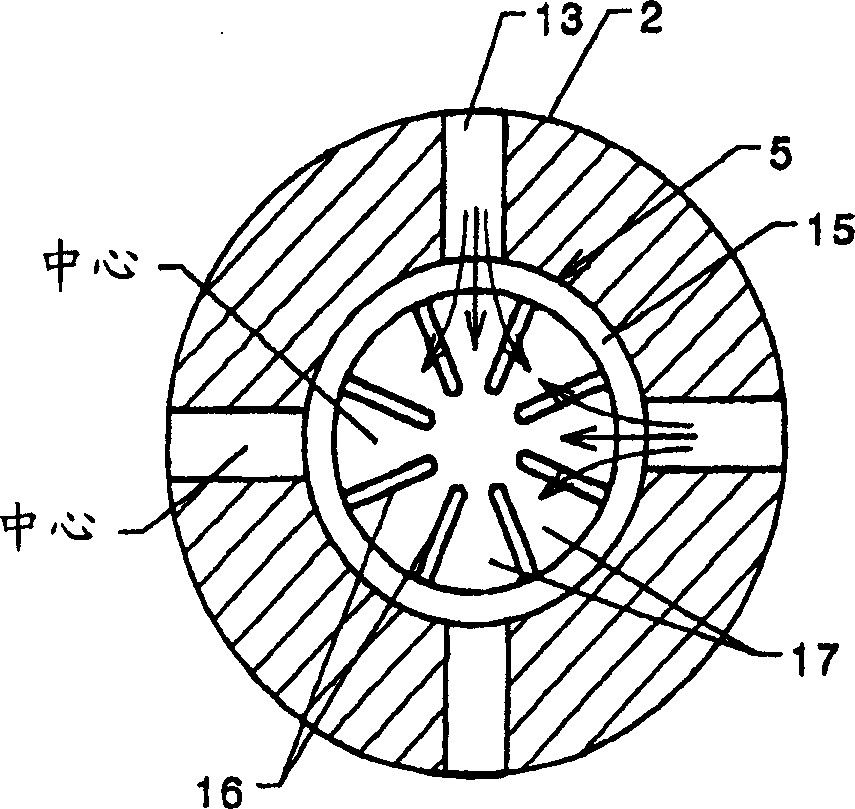

[0043] Such as figure 1 As shown, the weft throwing nozzle of the fluid jet loom inserts the knitting needle 1 into the hollow part 3 of the nozzle body 2, and an annular flow path is formed between the front part of the knitting needle 1 and the nozzle body 2. The rear part of the flow path is used as the annular chamber 4, and the first and second rectifying members 5, 8 are sequentially arranged in the front part of the flow path and along the weft traveling direction. Between the first and second rectifying members 5, 6 and the knitting needles A flow path is formed therebetween, and a fluid injection hole 7 is formed between the knitting needle 1 and the tip of the second rectifying member 6. The nozzle body 2 is inserted into the insertion hole 9 at the front of the nozzle holder 6 formed in a cylindrical shape, and the nozzle cover 10 is screwed onto the outer side of the front of the nozzle body 2 to fix the nozzle body 2 to the nozzle holder. 8, an annular groove 12 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com