Pepper oil, preparing method thereof and producing apparatus therefor

A production equipment and technology of pepper oil, applied in the directions of fat oil/fat production, fat production, food science, etc., can solve the problems of loss of fragrant hemp flavor, coking of prickly ash fruit, unfavorable human health, etc., and achieve convenient use, fragrant hemp flavor and strong flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

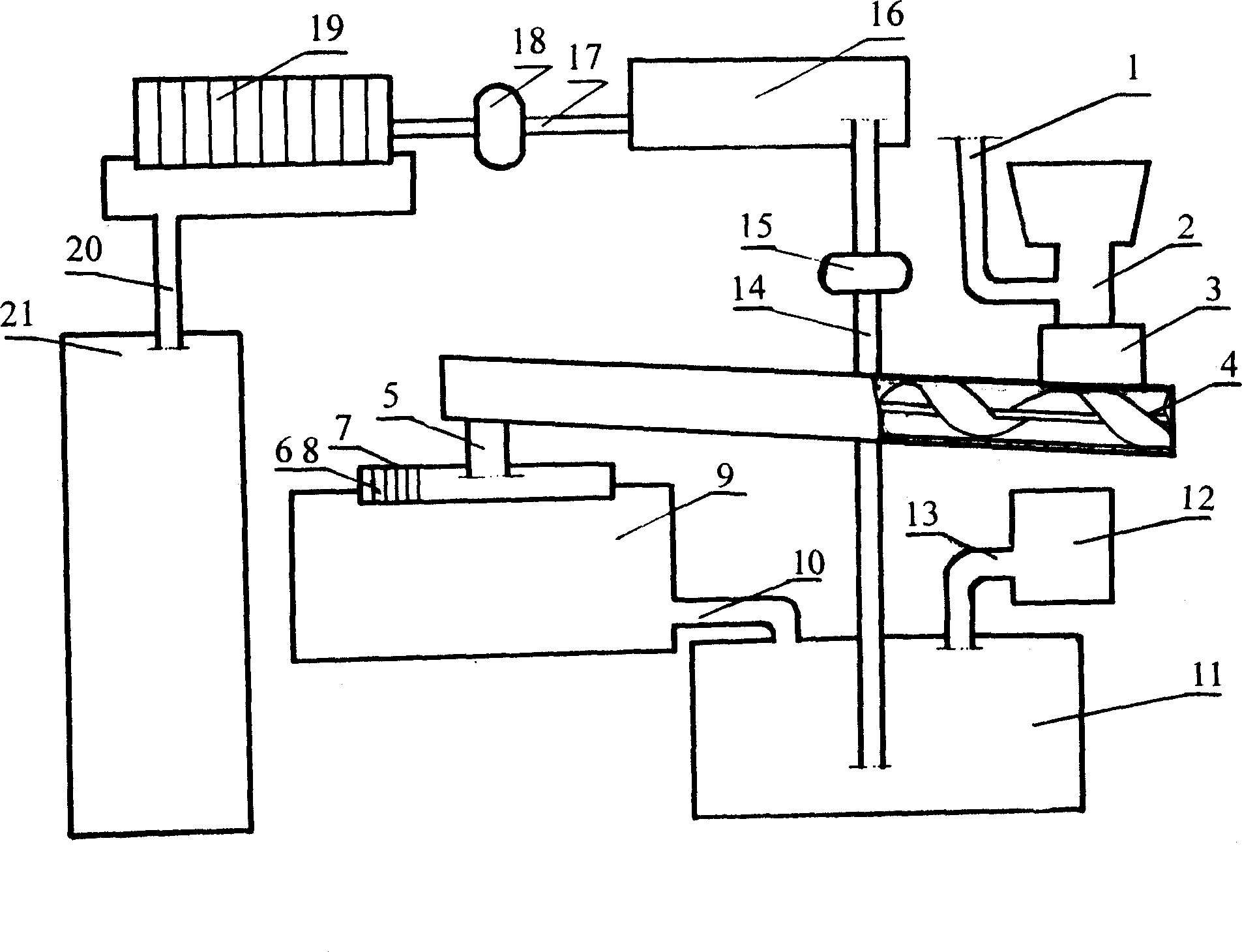

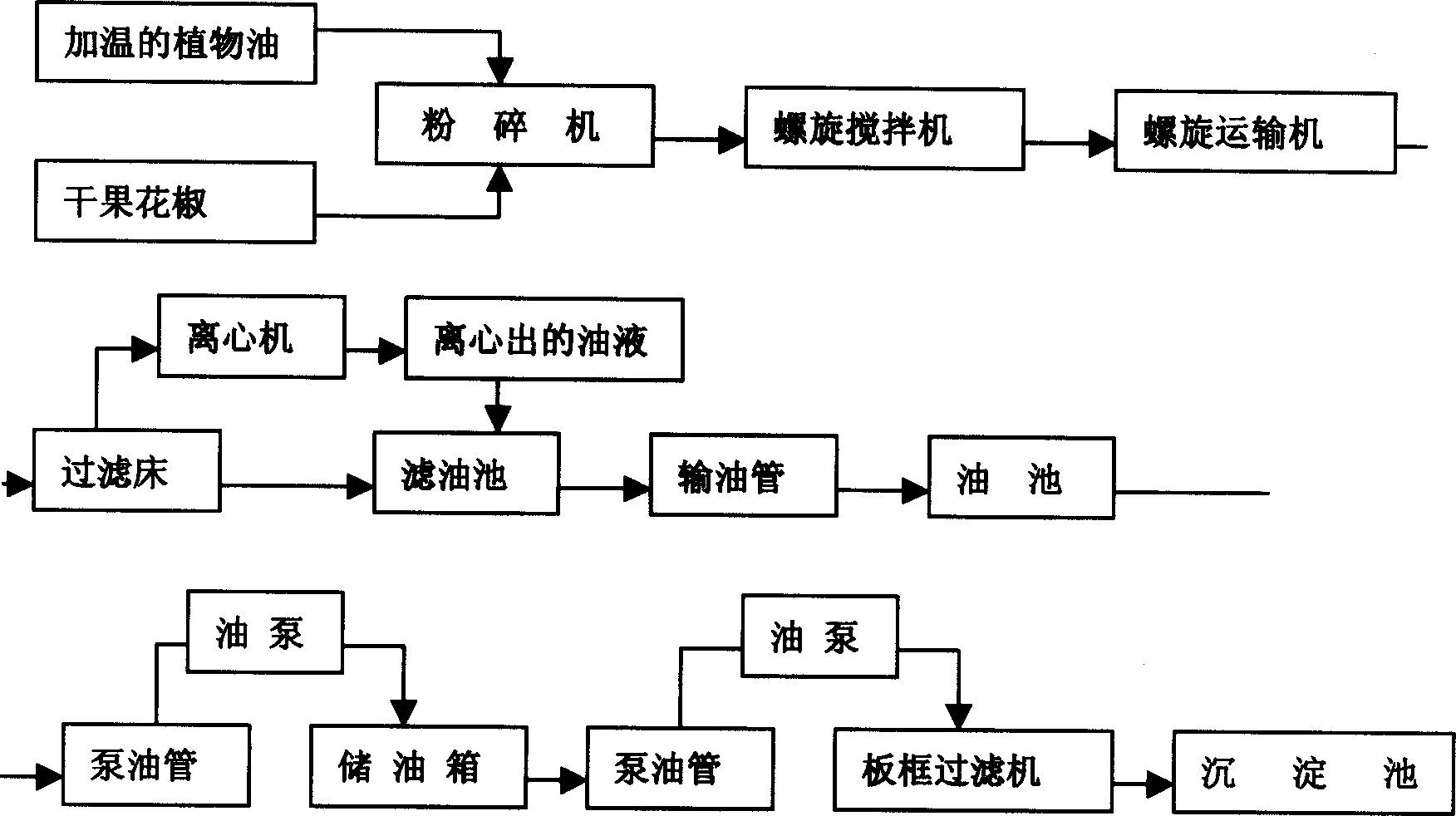

[0020] combined with figure 1 , 2 Explain the method and production equipment of using dried Zanthoxylum bungeanum to make Zanthoxylum bungeanum oil: according to the ratio of rapeseed oil and dried Zanthoxylum bungeanum weight 10:1, weigh 1000kg of rapeseed oil and 100kg of dried Zanthoxylum bungeanum; heat the rapeseed oil to 120°C-125 ℃, enter the pulverizer 2 through the hot oil pipe 1, and at the same time, put the dried peppercorns into the pulverizer 2 with a rotation speed of 3500 rpm through the pulverizer inlet, and complete the pulverization synchronously with stirring; the pulverized mixture flows into The rotating speed is 35 rev / min mixers 3, stirring for 25 minutes; the agitator flows into the screw conveyor 4 at the lower end of the horizontal position, and is soaked in the hot oil of the screw conveyor 4 at a speed of 25 rpm / min for 9-12 minutes. Minutes later, and pushed into the discharge port 5 at the higher end of the horizontal position; then flow into t...

Embodiment 2

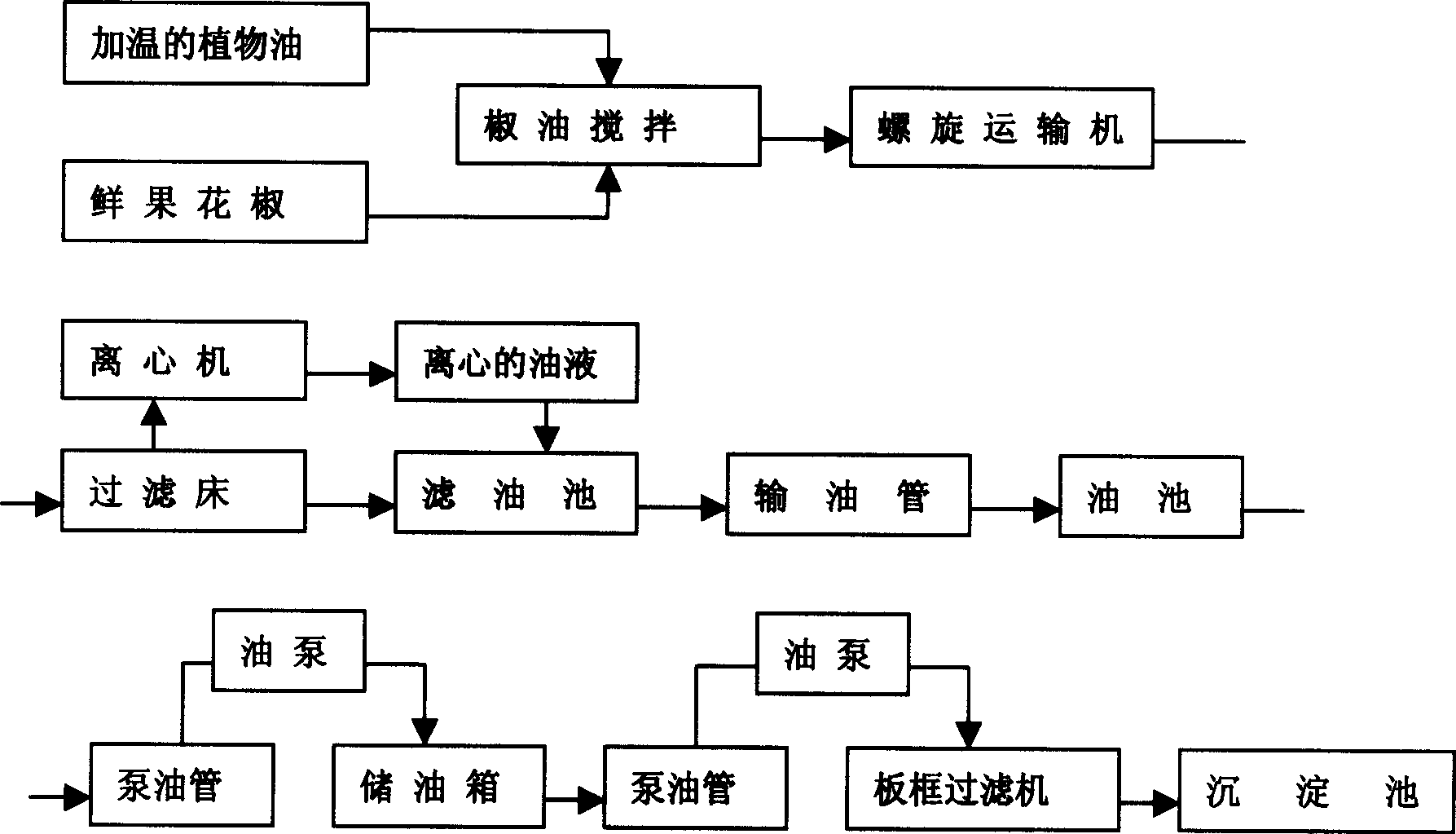

[0022] combined with figure 1 , 3 , illustrate the method and production equipment that utilize fresh Zanthoxylum bungeanum to make Zanthoxylum bungeanum oil: by the ratio of 2:1 of rapeseed oil and fresh Zanthoxylum bungeanum weight ratio, take by weighing 2000kg of fresh Zanthoxylum bungeanum 1000kg; Rapeseed oil is heated to 190 ℃- At 195°C, the oil is sprayed on the fresh Zanthoxylum bungeanum through the hot oil pipe 1, and the spraying and stirring are carried out simultaneously, and then enters the screw conveyor 4, soaked, and the following production process steps are the same as in Example 1, and 2000kg of Zanthoxylum bungeanum oil can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com