Wedge type freewheeling clutch apparatus

An overrunning clutch and wedge-type technology, which is applied to clutches, one-way clutches, mechanical equipment, etc., can solve the problems of only design and manufacture, high precision and poor consistency of wedge manufacturing, and achieve uniform wear and compressive stress. Small, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

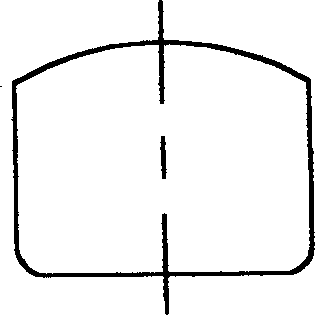

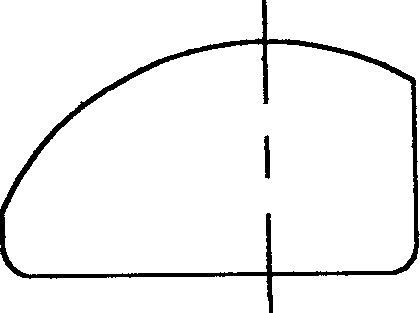

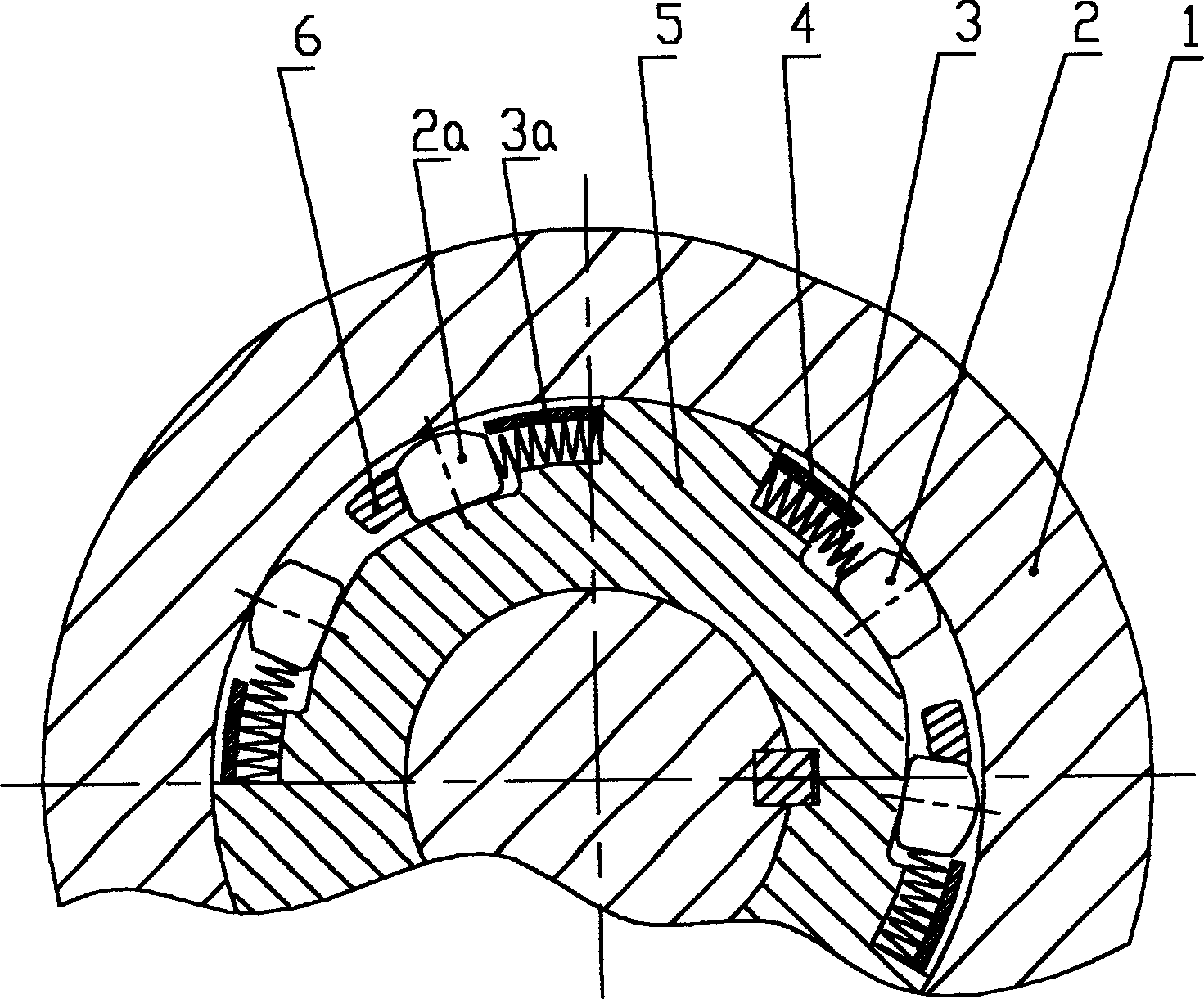

[0019] image 3 The wedge-type controllable overrunning clutch with claws shown is mainly composed of an outer ring 1, wedges 2 and 2a, springs 3 and 3a, a cage 4, a star wheel 5, and a claw 6. The notch has two working surfaces in opposite directions and forms two wedge seams with the outer ring 1; wedges 2 and 2a with the characteristics of the present invention are respectively housed in each wedge seam, and the wedges that push the wedges into contact with the inner cylindrical surface of the outer ring Springs 3 and 3a; in the middle of the two wedges, there is a claw 6 that is limited by an elastic structure and usually presses a wedge that does not contact the outer ring. The elastic structure that limits the claw 6 is connected to the star wheel 5 .

[0020] When the star wheel 5 rotates counterclockwise as the active part, the claw 6 presses the wedge 2a not to contact the outer ring 1 and rotates synchronously with the star wheel 5 under the action of the elastic mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com