Disconnecting switch and contact mechanism thereof

A technology of isolating switches and contacts, applied in the direction of electric switches, electrical components, circuits, etc., can solve problems such as unsuitable for remote operation, unreasonable layout of arc extinguishing chamber, and failure to meet the requirements of quick breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it should not be understood that the protection scope of the present invention is limited to the following embodiments.

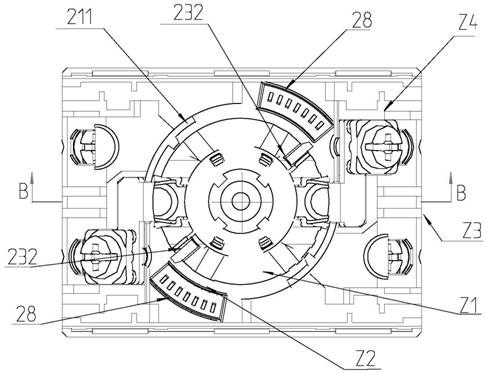

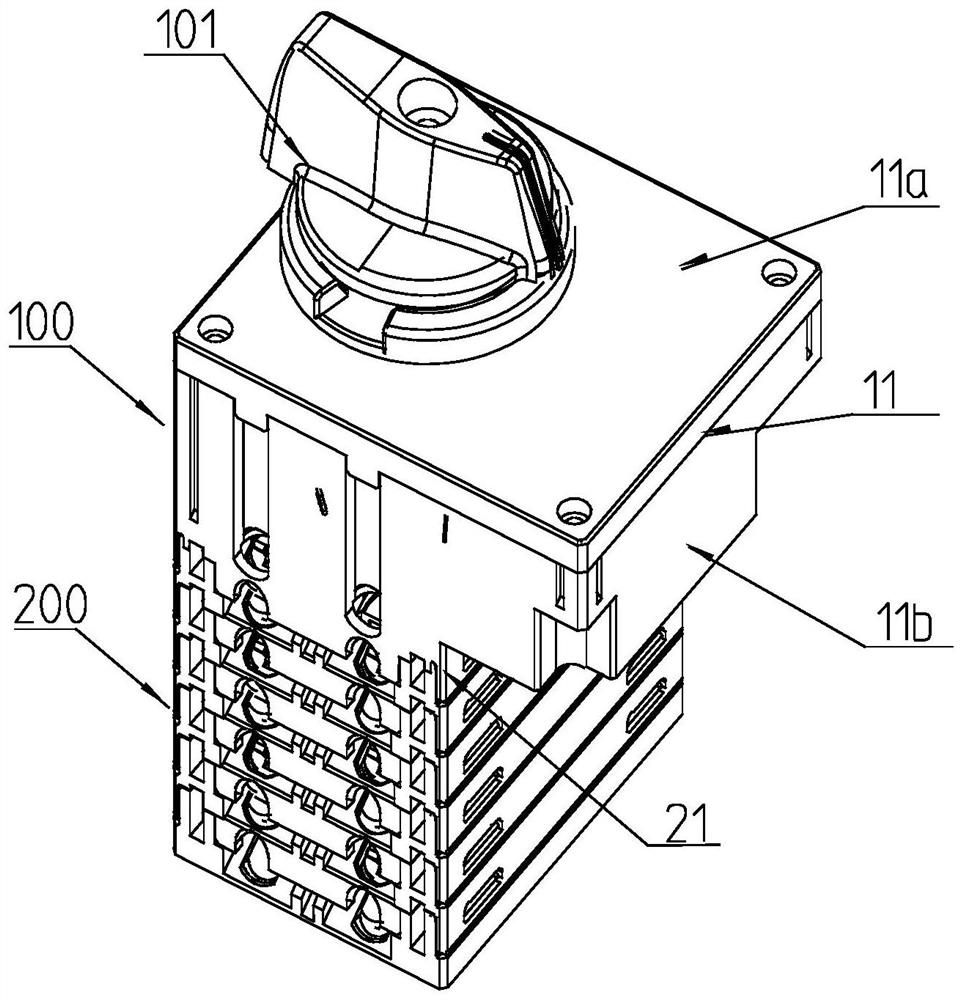

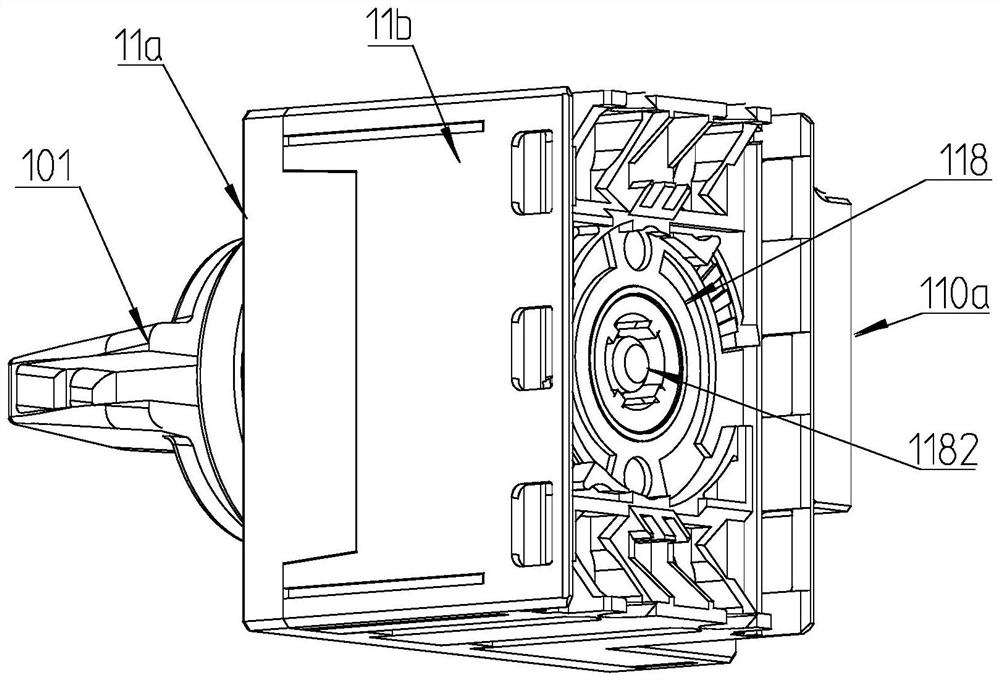

[0051] 1 product machine

[0052] see figure 1 , and also see figure 2 and Figure 13 , showing the overall structure of the isolating switch product of the present invention. like figure 1 As shown, the isolating switch includes a mechanism pole 100 and a contact pole 200 , wherein the mechanism stage 100 is provided with an opening and closing device 100 a for driving the contact mechanism 200 a of the contact pole 200 . Among them, the opening and closing operation can be carried out manually or automatically: when it is manual, it is realized by rotating the main shaft through the knob 101; when it is automatic, it is realized by directly driving the opening and closing parts, and the opening action can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com