Double-synchronous direct-acting belt drive roller shutter type flapping-wing unmanned aerial vehicle

A belt-driven, double-synchronous technology, applied in the field of dual-synchronous direct-drive belt-driven rolling-shutter flapping-wing UAVs, can solve the problem of inability to achieve vertical take-off and landing and hovering in the air, restricting the popularization and application of flapping-wing aircraft, and flapping-wing drones. The overall efficiency of the aircraft is low and other problems, to achieve the effect of simple structure, low production cost, and flapping wings synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

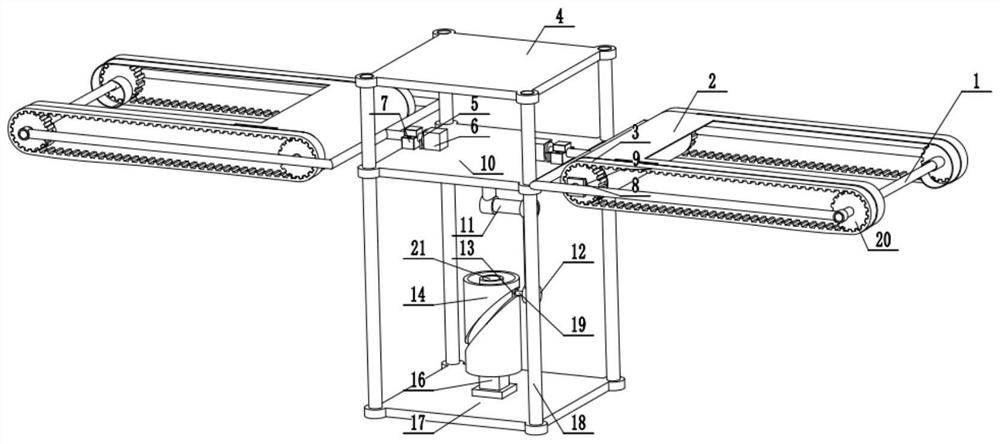

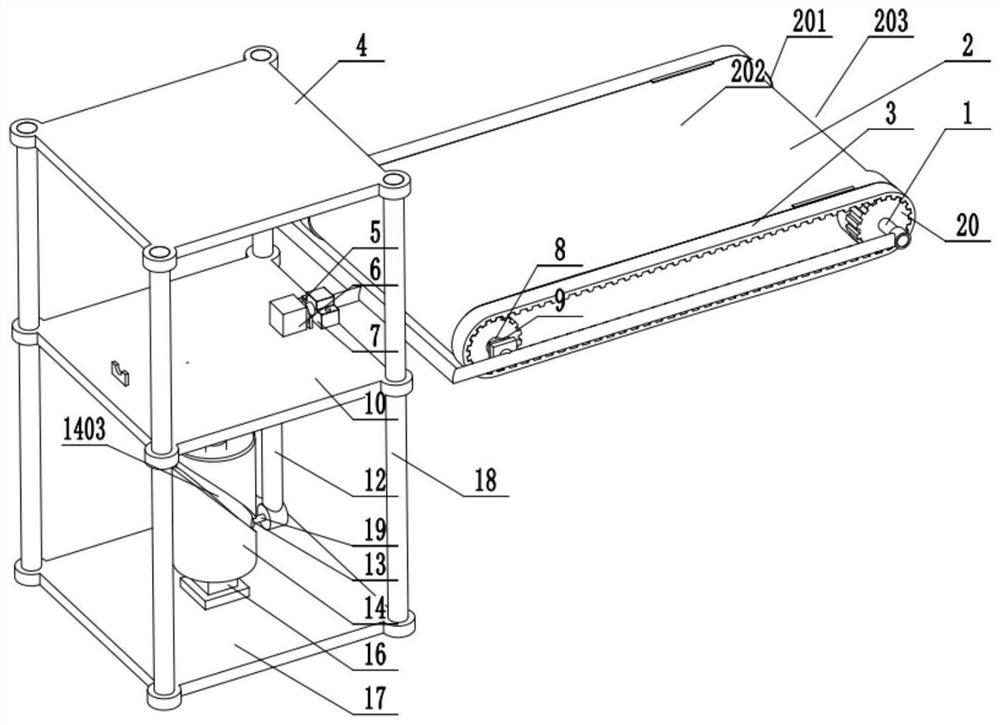

[0034] Example 1: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a high-voltage wire inspection UAV that adopts a double-synchronous direct-motion belt-driven rolling shutter flapping-wing UAV. Including flapping wings, fuselage top plate 4, first reducer 5, stepper motor 6, connector 7, second reducer 8, drive motor 9, transmission mechanism, third reducer 15, motor 16, fuselage bottom plate 17 and slideway 18, the fuselage top plate 4 is symmetrically installed and fixed with four vertical slideways 18, and the two connectors 7 are fixedly connected to the push rod 10 respectively, and the two flapping wings are respectively connected to the two connectors. 7 and can be relatively rotated, the flapping wing includes a flapping wing frame 1, and a roller blind 2 installed on the flapping wing frame 1, and the flapping wing frame 1 is also provided with a driving motor 9 and a second re...

Embodiment 2

[0035] Example 2: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a high-level fire-fighting drone that adopts dual-synchronous direct-motion belt-driven rolling shutter flapping-wing drones. Including flapping wings, fuselage top plate 4, first reducer 5, stepper motor 6, connector 7, second reducer 8, drive motor 9, transmission mechanism, third reducer 15, motor 16, fuselage bottom plate 17 and slideway 18, the fuselage top plate 4 is symmetrically installed and fixed with four vertical slideways 18, and the two connectors 7 are fixedly connected to the push rod 10 respectively, and the two flapping wings are respectively connected to the two connectors. 7 and can be relatively rotated, the flapping wing includes a flapping wing frame 1, and a roller blind 2 installed on the flapping wing frame 1, and the flapping wing frame 1 is also provided with a driving motor 9 and a second reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com