Compressor

A technology of compressors and two-stage compressors, applied in compressors, irreversible cycle compressors, refrigerators, etc., can solve problems such as performance degradation, large pressure difference, and pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

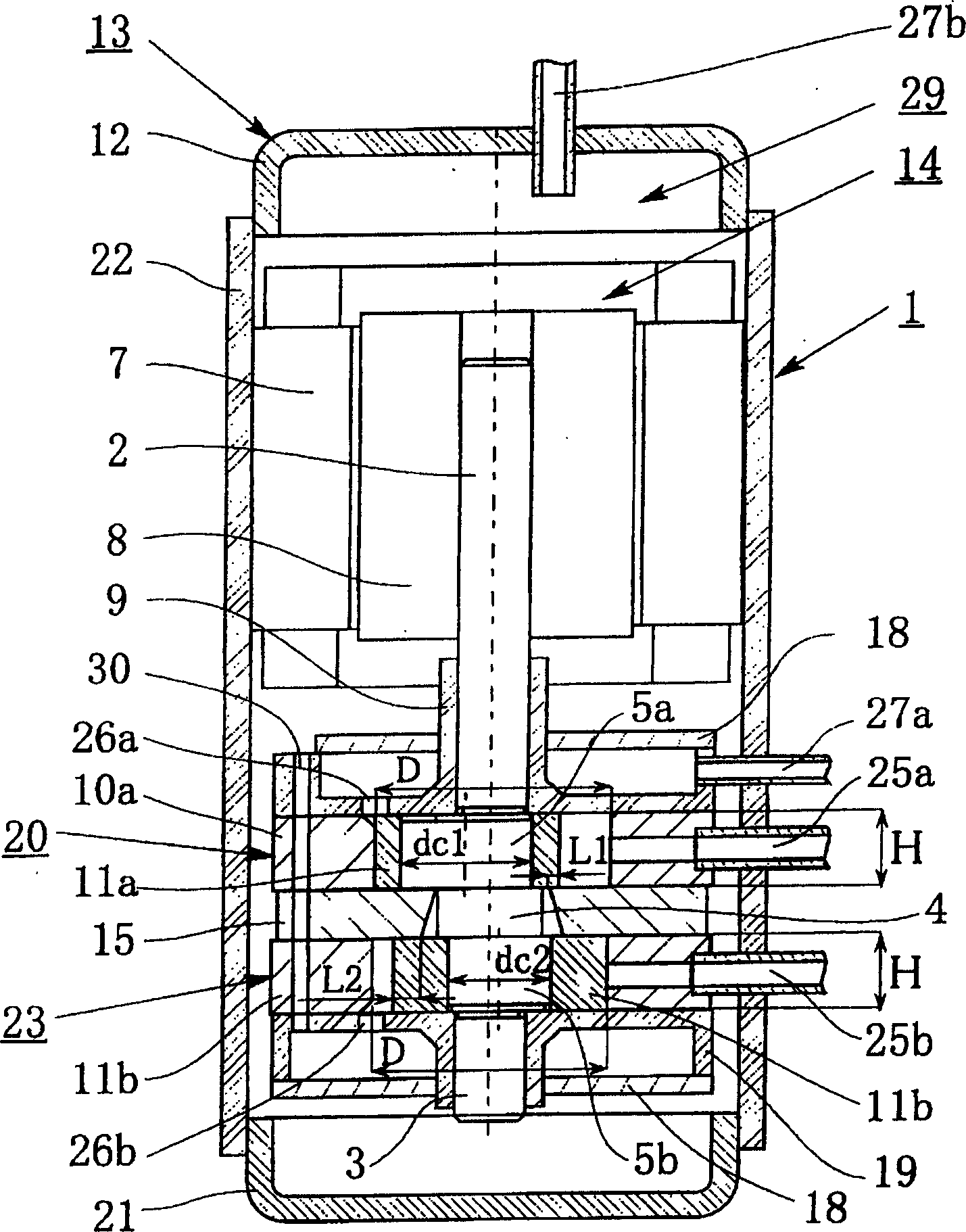

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Among them, for Figure 14 The symbols used for the same constituent elements in , for easy understanding of the embodiments of the present invention, are figure 1 The same notation is also used in .

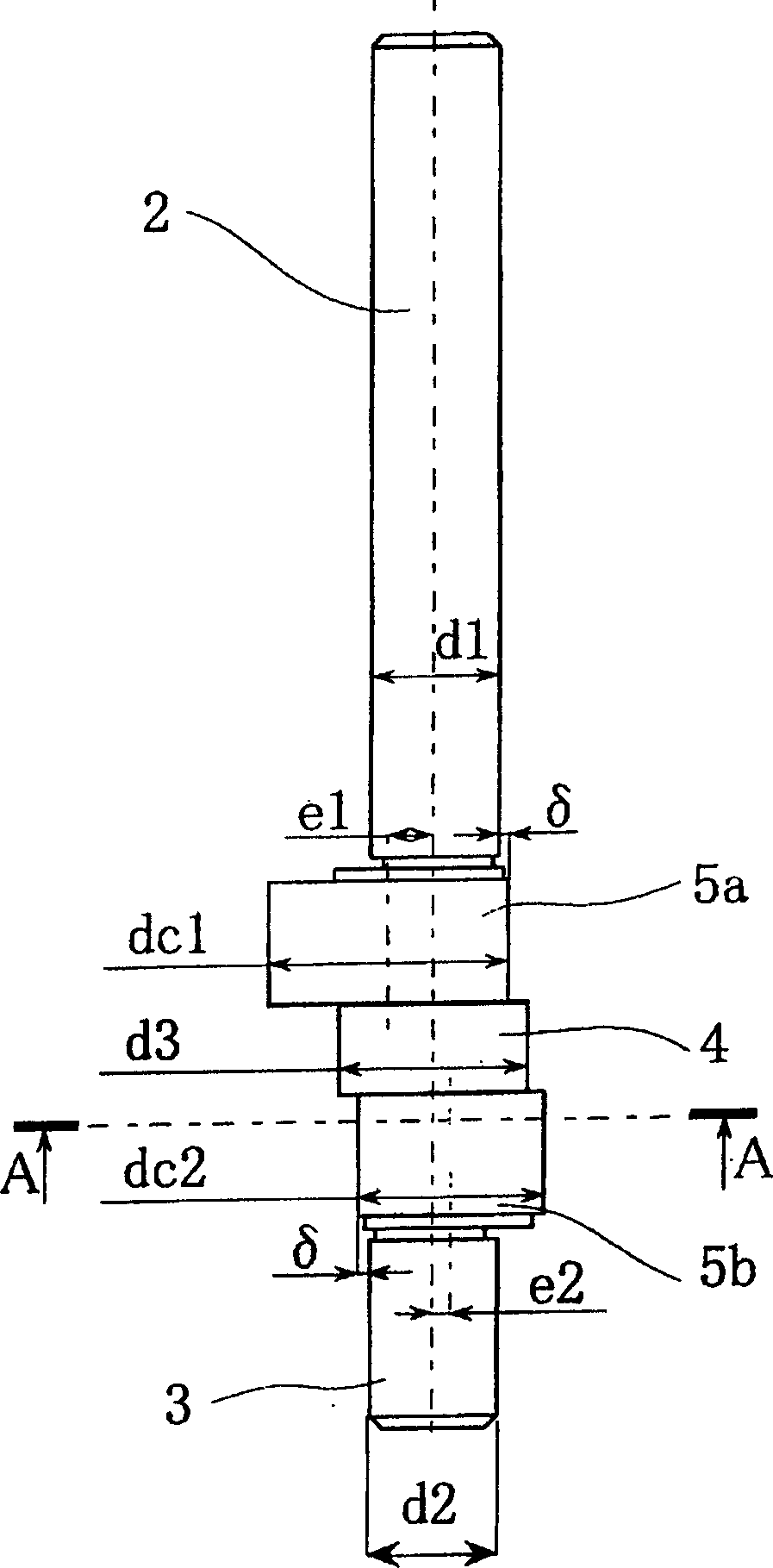

[0043] exist figure 1 Here, the outer diameter dc2 of the eccentric portion 5b of the high pressure compression element 23 is set smaller than the outer diameter dc1 of the eccentric portion 5a of the low pressure compression element 20 . However, the eccentricity e1, e2, cylinder inner diameter D, height H, and roller outer diameter dr, that is, the discharge amount Vcc are the same as the conventional one.

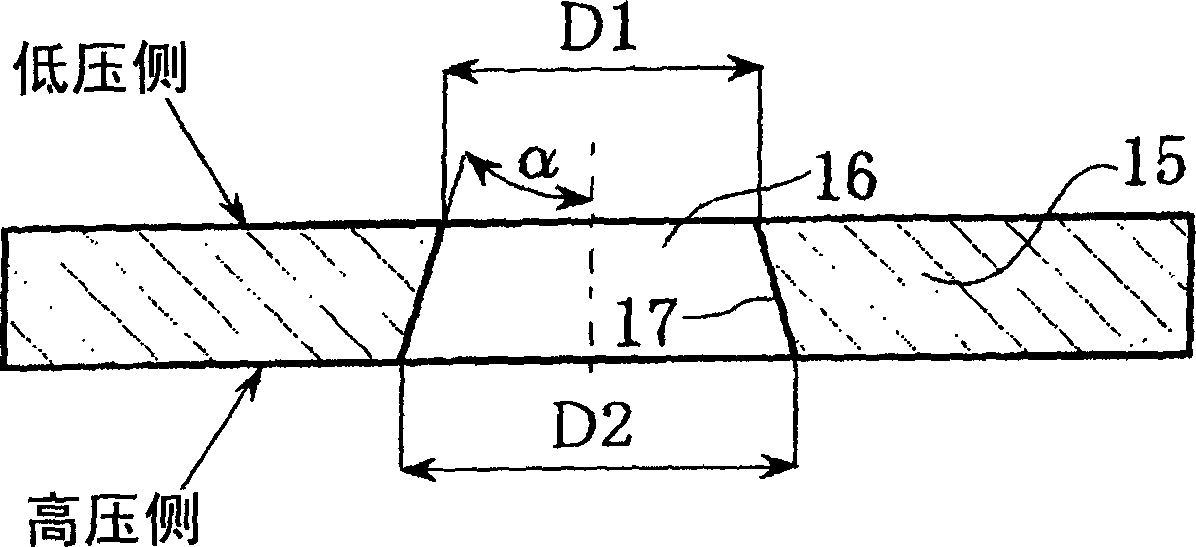

[0044] figure 2denotes the cross-sectional shape of the intermediate partition 15 . The intermediate partition plate 15 has the front end shaft 3 , the eccentric portion 5 b , and a through hole 16 for penetrating the intermediate shaft 4 . The diameter D1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com