Reflection type optical valve projection system

A reflective and light valve technology, applied in optics, optical components, instruments, etc., can solve the problems of reducing the brightness output of the optical system, low contrast, polar beam conversion loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

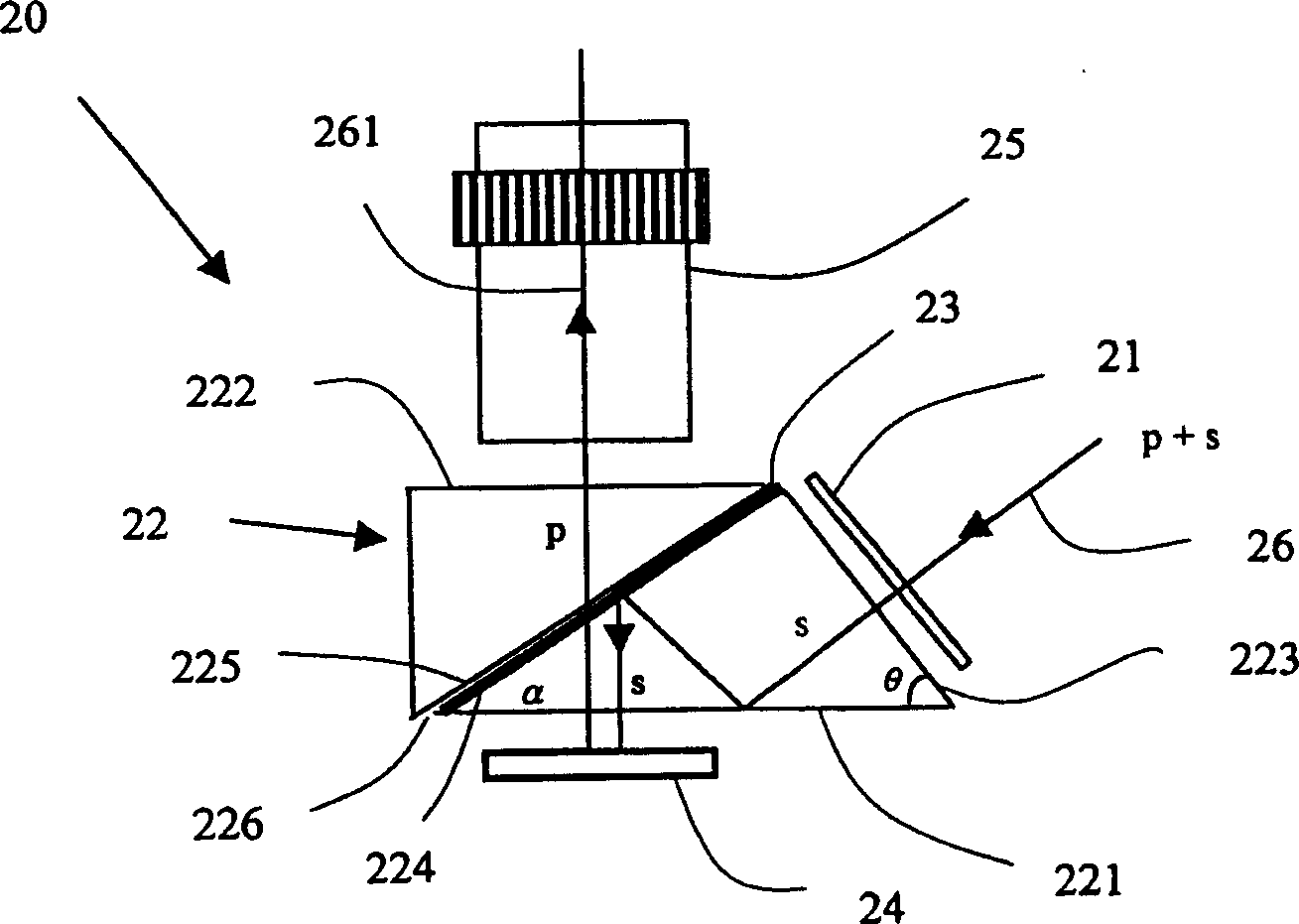

[0016] see figure 2 , is the imaging system 20 of the first embodiment of the present invention, including a polarizer 21 , a prism module 22 with a wire-grid polarizer 23 (Wire-Grid Polarizer), reflective light valve 24 and lens group 25 . Mainly through the polarizer 21 and the metal wire grid polarizer 23, the illumination beam 26 is polarized into a required polarity beam, incident to the reflective light valve 24, and then reflected to the lens group 25 to form an image.

[0017] Wherein, the prism module 22 of the imaging system 20 is a columnar prism with two substantially parallel outer surfaces 221 and 222, one side surface 223 is not parallel to the outer surfaces 221 and 222, and the inside of the prism module 22 has two outer surfaces 221, 222, The tangent planes 224 and 225 of the two opposite corners of 222 are substantially parallel to each other and separated by a small gap 226, wherein on the tangent plane 224 near the outer surface 221, a metal wire grid lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com