Yoke iron device for starting electric machine

A technology for starting motors and yokes, applied in electromechanical devices, motor starting for engines, engine components, etc., can solve problems such as loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The constitution of the present invention will be described in detail below with reference to the accompanying drawings.

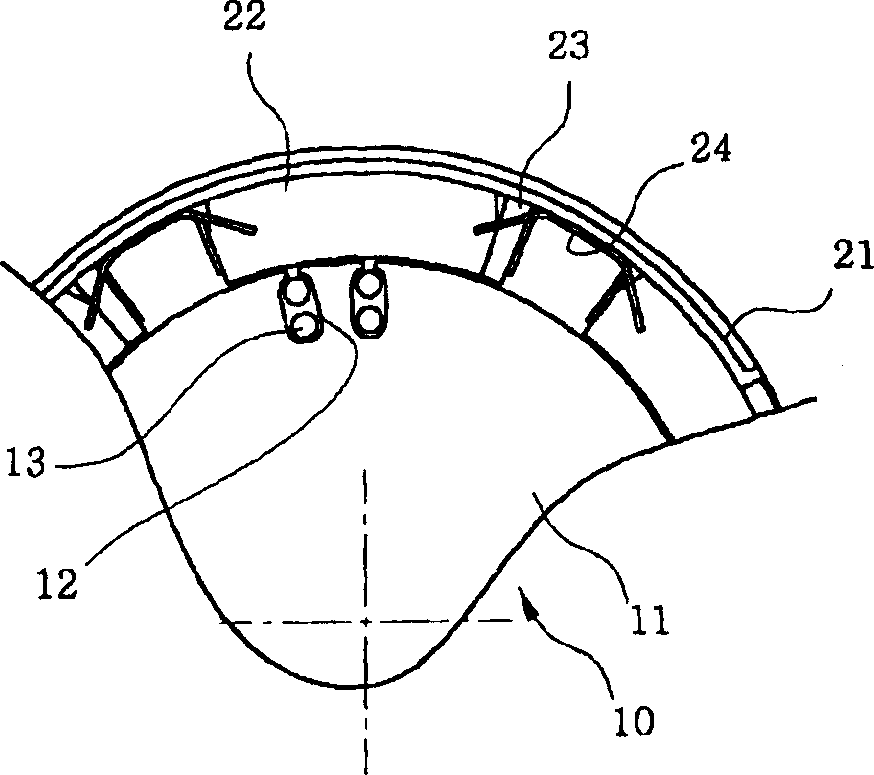

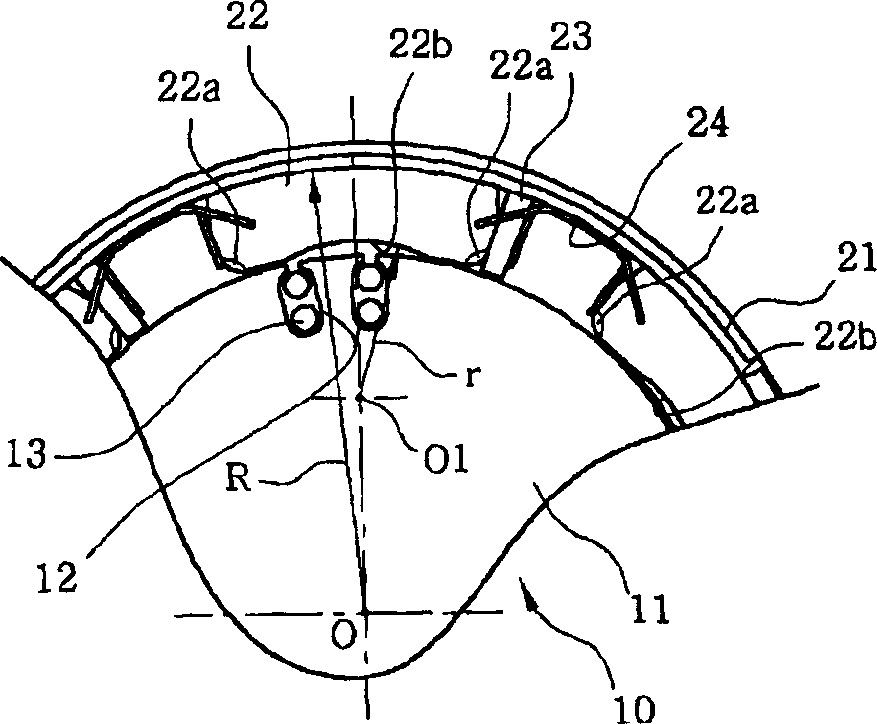

[0015] figure 1 For the cross-sectional view of the starter motor, image 3 It is a sectional view of the yoke device of the present invention, Figure 4 It is a perspective view of the magnet of the present invention, Figure 5 A cross-sectional view of the state of use.

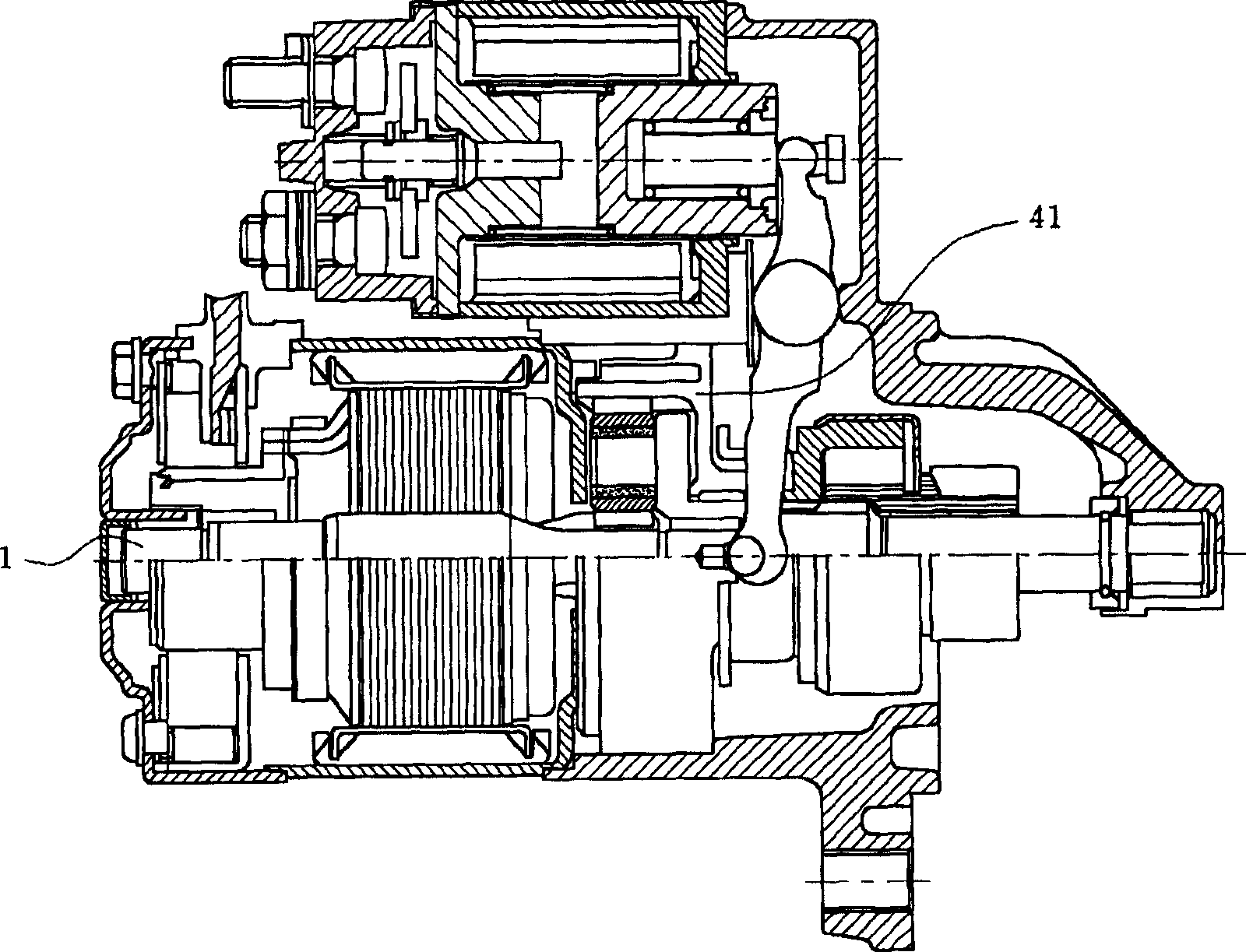

[0016] like figure 1 As shown, the starter motor consists of an armature device 10 with an iron core 11 wound with a coil 13 on the outside of the drive shaft 1, and a yoke formed by bonding a plurality of magnets 22 to the magnet 21 on the outer side of the armature device. device 20, a plurality of planetary gears 30 transmitting power from the drive shaft 1, an internal gear device 40 composed of internal gears arranged outside the planetary gears, an overrunning clutch 50 connected to the internal gears, A pinion 60 connected with the overrunning clutch and movable in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com