Method for suspension etching one face of film

A thin-film, single-sided technology, which is applied in the field of single-sided suspended corrosion thin film method, can solve the problems of metal leads being damaged and difficult to remove, such as using acid solution or alkali solution to remove them, affecting the quality of the film and the accuracy of the test, etc. , to achieve the effect of simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

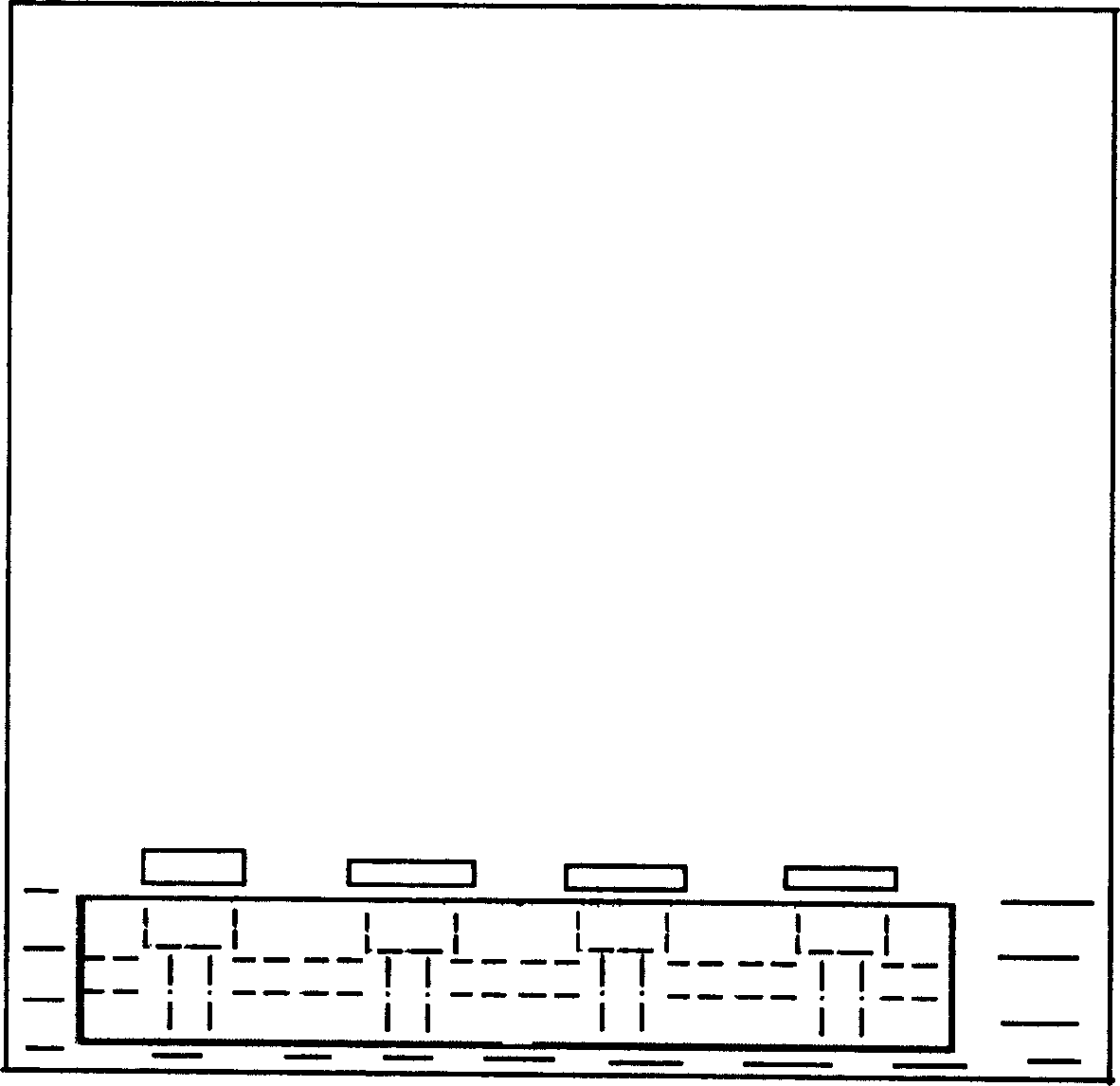

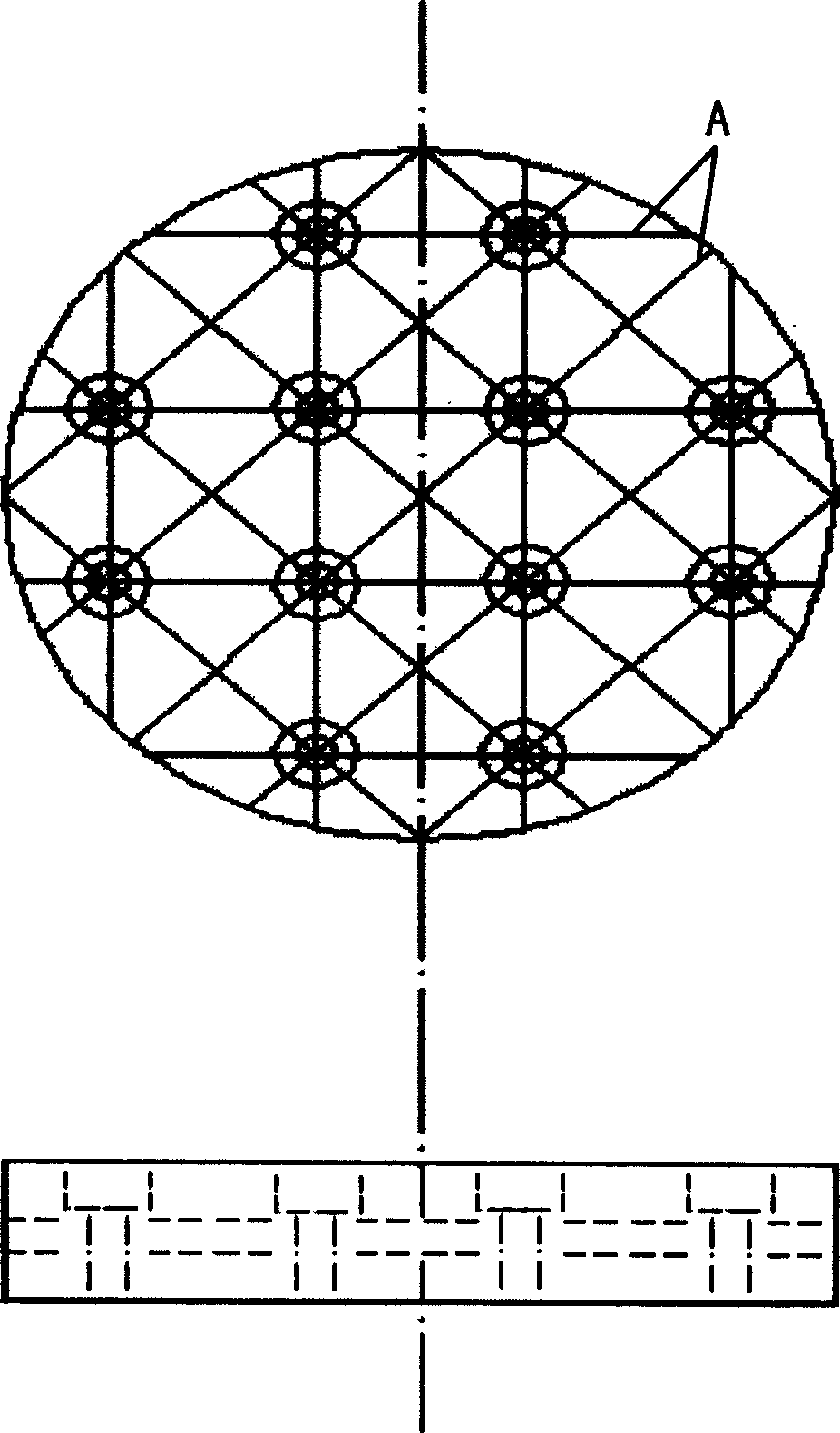

[0012] Such as figure 2 As shown, when the single-side suspension etching method is used, the etched silicon wafer has been protected with black glue (asphalt—its viscosity is high) on the side with metal leads, and the thickness of the silicon wafer is only about 20-30 μm. At this time, the silicon wafer is suspended on the etching solution for etching, the distance between the silicon wafer and the etching solution is 0-3 cm, the gas generated during the etching process will also become an upward buoyancy force, and the downward force of the silicon wafer will mainly It is affected by the pressure of the atmosphere and the gravity of the silicon wafer. Obviously, the film eliminates the pressure of the etching solution, and the gas generated will also have an upward force. Since the PTFE bracket we designed for etching has groove A, it can The gas generated under the silicon wafer can be discharged from groove A, and the film is etched in this way, so that the film reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com