Curvature radius measuring method and apparatus therefor

A technology of curvature radius and detection method, applied in the direction of measuring device, mechanical measuring device, mechanical device, etc., can solve the problems of affecting the machining accuracy of curvature, unable to completely eliminate the rebound characteristic, and unable to measure, etc., to achieve convenient measurement and simple structure , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the following embodiments and accompanying drawings.

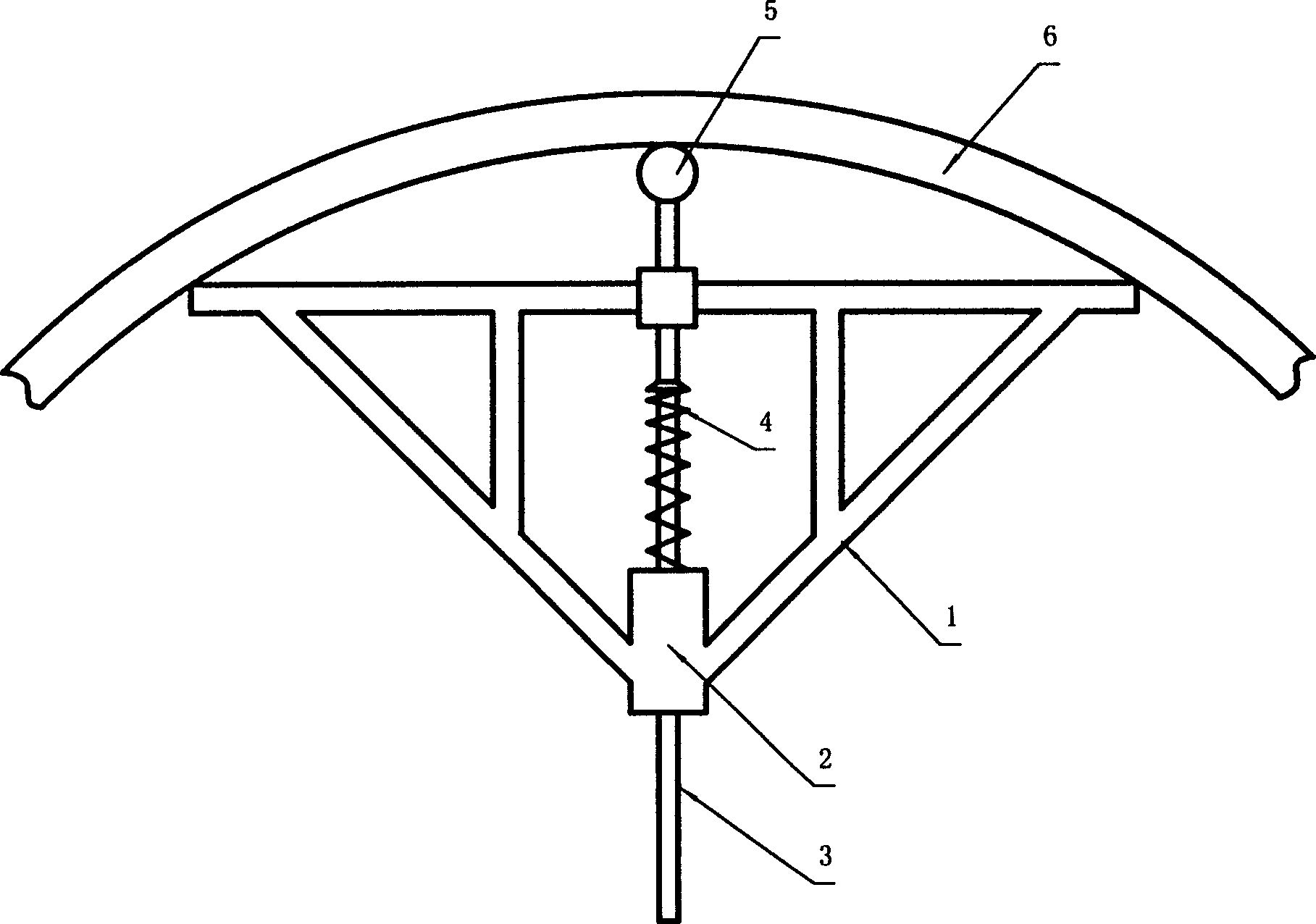

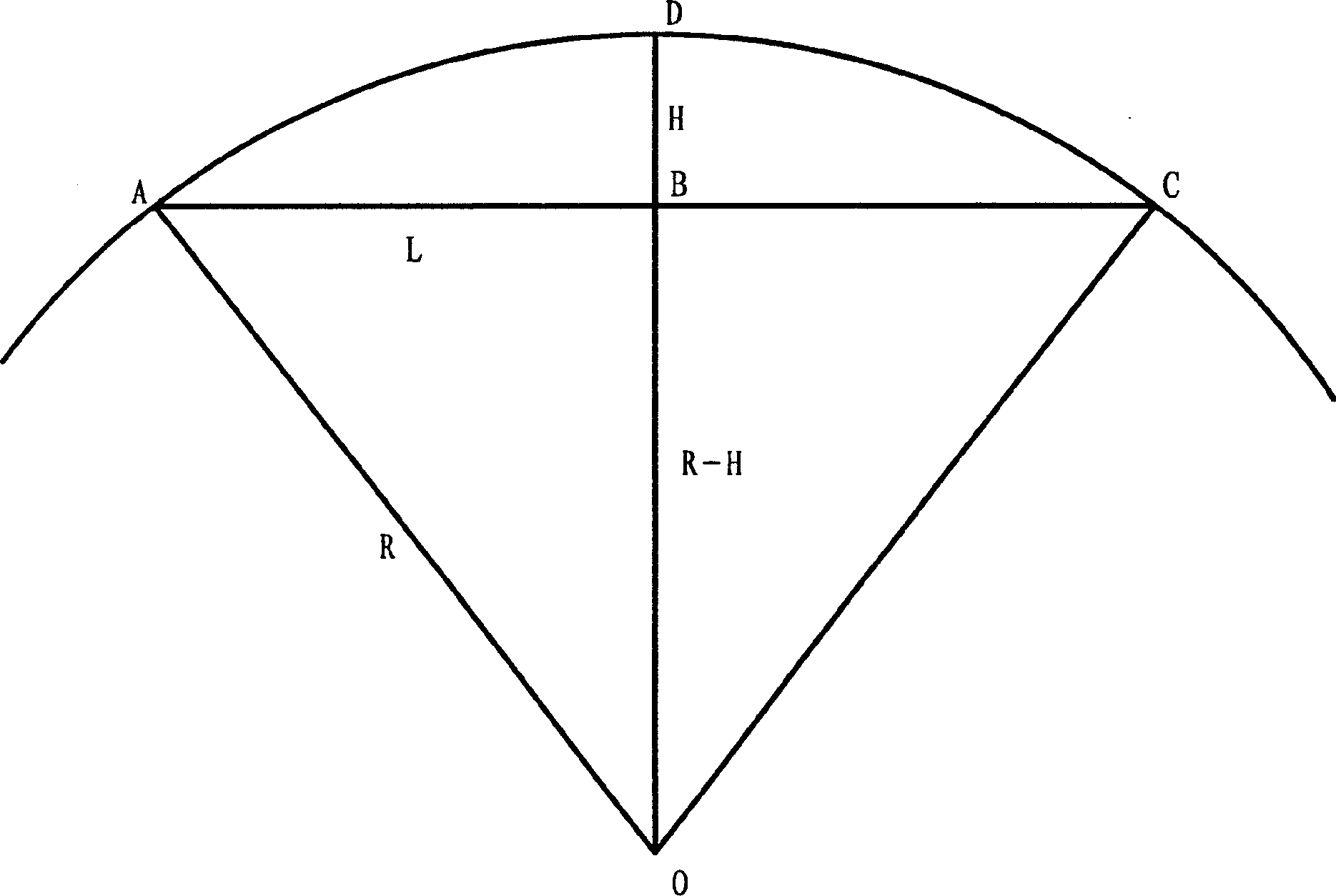

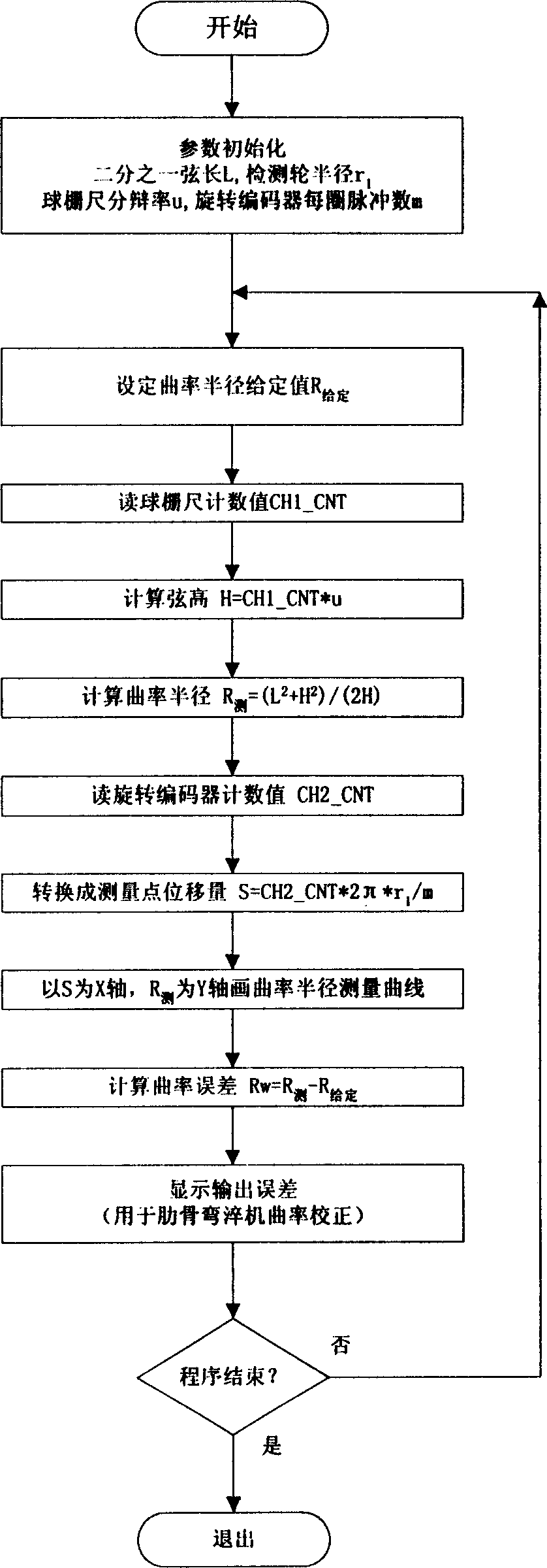

[0016] The method: use a rotary encoder coaxial with the top detection wheel of the ball scale guide rod to detect the displacement along the curve of the steel material (measured point, X axis), and use a transmitter to detect through the guide rod on the ball scale scale. The linear displacement of the steel material movement (chord height, Y axis), the rotary encoder and the transmitter respectively convert the detected signal into a TTL square wave pulse and send it to the counting card with addition and subtraction functions in the computer, and then calculate The program calculates the actual radius of curvature through the functional relationship; the counting card is inserted on the expansion slot in the computer, and is connected with the computer through the DB25 interface; the formula for calculating the radius of curvature is: R=(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com