Single stay tensing construction method and apparatus for parallel twisted steel stay system

A technology of parallel steel strands and construction methods, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., and can solve the unavoidable and repeated clamping of steel strands, the unfavorable uniformity control of steel strands, and the large space occupied by jacks To achieve the effect of improving work efficiency and economic benefits, ensuring anchoring efficiency and good anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

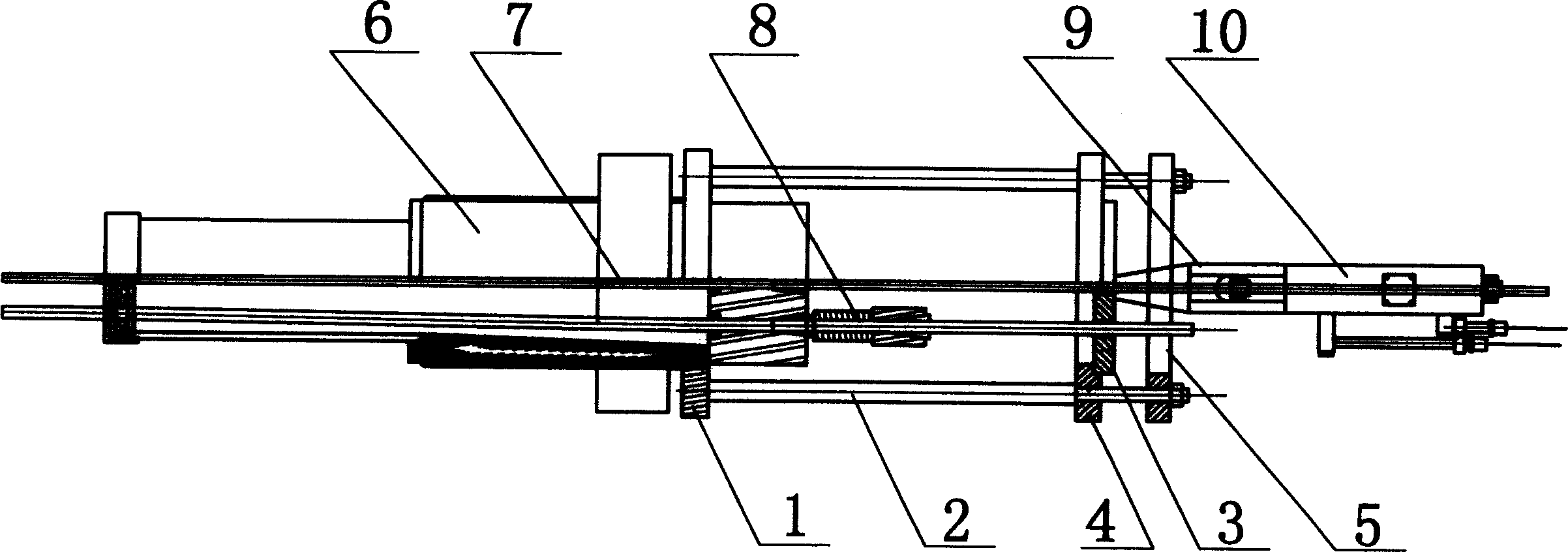

[0031] A single-root construction method for a parallel steel strand cable system. In the single-root tension construction, a support for tension and top pressure is used. The main process includes:

[0032] A: Single tension construction:

[0033] a. Fix the support to the anchor,

[0034] b. Carry out single steel strand threading and anchor with temporary clips,

[0035] c. Install a single tension jack and continuous tension components on the support,

[0036] d. Use the space inside the support to install the sensor on the anchorage,

[0037] e. Use a single tension jack and two sets of tool anchors on the continuous tension parts to repeatedly anchor the steel strands,

[0038] f. When the tension reaches the design tension, replace the formal work clamp to anchor the steel strand at one time;

[0039] B. Pushing the steel strands one by one: use the support for tensioning and pressing as the reaction force frame, so that the clips and the steel strands are jacked up...

Embodiment 2

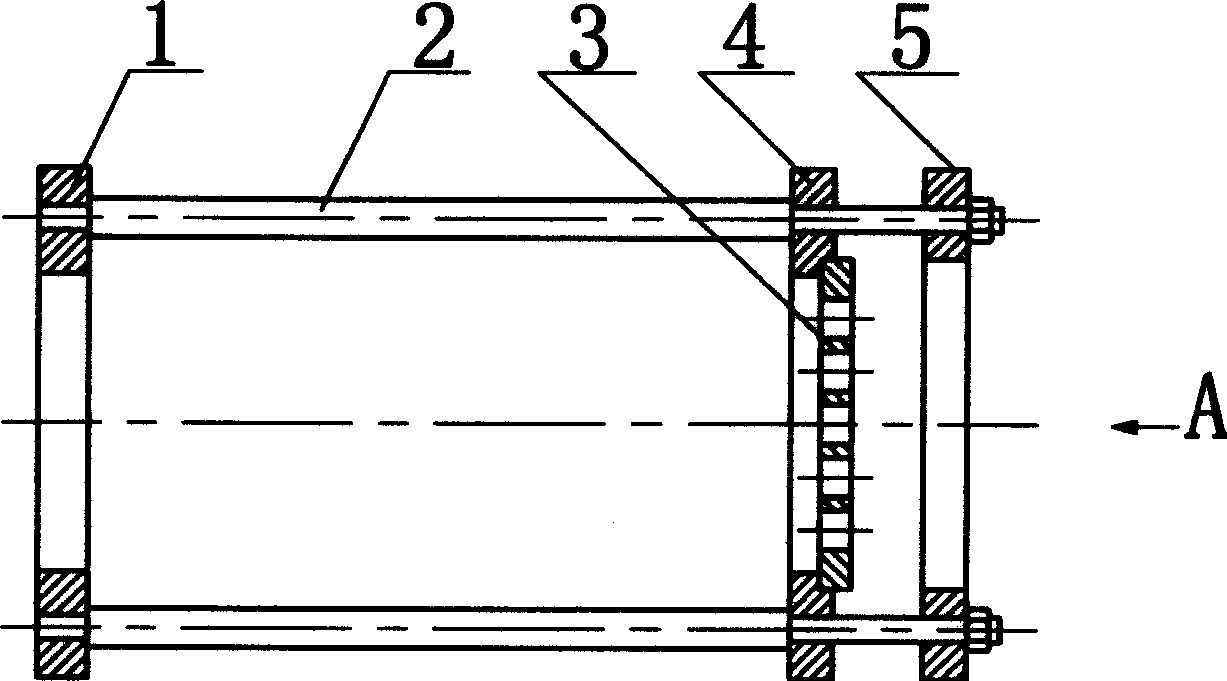

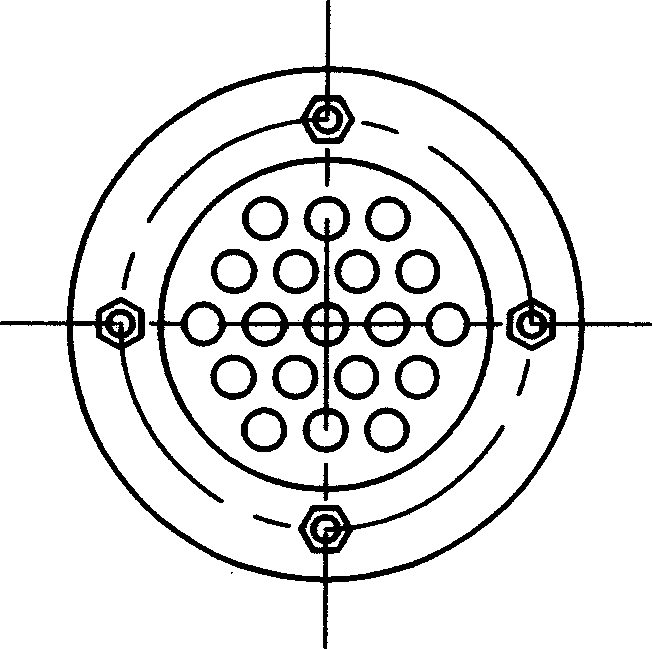

[0041] A device used in the single tension construction method of a parallel steel strand cable system-a support specially used for tension and top pressure of steel strand tension, such as figure 1 As shown, the support is composed of a connecting ring 1, a column 2, a tensioning top plate 3, a pressure bearing ring 4, and a limit ring 5. There are 3 to 6 columns in the column 2, with 4 being the best. The ring 1 and the pressure bearing ring 4 are respectively located at both ends of the column 2 and are connected into one body through the column 2. The limit ring 5 is fixed on the column 2 through nuts. The tension top pressure plate 3 is a tensile pressure plate 3, The tension bearing plate 3 is embedded in the spigot of the pressure bearing ring 4 and fixed with screws. The number of round holes corresponding to the holes of the anchor plate is drilled on it, and the circular connecting ring 1 is provided with internal threads. The top pressure support is connected with t...

Embodiment 3

[0043] A device used in a single tensioning construction method of a parallel steel strand cable system——a tensioning and top-pressing support dedicated to the steel strand top pressure. Its basic structure is the same as that of Embodiment 2, except that: The tension top plate 3 in the support for tension and top pressure is two symmetrical diaphragms 12, and each diaphragm has two rows of semicircular holes with the same number and the same position (see figure 1 , Figure 4, Figure 5).

[0044] As a modification of the various embodiments of the present invention, the coupling ring 1 can be made into a "flange" type with screw holes on it, and is connected with the anchor pad or anchor with bolts (see Figure 6).

[0045] How to install and use:

[0046] During the single tension construction, connect the connecting ring 1 of the tension and top pressure support with the anchor, insert the corresponding tension bearing plate into the seam, and adjust the hole position to cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com